Views: 82 Author: Site Editor Publish Time: 2023-01-05 Origin: Site

Linear ATC CNC Router with Auto Tool Changer Description:

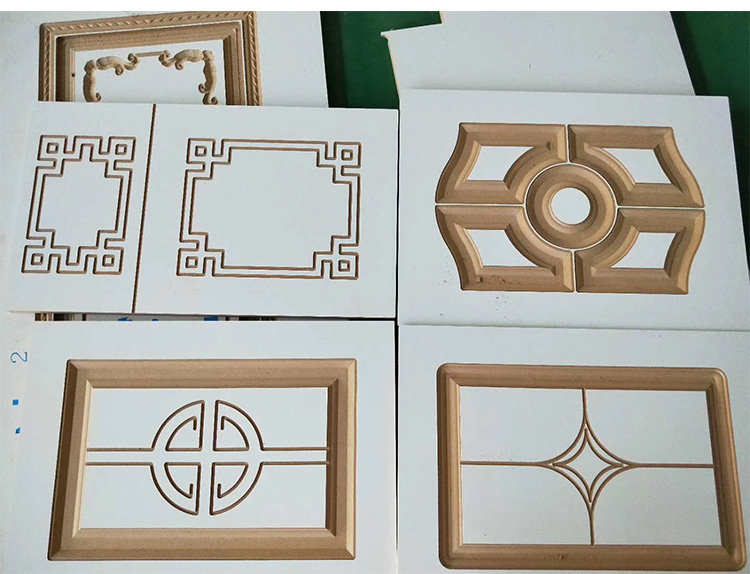

There are two tool change modes for inline tool change and disc tool change. Widely used, including engraving, milling, chamfering, side milling, drilling, cutting, grooving, etc.

From small surface engraving to large organic shapes, this machine will truly allow your creativity to run wild.

Featuring a linear automatic 8-tool changer, this is the most advanced CNC router we offer, capable of machining complex surfaces over the entire surface of the 4' x 8' bed.

The table has four independently controlled vacuum zones to secure your workpieces during cutting operations.

Linear automatic 8-tool changer,This CNC Router is the 3D, 4 axises CNC Router machine, with linear auto tool changer function,can change 8 piece tools once time.

HSD air-cooled spindle motor,

Vacuum table with four independently controlled zones

Tool touch-off pad for quickly setting Z-axis height

Two-stage air vacuum pump (requires separate 3-phase, 220V hardwire connection)

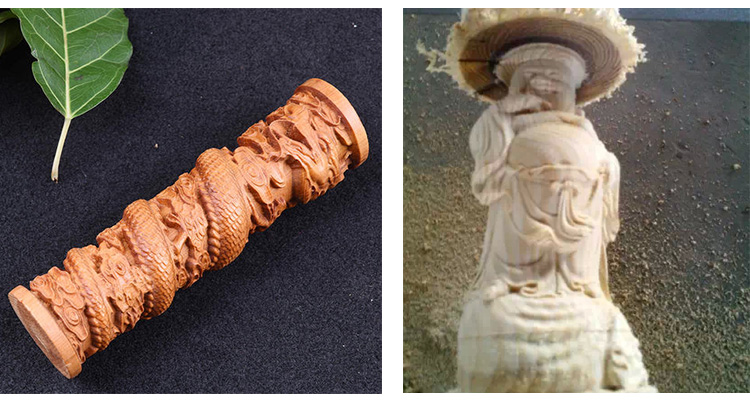

with scanner or designed photo, it can do any 3D engraving and 2D engraving.

Helical rack-and-pinion X- and Y- gantry travel

4th-axis machining capability around Y-axis

CNC router lathe machine (rotary CNC router) is a type of multifunctional CNC machine kit with 4x8 table size for flatbed full sheet cutting, relief carving, and 4th axis for 3D rotary milling. The T-slot vacuum table is used for board cutting, edging, carving, drilling and grooving, and the rotary device for turning, like a lathe machine.

The spindle of the conventional type is unable to rotate. So there are only three axes X, Y, and Z. To see how the 4 axis spindle rotation works, let's move to the next part.

It has four motion axes, namely X, Y, Z, and A axes. The A-axis here refers explicitly to the spindle rotation; it can mill within the range of plus or minus 120 degrees. Besides, we have equipped it with a linear automatic tool changer. (We will dig deeper why this option is essential later) The spindle and motion motor is the world's top brands, HSD and Yaskawa. The CNC controller is also a famous brand-the SYNTEC from Taiwan. 2023 best 4 axis cnc router with automatic tool changer for sale at a reasonable price now!

4 Axis CNC Router is suitable for cutting and engraving 3D workpieces, such as foam molds, wood and stone sculpture and statues except for the basic applications. In addition, it can also drill side holes or make side grooves or slots on the side of wood panels. The 4 axis ATC CNC router has an extensive use in sculpture and statue making, mold, furniture, decoration, craft, advertising and other fields.

| Model No. | 1325 ATC CNC Router with rotary axis |

| Type | Automatic Tool Changer 4 Axis CNC Router |

| Max.Simultaneous Axis Qty | Four |

| Machine Base | Heavy-duty, finish by CNC machining center, not a simple handjob |

| Working Bed | PVC Vacuum with embedded T-slot |

| Bed Size | 1300x2500mm (4'x8') |

| Flatbed Clamping | By vac-sorb or clamps |

| X-Axis Stroke | 1300mm [48"] |

| Y-Axis Stroke | 2500mm [96"] |

| Z-Axis Stroke | 300mm [11.8"] |

| A-Axis Stroke | ±120° |

| Electric Spindle | Italian HSD auto tool change spindle, 9.0Kw, 24000rpm, ISO30 tool holder or China 9.0Kw ATC Spindle |

| Collet Size | ER32 |

| Acceptable Tool Diameter | 3.175 ~ 20mm (1/8 "~ 3/4") |

| Tool Bank | Linear type automatic tool changer with 8 positions |

| Electronic Cabinet | Individual, with cooling heat exchanger |

| Tool Length Sensor | Included |

| Position Accuracy | 0.10mm/300mm |

| Reposition Accuracy | 0.10mm/300mm |

| Motion Drive | Yaskawa servo 850 watts - 4 SETS, 400 watts - 1 SET |

| Driver | Yaskawa |

| Fast Travel Speed | 60,000mm/min |

| Max. Cutting Speed | 45,000mm/min |

| CNC Controller | SYNTEC 4 Axis Control |

| X-Axis Transmission | Helical rack and pinion, planetary gearcase |

| Y-Axis Transmission | Helical rack and pinion, planetary gearcase |

| Z-Axis Transmission | Rolling ballscrew, 25mm, pitch 10mm |

| A-Axis Transmission | Harmonic gearcase |

| X Linear Guides | Square type, 25mm |

| Y Linear Guides | Square type, 25mm |

| Z Linear Guides | Square type, 25mm |

| Communication Command | G code |

| Compatible Programming Software | ArtCAM, Aspire, PowerMILL, UG |

| Other Electronics | Schneider, Omron, CHNT |

| Cables | High softness shielding cables for the whole machine |

| Lubrication System | Volumetric Central lubricating, auto type |

| Vacuum Pump | Water-ring 5.5kw or Dry-type 5.5kw |

| Working Power | AC380V/50Hz, 3Ph (or AC220V/60Hz, 3Ph) |

| Max. Power Consumption | 25KW |

| Net Weight | 1,400KGS |

| Gross Weight | 1,500KGS |

| Package Way | Plywood Case |

| Package Dimension | 3360*2250*2230mm (16.80CBM Approx.) |

| Option Devices | 1) Movable adsorption blocks 2)Dust collector |

A: Yes, you'll need a forklift as the CNC is 1500 or 1950KGS.

A: You will get a perfect solution that gets both software programming and hardware operation involved from us. EagleTec CNC not only sells cnc machines but more importantly, we will guide you to put your device into production step by step. Technical support is also a crucial part of the product value. About this, please refer to our testimonials.

A: There are two commonly used software: PowerMILL and UG. If your design file is ***.stl, we should program the toolpath in PowerMILL; we can use other formats to use UG.

A: We put your order into production on receipt of the down payment, and the lead time is 20 business days.

A: It's It's a 12-months warranty since the departure. Under warranty, you'll enjoy free replacement for any broken parts except Vulnerable parts. After that, we provide you with constant free online support; for spare parts replacement, it will be charged based on materials cost.

content is empty!