Views: 10 Author: Site Editor Publish Time: 2020-10-20 Origin: Site

Today, I will introduce the best-selling laser machines in the CNC laser field. Nowadays, laser machines are widely used in various industries. I believe that no matter which industry you are in, there will always be a laser machine suitable for you. Below we mainly analyze the different processing principles of laser machines, processing advantages and what these laser machines can do. Therefore, if you want to buy a laser machine now, or are in the laser industry, then this article will also help you choose the right laser machine.

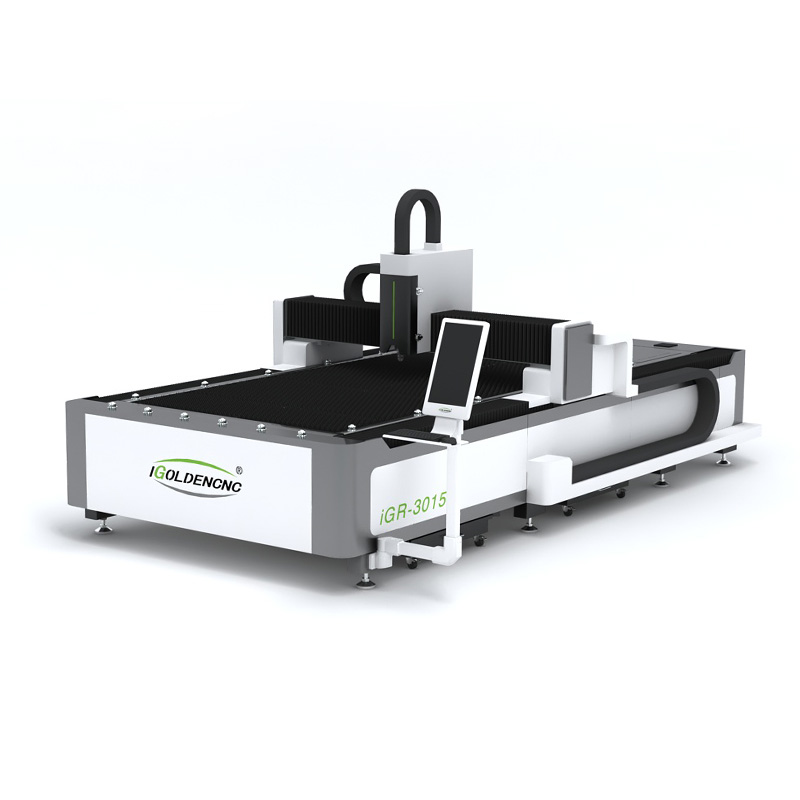

The most common type of laser machine is the laser cutting machine. The laser cutting machine uses the laser beam emitted by the laser to focus into a high-power density laser beam through the optical path system to work. The laser beam irradiates the surface of the workpiece to generate heat, and the workpiece reaches its own melting point or boiling point, and the high-pressure gas blows away the molten or vaporized useless metal. As the relative position of the laser beam and the workpiece moves, the material is finally processed into a slit. So as to achieve the purpose of cutting you want..

Processing advantages of laser cutting machine:

1. High cutting precision. It is suitable for processing precision parts and fine cutting, suitable for complex pattern carving. 2. Fast cutting speed. The cutting speed can reach 10-12m/min. 3. Good cutting quality. The cutting spindle will not directly contact the material. Non-contact cutting is used to ensure that the workpiece will not be thermally deformed or scratched, and generally does not require secondary processing. 4. High cutting precision. The error accuracy of the metal laser cutting machine is within 0.05 mm, and the repeat positioning accuracy is within 0.03 mm. 5. Smooth cutting surface, no burrs on the cutting surface. 6. Diverse processing functions. The fiber laser cutting machine can process any graphics you want, and can cut any shape of material, such as pipes, without being affected by the outer contour of the workpiece.

Application range of laser cutting machine: Laser cutting machine can process carbon steel, stainless steel, aluminum, aluminum alloy, aluminum plate, galvanized plate, copper and most other metal materials. It is widely used in the production of advertising signs, electrical cabinets, machinery parts, kitchen appliances, automobile industry, machinery industry, metal crafts, electrical parts, hardware and other industries. In addition, laser cutting machines can also be used in high-tech industries such as aerospace, shipbuilding, agricultural machinery, precision machinery, environmental protection equipment, medical equipment, furniture, lighting, metal crafts, ceilings, curtain walls, electrical cabinets and other industries.

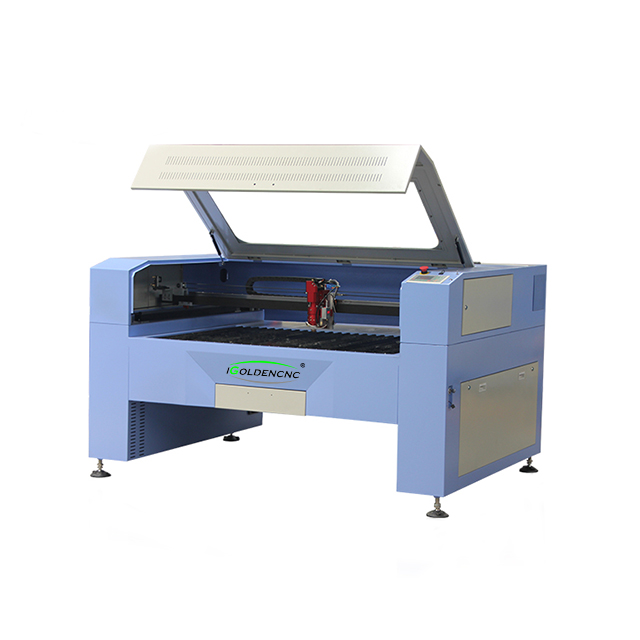

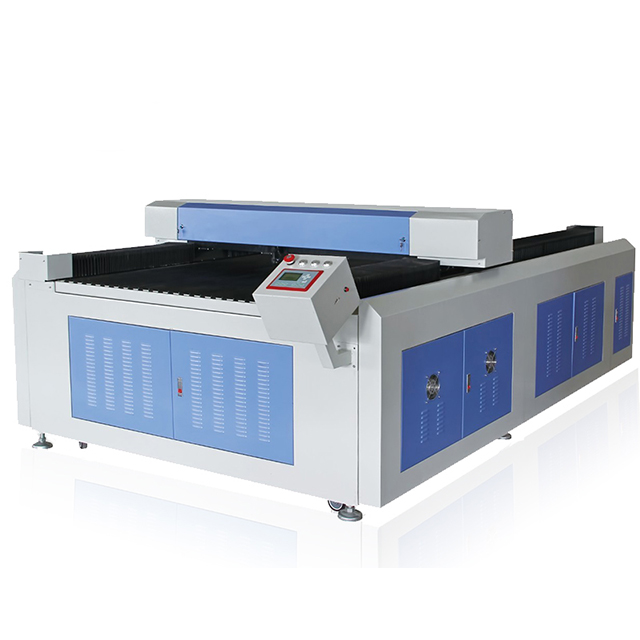

The second most popular type of laser machine is the laser engraving machine. Laser engraving machine is an advanced equipment based on CNC technology, which uses laser to engrave materials that need to be engraved. Under laser irradiation, the processed material will physically melt and vaporize to achieve the purpose of engraving. The working method of laser engraving machine is also different from ordinary CNC mechanical engraving machine and traditional manual engraving. The laser engraving machine also uses non-contact processing. The cutting head is not in contact with the surface of the material, the material will not deform, and is not affected by mechanical movement, so it usually does not need to be fixed. In addition, the laser engraving machine can process a variety of different processing materials without being limited by the elasticity and flexibility of the material.

Processing advantages of laser engraving machine:

1. Wide range of applicable processing. The laser engraving machine can engrave almost all non-metallic materials, including crystal, paper, plexiglass, marble, cloth, leather, rubber, plastic, etc. It can also engrave some metal materials, such as steel plate, aluminum, copper, etc. 2. The processing process has high safety and low pollution. The laser engraving machine uses non-contact processing to ensure the safety of materials. The diameter of the beam and spot is small, usually within 0.5mm, which saves material. 3. Good processing quality. The processing precision of the laser engraving machine can reach 0.02mm, and the heat affected zone is small. 4. High speed and fast. High-speed engraving can be carried out immediately according to the patterns output by the connected computer. 5. Lower cost. Processing is not limited by the number of materials and is suitable for batch processing. If you want to process small batches of parts, laser machining will be more affordable.

Application range of laser engraving machine: Laser engraving machines are widely used in clothing, embroidery, dolls, toys and other processing industries. In addition, laser engraving machines have been widely used in kitchens, advertising, decoration, electrical appliances, furniture, handicrafts, models and other industries in recent years.

The third common type of laser machine is a laser marking machine. Laser marking uses a laser beam to permanently mark the surface of various materials. The working principle is to evaporate the surface layer material by a laser beam to expose the deep layer material, or through the chemical change of the surface layer material caused by light energy to produce engraving traces, or to display the pattern and text you want to engrave by burning off part of the material .

Processing advantages of laser marking machine: 1. Mark a variety of materials. The material application range of laser marking machine is very wide. It can mark metals, plastics, ceramics, glass, paper, leather, etc. Both soft and hard materials can be marked. 2. Diversified functions. The laser marking machine is very practical and can be used in conjunction with a variety of machines. It can be used with other equipment on the production line to improve the degree of automation and work efficiency. 3. Good marking effect. The marking pattern is clear, durable, beautiful, and effective anti-counterfeiting. 4. The new laser marking machine replaces the traditional inkjet technology, saves unnecessary consumables, has a long service life, is pollution-free and environmentally friendly. 5. Low operating cost. Marking once, consumes less resources and the marking speed is fast. 6. High marking efficiency. By operating the computer to control the laser beam, the laser beam can move at a high speed, and the marking process can be completed in a few seconds. Laser technology can be well combined with computer technology. Users only need to input the programmed program on the computer to achieve laser printing output, and can change the design they want to print at any time. 7. High processing precision. The light beam emitted by the laser marking machine is very thin, and the thinnest line width can reach the micron level, acting on the surface of the material, thereby realizing precision processing. 8. The laser marking machine can meet the needs of printing a large number of patterns, texts and letters on very small parts.

Application range of laser marking machine:

Laser marking machines are now mainly used in the IT industry, communications industry, machinery manufacturing, food and pharmaceutical packaging, medical equipment, craft gifts, metal jewelry, leather clothing, packaging and printing and other metal processing industries. It can also be used in non-metal processing industries, such as clothing, leather, craft gifts, wood, textiles, plastics, signs, printing and decoration industries.

Through the above article, I believe you have a general understanding of the types of laser machines. If you want to buy these laser machines, we are a professional CNC machine tool manufacturer, we can provide you with professional equipment and give you professional technical guidance.

content is empty!