Views: 26 Author: Site Editor Publish Time: 2022-11-28 Origin: Site

iGP-3A is a 4x8 CNC plasma table machine. The actual cutting size is 1300x2500mm (4x8 feet); So, it can cut anywhere on the steel plate in the range of 4x8 feet (1300x2500mm). The plasma cutter equipped is 200A - Brand Huayuan LGK-200IGBT. Accordingly, its maximum quality cutting thickness can be up to 40 mm for all kinds of sheet metal includes carbon steel, stainless steel, aluminum, iron, copper, and brass. The 4x8 cnc plasma table for sale at a good price now.

The Igolden iGP-3A is a growing business’s ideal 4x8 CNC plasma cutting table. It’s engineered as an all-in-one CNC machine that comes fully assembled and ready to take on the first job within minutes of uncrating. The larger cutting area allows you to avoid additional shearing fees from your steel supplier.

Plasma Cutting Machine Parameter Configuration

| Description | Parameters |

|---|---|

| Working area | 1300x2500mm |

| Machine Body | Thickened Square Tube Welding Body |

| Worktable | Sawtooth |

| Reducer | Japan SHIMPO |

| Control System | STARFIRE with THC |

| Plasma Power | HUAYUAN |

| Lubrication | Automatic |

| Transmission | X,Y-helical rack pinion, Z ball screw |

| Drive system | Japan servo motor and drivers |

| Power | 63A/ 100A/120A/160A/200A |

| Cutting Torch Path | ≤200mm |

| Positioning Accuracy | 0.2mm |

| X, Y Axis Resolution | 0.1mm |

| Working Voltage | 380V/50Hz |

● Heavy load construction

● Actual cutting size 4' x 8' (1300x2500mm)

● Includes 200amp plasma cutter, brand HUAYUAN

● STARFIRE cnc plasma table controller

● Automatic torch height controller

● Linear guideway 20mm

● Step drives

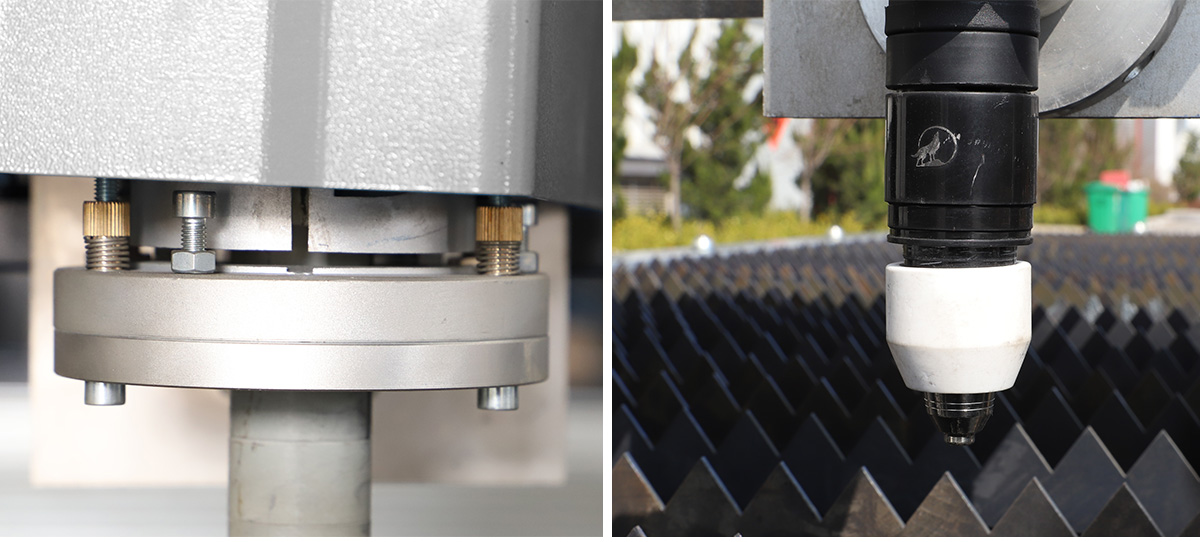

Sawtooth worktable

4x8 CNC Plasma Cutting Machine Application

Advertising industry: Advertising signs, logo making, decorative products, production of advertising and a variety of metal materials.

Mold Industry: Engraving metal molds made of copper, aluminum, iron and so on.

Metal industry: For steel, Carbon Steel, Stainless steel, alloy steel, spring steel, copper plate, aluminium plate, gold, silver, Titanium and other metal plate and tube.

The beam uses light structural design,with good rigidity structure, light deadweight .

The gantry structure, Y axis used dual-motor dual-driven system,X,Y,Z axis all use dual-straight rail that make the machine driving smoothly with high-precision.

Aiming at cutting three dimension LED character, trough metal panels and floor cutting, the accuracy can reach good indicators.If it equipped with United States HYPERTHERM plasma source the machine can reach threshold.

Equipped with other advertise equipment (blister/engraving machine) . Improve the efficiency of several times.

Cutting mouth is small, tidy,and avoid a second dressing processing.

It can apply to iron sheet, the aluminium sheet, the galvanized sheet, hundred steel plates , metal plates.

The numerical control system disposes high, the automatic striking arc, the performance is stable.

Support Wentai, Astronautics Haire, ARTCAM softwares, Type3 produce standard G code way document,also can change software to read AUTO CAD softwares produce DXF form documents.

Plasma cutter comes from welder, which is a unique type of plasma welding system. It uses plasma to fuse two metals together. By increasing plasma arc discharge, plasma welding system can be transformed into plasma cutting system. At this stage, most of the thermal cutting and welding businesses are from plasma. Among them, plasma cutting machine has developed portable, cantilever, gantry, desktop, tube cutting machine and other forms of cutting equipment, while plasma welder is divided into manual welding machine and robotic welding machine. Plasma cutter uses a plasma arc to generate high temperature to melt the material to be cut. At the same time, it uses compressed gas to blow away the material to be cut into slits to complete the final cutting projects. It has the advantages of good cut quality, narrow cut width, high precision, fast cutting, safety, and cleanliness.

Plasma cutter comes from welder, which is a unique type of plasma welding system. It uses plasma to fuse two metals together. By increasing plasma arc discharge, plasma welding system can be transformed into plasma cutting system. At this stage, most of the thermal cutting and welding businesses are from plasma. Among them, plasma cutting machine has developed portable, cantilever, gantry, desktop, tube cutting machine and other forms of cutting equipment, while plasma welder is divided into manual welding machine and robotic welding machine. Plasma cutter uses a plasma arc to generate high temperature to melt the material to be cut. At the same time, it uses compressed gas to blow away the material to be cut into slits to complete the final cutting projects. It has the advantages of good cut quality, narrow cut width, high precision, fast cutting, safety, and cleanliness.

content is empty!