Views: 9 Author: Site Editor Publish Time: 2022-05-09 Origin: Site

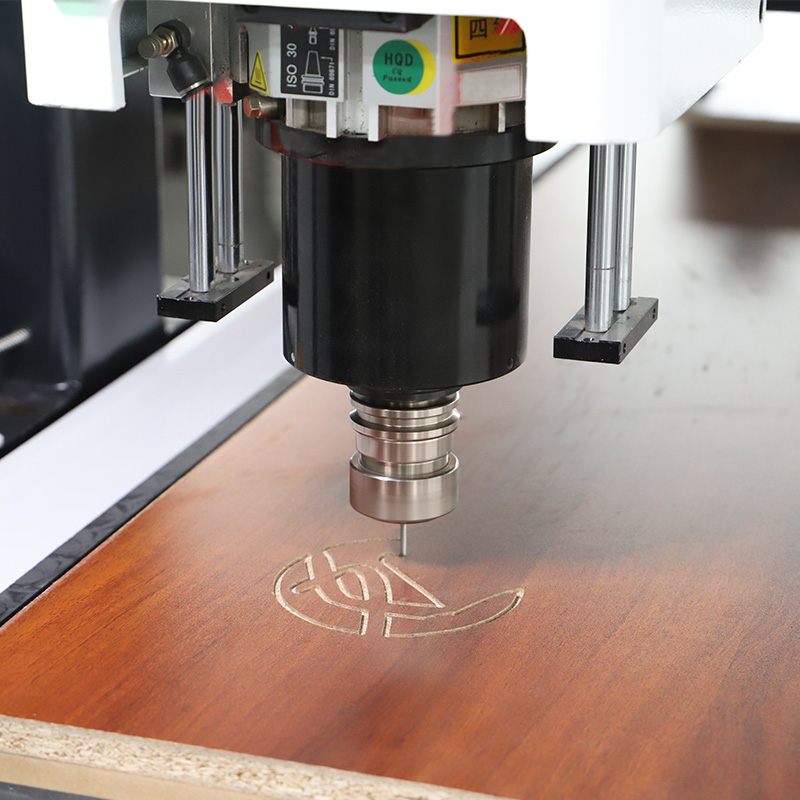

4x8 cnc router with tool changer is driven by all-digital AC servo motor. It has the advantages of high speed, high precision, high response, quiet and balanced operation; it can realize precise position control, speed control, torque control; support MODBUS communication protocol, adopt RS-232/RS-485 communication interface; provide rigid meter Setting, inertia identification and vibration suppression functions are simple and easy to use; it adopts precision planetary reducer, which has small size, low noise, high output torque and long life; it adopts high quality limit switch, which is sensitive in induction and fast in feedback. This type of Automatic tool changer CNC router can meet the tool change requirements during processing without manual involvement.

Many of the more advanced atc cnc include an entire maintenance log covering daily, weekly and monthly inspections. Contingent upon the type and make of router, maintenance schedules tend to vary but the following five guidelines apply to all machines:

Cleanliness: Routers invariably operate in a dusty environment and it does not take long for bearings and controls to become polluted and this is a sure recipe for operating problems if not rectified on a daily basis.

Manufacturers and suppliers recommend hand-sweeping of the router, while an air gun can be used to blow debris away from the bearings. Another fairly standard recommendation is to lower the air pressure during the cleaning process.

Change filters: If this sounds like an instruction found in an automobile manual there is a reason for the similarity. Just as clogged filters reduce engine efficiency, the same applies to a router’s controller, vacuum pumps and air lines. The frequency with which filters are replaced will vary, depending on the type of material being processed and environmental factors like the presence of dust and dirt. There is no standardised maintenance protocol but as a rule of thumb filters should be checked weekly and replaced as considered necessary.

Lubrication: This is a fairly basic consideration that can sometimes be overlooked. Generally, routers do not require extensive lubrication but as with all production machinery breakdowns are inevitable if adequate lubrication is not carried out.

An important consideration for router owners is that if it is found that a machine malfunction was caused by a failure to lubricate sufficiently the manufacturer’s warranty would be voided. Bearings, pumps, router spindles and knives need regular lubrication, but the frequency with which this is carried out will again be influenced by the type and make of machine, the extent of its use and the work environment in which it operates.

Air supply cleaning: Most routers operate using air that has to be clean, dry and maintained at a steady pressure exceeding 80psi or six barometric. Damage to the router is likely in the short term if air pressure is not checked regularly and maintained at the recommended level.

Safe and appropriate electrical power: The caveat for electrically-powered machines applies equally to CNC routers, with the power connected safely as required by local regulations. Router failure is likely to occur in cases of poor electrical grounding, low voltage or insufficient capacity. As with all computer-operated machinery, power spikes will cause serious damage.

Daily and weekly maintenance protocols invariably come with every CNC router. They include times for logging operation hours, general cleaning, air pressure readings and lubrication. Monthly inspection protocols include greasing of the racks, pinions and bearings, repair or replacement of the vacuum table gasket should this be necessary and cleaning of all filters.

In addition, bi-annual maintenance protocols include replacement of all filters, vacuum performance testing and inspection and tightening of timing belts and transmissions.

4x8 cnc router with tool changer applications:

Applicable Field

The ATC router machines with drill heads are usually applied to fabricate wooden door panels, cabinets, office furniture, bedroom furniture, and other panel furniture.

Materials Good For

All types of wood board/sheet.

Machining Capacity

Routing, milling, drilling, drilling on four sides, and grooving.