iGW-1325

iGOLDEN

iGOLDEN-iGW-1325

| Availability: | |

|---|---|

ATC CNC Nesting Machine With Drilling Description:

This ATC CNC Nesting Machine with Drilling is good at wood drilling and cutting. The drilling head is equpped with 9 vertical and 3 horizontal drill bits and 1 saw blade. It makes the drilling and cutting process more efficient and saves more time. ATC is essential for automatical woodworking, which greatly reduces non-production time and save human labors. This is the best machine combination for furniture, cabinet and door making.

Atc CNC Nesting Router Machine With Vertical Drilling Features:

1. Air cooling spindle with high speed,high efficency and little noise.

2. It's with loading and unloading nesting system, so can save time and have high effiency.

3. Taiwan HIWIN square guide rails and Taiwan TBI ball screws with high precision,large load bearing and stable running.

4. Equipped with professional vaccum adsorption base with the high strength engineering plastics surface in order to ensure can bear large load and longtime working.

5. Adopt high powerful professional vacuum pump,strong adsorption capacity.

Parameter Configuration Of Nesting CNC Router ATC Tool Changer With Drilling Wood Machine:

Working Area | 1300*2500*300mm |

Machine structure | G6 bed column |

Spindle | HQD 9KW air cooling Automatic tool change+9 holes vertical drilling |

Spindle Speed | 0-18000 rpm |

Inverter | FULING |

Guide rail | PEK |

Reducer | Taiwan SHIMPO |

Working table | Double vacuum suction table |

Control system | Taiwan LNC |

Vacuum pump | 7.5KW water vacuum pump |

Max idle speed | 50000mm/min |

Max engraving speed | 20000mm/min |

Voltage | AC 380V-50HZ |

Weight | 2500KG |

Advantages Of ATC CNC Router With A Drilling Head :

Increases plate utilization by 40%. The CNC cutting machine is embedded with a milling cutter to penetrate the material, which is randomly pivoted to penetrate uniquely shaped workpieces and bolster the application rate of the plate.

Reduces Labor costs. Only one person operates multiple nesting CNC machines simultaneously or at varying rates, which greatly cuts the labor costs by a huge margin.

Reduces labor intensity. With its inbuilt automatic loading and unloading functionality, the nesting CNC device simplifies work and reduces tasks of the workers in a factory-like setting.

High safety factor. Sometimes negligence from a CNC router operator leads to unnecessary injuries due to lesser attention devoted to working while using the items like the table saw. However, the inbuilt safety factor of the opener guarantees protection from any search accident or injury.

Efficient vacuuming effect. The nesting CNC machine is furnished with a dual-cylindrical vacuum cleaner, this facilitates cleaning by a whooping a 3-5 times higher than that of the common table saw.

Higher productivity. The nesting CNC machine embraces full automatic loading and unloading concurrently, and even handles workloads of 1.5 times that of ordinary manual opening. Finally, blue-collar workers’ involvement in nesting cnc machine processing, cuts labor intensity while boosting production efficiency.

Robust, balanced structure ensuring maximum stability. Specially-designed technologies to guarantee precision and rigidity. The heavy monolithic base guarantees solidity and absence of vibration, for consistent product quality over time.

The Gantry structure with the dual engine is designed to increase precision and reliability standards for the execution of machining operations.

Automatic lubrication is an option that ensures the continuous lubrication of the nesting cnc router machine’s main moving parts without the need for operator intervention.

The double Y-axis motorization supports high speeds and accelerations whilst ensuring high precision and quality. Higher motor power increases acceleration at3m/s2 and speeds 85m/min.

Loading and unloading systems are carried out simultaneously allowing the operator to remove completed components from the unloading station with the utmost safety whilst the nesting cnc router is already processing the next panel. Panel loading system with scissor lift and automatic panel alignment. The system’s ease of use ensures long term reliability.

The loading and unloading panels that automate and optimize the machining process with a footprint that is reduced by up to 40%.

CNC nesting router’s size is customizable depends on the customer’s panel size. We can build such as 1300*2500mm,1500*3000mm,2000*3000mm,2000*4000mm and so on

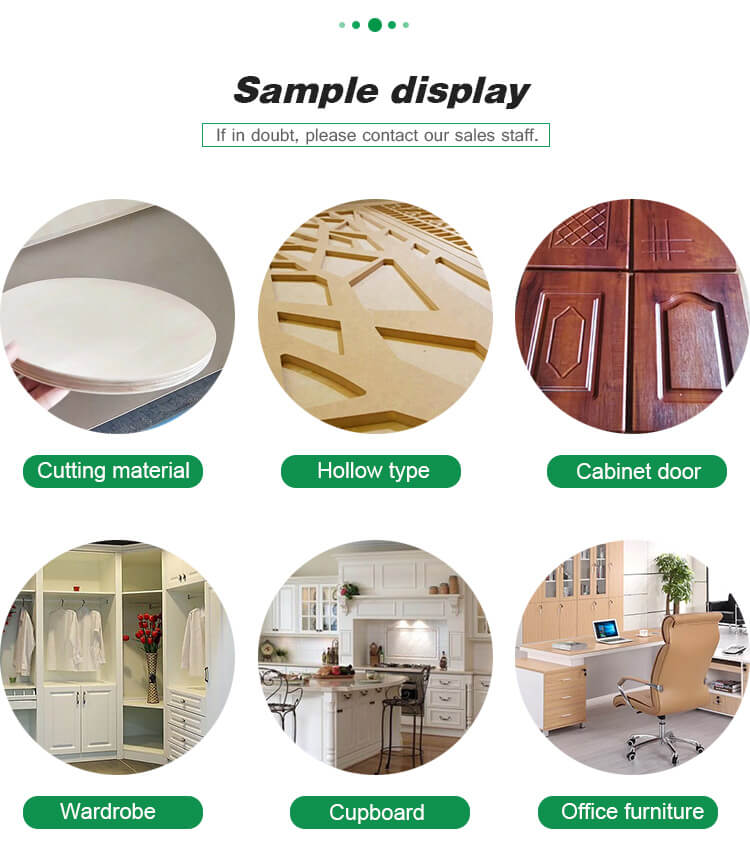

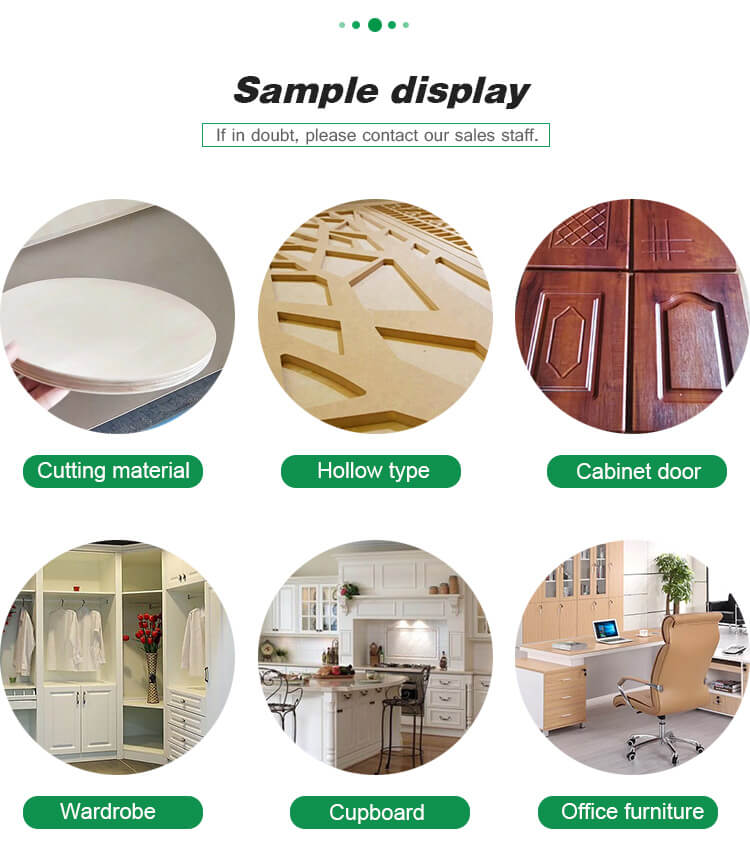

CNC Nesting Machine With Drilling Applications:

1. Furniture: cabinet doors, solid wood doors, craft wooden doors, paint-free doors, screens, craft fan windows, tables, chairs, etc. Wooden door cutting, wooden door artwork carving, wave board, 3d photo carving, small or large relief works, cylindrical wood carving, 3d photo carving, etc.

2. Advertising industry: advertising signs and logos, decorative products, wood, medium density fiberboard, bamboo, plastic, PVC, acrylic, metal, stone, etc.

3. Art industry: character carving, character carving and cutting, famous brand making, small gift cutting, souvenir making, carving various decorative letters, small windows, fences, figures on walls, etc.

4. Model making: engraving metal molds such as copper, aluminum and iron, as well as non-metal molds such as marble, sandstone, plastic plates, PVC pipes and wood panels.

5. Other industries: CNC wood engraving machine can engrave all kinds of large reliefs and shadows, which are widely used in craft gift industry.

Shandong iGolden CNC Technology Co., Ltd. is a R&D,manufacturing,sales integration company that specializing in cnc router, laser engraving and cutting machine, plasma cutting machine, cutting plotter,etc.The main configuration all adopt top parts which imported from Italy, Japan,Germany,etc. And welcome to visit us for more choices.

FAQ:

1.What's the advantages of the Nesting CNC machine?

First of all, there are twelve tool changes, which can process more complicated engraving. The 4 + 5 row drill package can punch nine holes with different diameters. The punching speed is fast.

2.What is the application of machining center drilling bank?

The doors and cabinets of the machining center can be processed. Compared with other numerical control equipment, it can process tedious processes, and the processing speed is greatly improved.

3.Will the equipment be eliminated in the future?

In the customer groups we are currently in contact with, we do not require the processing of hundreds of plates per day, and they are generally not eliminated. Each of our customer groups does not require individualization, and most of them are personalized. Home improvement companies, decoration industries, etc., customer requirements will be met. Compared with other CNC equipment, its advantages are still great, and will not be eliminated in the short term.

If you want to save labor, it is best to add an automatic loading and unloading platform. If the customer considers the cost of equipment purchase, you can suggest that you add a loading platform and build a loading platform yourself. This saves labor and costs.

5.Does the spindle and drill use imported HSD?

Our domestic equipment has more options to use domestic first-line HQD spindle drilling, his warranty is long, and in use, the spindle is damaged. We can re-issue spares without delaying production. The imported spindle is quite high in maintenance time and cost. The stability and efficiency of domestic spindles are also guaranteed. I still recommend the boss to choose domestic HQD, of course, if you still consider importing spindle drilling, sufficient investment funds can configure you for import.

ATC CNC Nesting Machine With Drilling Description:

This ATC CNC Nesting Machine with Drilling is good at wood drilling and cutting. The drilling head is equpped with 9 vertical and 3 horizontal drill bits and 1 saw blade. It makes the drilling and cutting process more efficient and saves more time. ATC is essential for automatical woodworking, which greatly reduces non-production time and save human labors. This is the best machine combination for furniture, cabinet and door making.

Atc CNC Nesting Router Machine With Vertical Drilling Features:

1. Air cooling spindle with high speed,high efficency and little noise.

2. It's with loading and unloading nesting system, so can save time and have high effiency.

3. Taiwan HIWIN square guide rails and Taiwan TBI ball screws with high precision,large load bearing and stable running.

4. Equipped with professional vaccum adsorption base with the high strength engineering plastics surface in order to ensure can bear large load and longtime working.

5. Adopt high powerful professional vacuum pump,strong adsorption capacity.

Parameter Configuration Of Nesting CNC Router ATC Tool Changer With Drilling Wood Machine:

Working Area | 1300*2500*300mm |

Machine structure | G6 bed column |

Spindle | HQD 9KW air cooling Automatic tool change+9 holes vertical drilling |

Spindle Speed | 0-18000 rpm |

Inverter | FULING |

Guide rail | PEK |

Reducer | Taiwan SHIMPO |

Working table | Double vacuum suction table |

Control system | Taiwan LNC |

Vacuum pump | 7.5KW water vacuum pump |

Max idle speed | 50000mm/min |

Max engraving speed | 20000mm/min |

Voltage | AC 380V-50HZ |

Weight | 2500KG |

Advantages Of ATC CNC Router With A Drilling Head :

Increases plate utilization by 40%. The CNC cutting machine is embedded with a milling cutter to penetrate the material, which is randomly pivoted to penetrate uniquely shaped workpieces and bolster the application rate of the plate.

Reduces Labor costs. Only one person operates multiple nesting CNC machines simultaneously or at varying rates, which greatly cuts the labor costs by a huge margin.

Reduces labor intensity. With its inbuilt automatic loading and unloading functionality, the nesting CNC device simplifies work and reduces tasks of the workers in a factory-like setting.

High safety factor. Sometimes negligence from a CNC router operator leads to unnecessary injuries due to lesser attention devoted to working while using the items like the table saw. However, the inbuilt safety factor of the opener guarantees protection from any search accident or injury.

Efficient vacuuming effect. The nesting CNC machine is furnished with a dual-cylindrical vacuum cleaner, this facilitates cleaning by a whooping a 3-5 times higher than that of the common table saw.

Higher productivity. The nesting CNC machine embraces full automatic loading and unloading concurrently, and even handles workloads of 1.5 times that of ordinary manual opening. Finally, blue-collar workers’ involvement in nesting cnc machine processing, cuts labor intensity while boosting production efficiency.

Robust, balanced structure ensuring maximum stability. Specially-designed technologies to guarantee precision and rigidity. The heavy monolithic base guarantees solidity and absence of vibration, for consistent product quality over time.

The Gantry structure with the dual engine is designed to increase precision and reliability standards for the execution of machining operations.

Automatic lubrication is an option that ensures the continuous lubrication of the nesting cnc router machine’s main moving parts without the need for operator intervention.

The double Y-axis motorization supports high speeds and accelerations whilst ensuring high precision and quality. Higher motor power increases acceleration at3m/s2 and speeds 85m/min.

Loading and unloading systems are carried out simultaneously allowing the operator to remove completed components from the unloading station with the utmost safety whilst the nesting cnc router is already processing the next panel. Panel loading system with scissor lift and automatic panel alignment. The system’s ease of use ensures long term reliability.

The loading and unloading panels that automate and optimize the machining process with a footprint that is reduced by up to 40%.

CNC nesting router’s size is customizable depends on the customer’s panel size. We can build such as 1300*2500mm,1500*3000mm,2000*3000mm,2000*4000mm and so on

CNC Nesting Machine With Drilling Applications:

1. Furniture: cabinet doors, solid wood doors, craft wooden doors, paint-free doors, screens, craft fan windows, tables, chairs, etc. Wooden door cutting, wooden door artwork carving, wave board, 3d photo carving, small or large relief works, cylindrical wood carving, 3d photo carving, etc.

2. Advertising industry: advertising signs and logos, decorative products, wood, medium density fiberboard, bamboo, plastic, PVC, acrylic, metal, stone, etc.

3. Art industry: character carving, character carving and cutting, famous brand making, small gift cutting, souvenir making, carving various decorative letters, small windows, fences, figures on walls, etc.

4. Model making: engraving metal molds such as copper, aluminum and iron, as well as non-metal molds such as marble, sandstone, plastic plates, PVC pipes and wood panels.

5. Other industries: CNC wood engraving machine can engrave all kinds of large reliefs and shadows, which are widely used in craft gift industry.

Shandong iGolden CNC Technology Co., Ltd. is a R&D,manufacturing,sales integration company that specializing in cnc router, laser engraving and cutting machine, plasma cutting machine, cutting plotter,etc.The main configuration all adopt top parts which imported from Italy, Japan,Germany,etc. And welcome to visit us for more choices.

FAQ:

1.What's the advantages of the Nesting CNC machine?

First of all, there are twelve tool changes, which can process more complicated engraving. The 4 + 5 row drill package can punch nine holes with different diameters. The punching speed is fast.

2.What is the application of machining center drilling bank?

The doors and cabinets of the machining center can be processed. Compared with other numerical control equipment, it can process tedious processes, and the processing speed is greatly improved.

3.Will the equipment be eliminated in the future?

In the customer groups we are currently in contact with, we do not require the processing of hundreds of plates per day, and they are generally not eliminated. Each of our customer groups does not require individualization, and most of them are personalized. Home improvement companies, decoration industries, etc., customer requirements will be met. Compared with other CNC equipment, its advantages are still great, and will not be eliminated in the short term.

If you want to save labor, it is best to add an automatic loading and unloading platform. If the customer considers the cost of equipment purchase, you can suggest that you add a loading platform and build a loading platform yourself. This saves labor and costs.

5.Does the spindle and drill use imported HSD?

Our domestic equipment has more options to use domestic first-line HQD spindle drilling, his warranty is long, and in use, the spindle is damaged. We can re-issue spares without delaying production. The imported spindle is quite high in maintenance time and cost. The stability and efficiency of domestic spindles are also guaranteed. I still recommend the boss to choose domestic HQD, of course, if you still consider importing spindle drilling, sufficient investment funds can configure you for import.