Views: 103 Author: Site Editor Publish Time: 2023-03-01 Origin: Site

iGOLDEN top rated fiber laser cutting machine is designed for metal fabrication, including steel, aluminum, titanium, alloy, brass, copper, and iron, with different laser powers(1000W, 1500W, 2000W, 3000W, 4000W, 6000W, 8000W, 12000W, 20000W). The affordable fiber laser cutter is for sale at a low price, with the best fiber laser cutting system service and support.

iGR-F fiber laser cutting machine for sheet metal is a high-performance industrial laser cutting tool that utilizes the latest advances in laser technology to deliver quick and accurate cuts on sheets of metals.The machine is high powered that works with really high speed to give the most precise cutting in less time, making the machine a low-cost investment with respect to its productivity.

Fiber laser cutting machine for metal sheet includes a cooling, lubricating and dust collection system guaranteeing durability and longevity. The strict assembly process and the world’s top brand parts ensure high cutting precision and powerful cutting ability, so as to maximize the productivity and profitability of sheet metal fabricators. iGOLDENCNC also stocks metal sheet & tube cutting laser machine that has dual purpose and is able to handle both sheets & tubes simantenously.

The fiber laser cutting machine process replaces the traditional mechanical knife with an invisible beam. It has the characteristics of high precision, fast cutting, not limited to the cutting pattern, automatic typesetting to save materials, smooth incision, low processing cost, etc. It will be gradually improved or replaced in Traditional metal-cutting process equipment. The mechanical part of the laser cutter head has no contact with the workpiece and will not scratch the surface of the workpiece during work. The laser cutting speed is fast.

A fiber laser cutting machine is a type of cutting tool that uses a high-power fiber laser to cut metal sheets. It works by directing the laser beam through a series of mirrors and lenses, which focus the beam onto the material to be cut.

The advantages of using a fiber laser cutting machine for metal sheet cutting include:

High precision: Fiber laser cutting machines can cut materials with high precision, up to a few microns.

High speed: The high power of the fiber laser allows for fast cutting speeds, which can increase productivity and reduce production time.

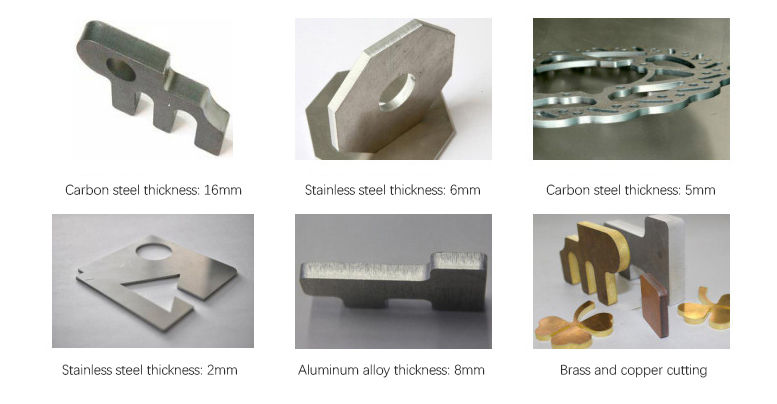

Versatility: Fiber laser cutting machines can cut a variety of materials, including steel, aluminum, brass, copper, and other metals.

Low maintenance: Compared to other cutting methods, fiber laser cutting machines require less maintenance and have a longer lifespan.

Low operating costs: Fiber lasers are energy-efficient and require less power than other types of lasers, which can result in lower operating costs.

When choosing a fiber laser cutting machine for metal sheet cutting, consider factors such as the size and thickness of the material, the desired cutting speed, and the level of precision required. It's also important to select a machine with a high-quality laser source and reliable cutting software.

The incision is smooth and flat and generally does not require subsequent processing; the cutting heat-affected zone is small, the plate deformation is small, and the slit is narrow ( 0.1mm~0.3mm). The incision has no mechanical stress and no shearing burrs. Fiber laser cutting machine has the advantages of high machining accuracy, good repeatability, and no damage to the material’s surface. CNC programming can process any plan and cut the entire board in a large format without opening the mold, which is economical and time-saving. The laser beam is irradiated on the surface of the workpiece, making the workpiece reach the melting point or boiling point, while the high-pressure gas coaxial with the shaft blows the molten or vaporized metal away. When the relative position of the laser beam and the workpiece moves, the material will form a slit to achieve the purpose of cutting.

Fiber laser cutter is also known as fiber laser cutting machine, fiber laser cutting system, which is a CNC laser machine that uses fiber laser beam to cut metal materials to different shapes, it is controlled by a computer with a laser software, you can input your designed files to the software, the software will send a command to the machine, then it will run according to the command, a 2D or 3D shape will be output in minutes. You can choose different machines with different powers to fit materials with different thickness, you can also choose different machines with different size to fit materials with different size. It is equipped with laser power from 1000 Watts to 15000 Watts to cut metal materials. Fiber laser cutter is mainly divided into mini series, hobby series, small series, portable series, large format series according to sizes. Fiber laser cutter is mainly divided into sheet metal laser cutter types, laser tube cutter types according to applications.