Views: 5 Author: Site Editor Publish Time: 2022-05-06 Origin: Site

Best cnc plasma cutter integrates the advantages of high-speed plasma and high-speed plasma Numerical control technology, computer software, hardware technology, plasma cutting technology, precision machinery technology in one of the high-tech.

1. Use the ignition rod. The method is to add a steel plate close to the thickness of the steel plate at the cut-in point, and there is a gap at the close point. The cutting knife should cut from the ignition rod, and the ignition rod will guide the flame of the cutting tool to the bottom of the steel plate so that the burning speed of the steel plate is consistent. Get the best cutting section.

Ignition rods can be replaced by scraps that are cut downward. Small amount methods reduce the distance between the workpiece and the edge of the board, reduce the generation of corner material, and effectively improve the utilization rate of the board. Practical.

2. Use arc feed to increase the length of the appointment line and avoid direct entry points. This method has a better effect and is more widely used in production. Its disadvantage is wasted materials.

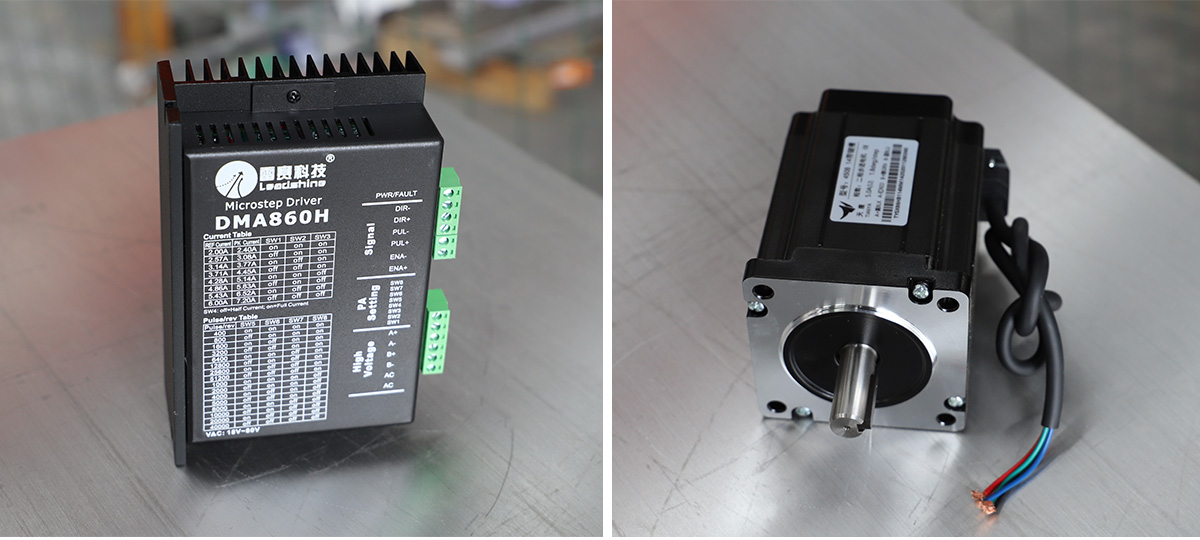

High-end drive system

Features of plasma cutter cnc machine:

This CNC cutting machine adopts thick square tube wholly welding; the machine body adopts shaking preventing technical disposal, with the features of firm, shape retention, and high rigidity.

Reasonable platform design, the flat table adopts 10mm precision process steel plate install on the machine table, and then install precision process cast iron cover to protect the vertical steel, to prevent the steel plate affected by high strength flame. The level difference of whole double-deck platform remains in 0-1.5mm.

Reasonable pitch leaks design, to make the work piece and other fragments slide to the sides of the knife rack, safe and convenient to use.

This machine adopts Starfire control system. StarCAM Software.

The machine adopts Huayuan power source (power 63A/120A/200A) together with high sensitive arc pressure adjuster. Self-adjusting to choose the best distance between plasma head and work piece automatically in order to ensure cutting accuracy

Perfect reasonable design and high immaculate surface's work piece make the machine best choice for different thickness material and heterotypic sheet cutting

Parameters:

Best cnc plasma cutter advantages :

Efficiency

CNC plasma machines are designed to tackle large-scale cutting, manufacturing jobs, and one-off custom fabrication or art project in a fraction of the time it would take to perform with a hand tool. You are able to program and cut diverse shapes on demand, with no pre-heating or cooling required. A CNC plasma machine is truly ready to work at a moment’s notice.

Precision

Because a CNC plasma machine is operated via CNC Control, it is extremely precise. Once the cut is programmed, the torch moves in an exact path set by the computer that is reliable and consistent every time. This leads to unmatched precision on essentially any cut, no matter how complex or refined.

Low cost

CNC plasma machines have been around for a few decades, and while they used to be highly specialized machines, they have become far more accessible and affordable in recent years, with shops ranging from large industry names all the way to sole contractors or hobbyists being able to experience the benefits.

Better results

The results experienced with a CNC plasma tool as compared to metal-against-metal cutting are undeniably far superior. The plasma cut will produce no chips and achieves a consistent edge, with limited error as long as the cut is properly programmed.

Safety

Another benefit of the CNC plasma machine being computer operated is its increased safety due to automation. The cut is set up and completed electronically, removing the need to hold a torch or handle metal during the process. The plasma is safer than most other gas-cutting alternatives.

Easy to use

A CNC plasma machine is easy to use and requires minimal training to learn how to operate effectively. This drastically reduces onboarding costs for shops looking to hire machine operators and also provides increased accessibility for one-man shops looking to add a CNC plasma tool to their arsenal.