Views: 10 Author: Site Editor Publish Time: 2022-02-28 Origin: Site

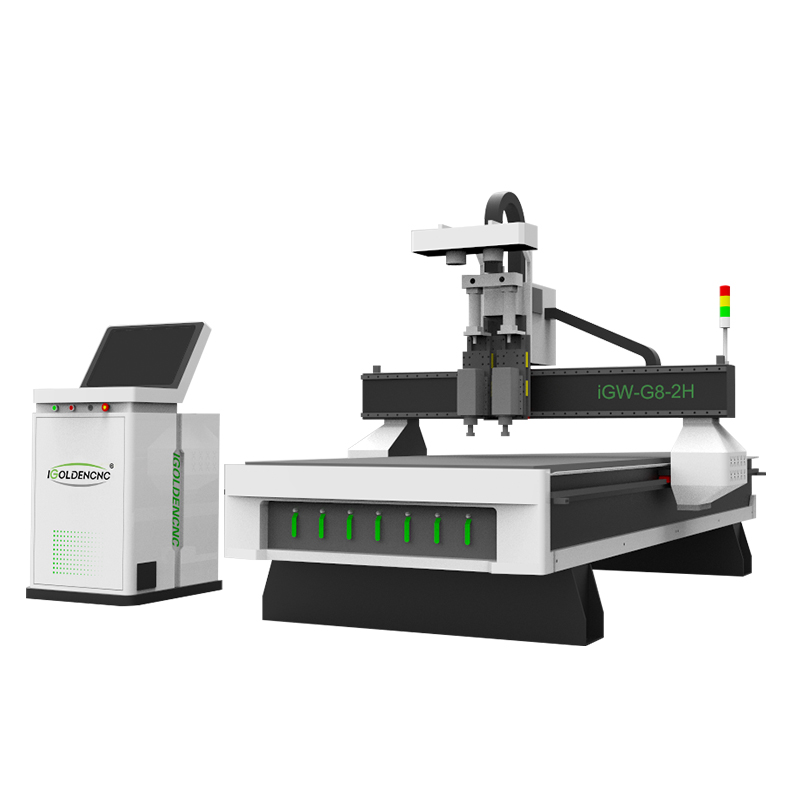

1325 Wood Engraving CNC Router is a type of computer numerical control (CNC) machine that is designed specifically for engraving and cutting wood materials. The "1325" refers to the machine's working area, which measures 1300mm x 2500mm.

This type of CNC router is commonly used in the woodworking industry for creating intricate designs on wood surfaces, such as cabinetry, furniture, and decorative items. The machine uses a spindle motor to rotate a cutting tool, such as a router bit, which can be programmed to move along multiple axes to create a wide range of shapes and designs.

The 1325 Wood Engraving CNC Router is often equipped with a vacuum table to hold the workpiece securely in place during the cutting and engraving process. The machine may also have a dust collection system to remove wood chips and dust from the work area, which is important for maintaining a clean and safe workspace.

In addition to wood materials, the 1325 Wood Engraving CNC Router can also be used to cut and engrave other materials, such as plastics, foam, and non-ferrous metals, depending on the spindle motor and cutting tools used.

We deal in Wood Engraving Cnc Router . We are one of the best supplier of our area.

This 3-axis wood engraving machine has the common advantages of ordinary 3-axis engraving machine, including low procurement and maintenance costs, and you can achieve your processing on non-metallic materials without high procurement costs and maintenance costs. In addition, the operation is relatively simple. Therefore, it is the best choice for your simple processing.

1) The whole machine adopts seamless welding of steel structure, with strong bearing capacity and small deformation. Linear square rail, high precision, wear-resistance and stable operation.

2) Adopt a linear fixed or follow-type automatic tool change system, the tool change time only needs ten seconds, which saves tool change time and improves production efficiency.

3) Professional factory with Mach 3 control system, can provide good after-sales service and technology support

4) File preprocessing function helps users correct errors in processing files in time and is well compatible with processing codes generated by Type3/Artcam/Aspire/Solidworks etc. In the three-dimensional curve prediction algorithm, the broken line is stable, to ensure the speed and accuracy of the curve.

5) Dust collection and adsorption device: The dust collection system can absorb wood chips and debris during the processing process, and maintain the equipment in disguised form to keep the workbench clean; the multi-zone vacuum adsorption table can be used for adsorption of different sizes of plates instead of The mechanical plate fixing in the past has shortened the loading and unloading time of the plate outside of processing.

6) It has the function of breakpoint and continuous engraving after a power failure, and automatic error correction function when returning to the origin, which effectively guarantees the processing accuracy when working for a long time.

1. Accurate carving:

The CNC engraving machine is controlled by the computer, and the computer is used for engraving. The layout of the computer is set to ensure the accuracy and error of each process.

2. Simple operation:

The central main control system of the CNC engraving machine is based on the imaging operating system to terminally issue engraving commands. This requires workers to put the material on the machine tool and then activate the switch.

3. Diverse patterns:

The CNC engraving machine can operate all kinds of complex engraving without difference.

4. Raw material saving:

The engraving machine data is accurate without errors, so it will not cause the loss of raw materials and reduce the cost.

1. The engineers design the wood cutting cnc router according to your needs.

2. The purchasing department carefully select and buy the machine parts.

3. The skilled workers make the machine.

4. The quality control department supervise the whole manufacture process.