Views: 12 Author: Site Editor Publish Time: 2021-11-27 Origin: Site

CNC metal fiber laser cutting machine is a type of CNC machine that uses a fiber laser to cut metal materials with high precision and accuracy. The machine works by directing a high-powered laser beam through a fiber optic cable, which is then focused onto the metal material to be cut.

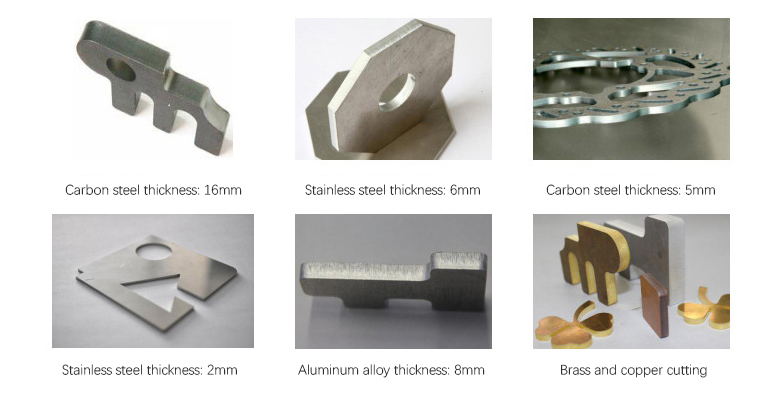

Fiber laser cutting machines for metal are capable of cutting a wide range of metal materials, including steel, aluminum, brass, copper, and others. The machine can be programmed to cut and engrave metal materials in a variety of shapes and sizes, from simple straight lines to complex curves and designs.

Fiber laser cutting machines for metal are commonly used in metal fabrication shops and factories for a variety of applications, such as creating parts for machinery, automotive components, metal signage, and decorative metalwork. They are also used in prototyping and manufacturing for both small and large-scale production.

When choosing a fiber laser cutting machine for metal, it is important to consider factors such as the size of the machine, the power of the laser, the level of automation and precision required, and the software it uses to control the cutting process. It is also important to consider the type and thickness of the metal materials you will be cutting, as this will affect the power and capabilities of the machine.

12000W IPG Fiber Lasers Source

World Famous Brand

laser cutting machine series high power fiber laser of IPG. Powerful cutting ability with stainless steel, aluminum and other metal materials, cutting thickness is up to 40mm.

Long Service Life

The world leading IPG laser has stable performance, the service life can reach 100000 hours, and the overall quality of the equipment can be guaranteed safely.

Stable Cutting Performance

Fiber laser source can produce excellent beam quality, finer cutting lines, higher working efficiency and better machining quality. Fully closed constant temperature working environment makes laser source more effective to ensure the stable operation.

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Optical fiber laser cutting machine is a new type of laser cutting machine developed in recent years.It USES the fiber laser to output the high energy density laser beam and concentrates it on the processing material to achieve the effect of automatic cutting.Mainly used for carbon steel, stainless steel, silicon steel and other metal materials under 25 mm.Therefore, as a new laser cutting machine, compared with CO2 laser cutting machine,

What are the advantages and disadvantages of fiber laser cutting machine?

1. Good beam quality: the smaller the cutting line is, the higher the processing efficiency is and the better the processing quality is;

2. Fast cutting speed: the optical fiber laser cutting machine is twice of the equal power CO2 laser cutting machine;

3. High stability: Wuhan Ruike fiber laser, stable performance, the service life of key components can reach 100000 hours;

4. Electro-optic conversion efficiency is very high.Optical fiber laser cutting machine is about 30%, three times of CO2 laser cutting machine, energy saving and environmental protection;

5. Low operating cost: the power consumption of the whole machine is only 20-30% of that of the same CO2 laser cutting machine;

6. Low maintenance cost: optical fiber transmission, no reflector;Basically free of maintenance, can save a lot of maintenance costs;

7. Simple operation: optical fiber transmission, no need to adjust the optical path;After a simple training can be used, very convenient.

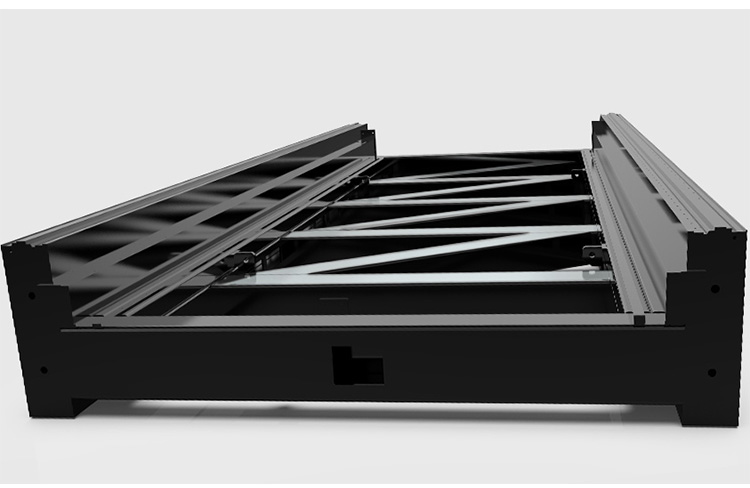

High-load wrap-around hollow bed

The special bed for ultra-high power laser cutting machine is made of high-strength steel. The cutting area is hollow to prevent the machine from overheating and deforming. This bed has the advantages of fatigue resistance and overburn prevention, ensuring the cutting accuracy of the machine bed.

Partition dust removal system

The fan is placed on the top of the protective cover, and the intelligent smoke detection can automatically start and stop the smoke exhaust according to the amount of smoke; the positive wind pressure creates a real smoke-free environment, and at the same time ensures that the operator can observe without obstacles when cutting thick plates.

Auto Focus Laser Head

Lightweight design, fast acceleration, the monitoring data can be read on the mobile terminal or CNC system, autofocus is simple, fast and more precise, distance sensor 0 drift measurement is more accurate, CoolTec cooling technology quickly cools the sheet metal surface temperature, the airtight light path protects against dust falling and protects the lens for continuous monitoring.