Views: 58 Author: Site Editor Publish Time: 2022-12-28 Origin: Site

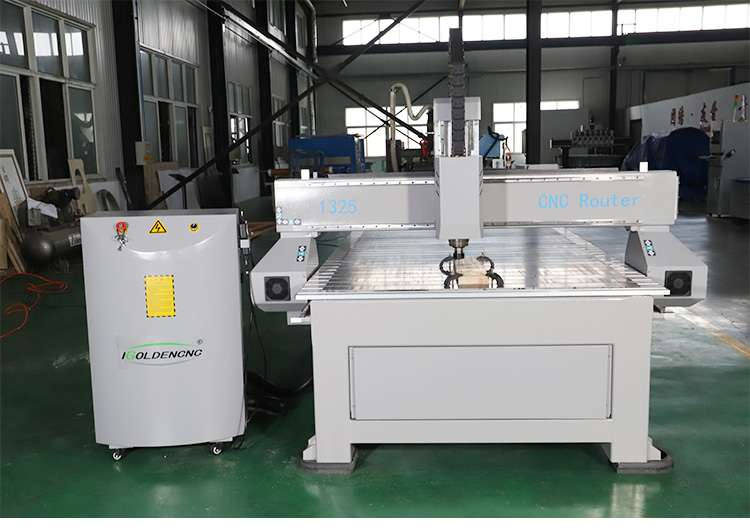

The woodworking carving CNC machine has become one of the most popular CNC machines in the woodworking industry. Because this kind of machine can process a variety of products, such as small wooden products, wooden furniture, wooden artwork and so on. And The wood carving machine has many types of machines for buyers to choose from.

And this kind of machine can be equipped with a variety of CNC milling cutters, so that the machine can achieve a variety of functions, such as engraving, cutting, grooving, lettering, drilling and so on. This wood carving machine is mainly used to process wood, but this machine can also process other materials, such as rubber, stone, resin, plastic, acrylic, foam, soft metal, etc.

The Best CNC Machines and Routers for Woodworking– Buying Guide

What makes a great CNC router for woodworking, and which is the best CNC router kit for different skill levels? To find out more, and before splurging on a CNC machine, review the buying guide below to better understand the additional features commonly found on these tools.

Processor

The most commonly purchased tool for its price and precision, the three axes (X-axis, Y-axis, and Z-axis) CNC machine includes multiple spindle speeds, mini CNCs, and YZ machines. While in use, the spindle stays on the same course making it a good student or beginner CNC unit.

4-Axis

A 4-axis router has the three axes plus an A-axis, which allows the spindle to move left and right to process three surfaces concurrently to achieve plane and 3D engraving. This tool is ideal for carving wood or even soft metals into complex 3D pieces and patterns.

Rotary axis

Rotary axis CNC routers have a rotary spindle tool that allows them to process four surfaces simultaneously. This is especially useful for cylindrical projects that, when finished, will be in 3D, like intricate furniture accents or decorative wooden statues.

Motor

There are two types of motors on CNC tools—servo and stepper motors.

Servo motor

The servo motor tolerates high speeds, can cut wood precisely and resists overload for a longer-lasting tool. It’s also quieter and more steady and is ideal for intricate patterns. The faster the speed of the motor, the more productive the CNC tool will be.

Stepper motor

A stepper motor is the more affordable price of the two and is fine for basic plane engraving. Stepper motors are easy to control, dependable, and precise. They are also suitable for the average woodworking project.

Drive

CNC router machines have two different transmission drive systems—a screw drive and a rack drive.

Screw drive

The screw drive is the more basic of the two, with slower speeds and short tool life. If not installed properly, the screw drive can become loose and constantly need tightening. This type of drive is used primarily for smaller wood carving projects.

Rack drive

The rack drive provides a much more accurate transmission and can handle larger projects and multiple configurations. This drive is faster, lasts longer, and is more expensive. This type of drive can be used on a laser module for effective engraving depth.

Spindle

Spindles can have a water cooling system or be air-cooled.

Air-cooled spindle

An air-cooled spindle simply uses a fan to cool the spindle down and is more economical, easier to maintain, and user-friendly.

Water-cooled spindle

A water-cooled system uses water to cool the spindle down when the spindle speed is too fast. It’s quieter than a fan-cooling system, generally lasts longer, and is more precise.

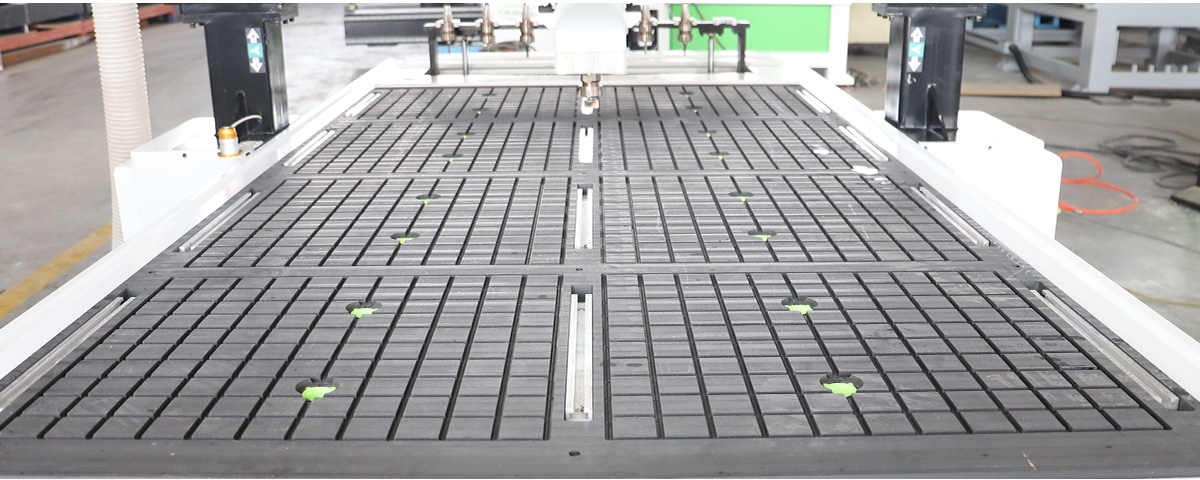

Table Size and Bed

Router tables come with two types of tables, an aluminum table, and a vacuum table.

Aluminum tables

The aluminum table requires pieces to be clamped to the table and is excellent for cylindrical or other oddly-shaped projects.

Vacuum tables

A vacuum table vacuums the part directly to the table without clamps. This allows for more precise engraving since there is less shaking while in use.

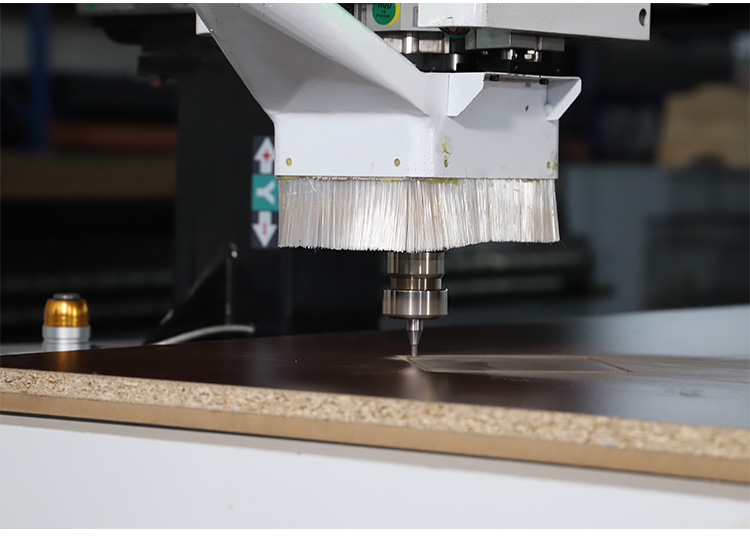

Dust Collection

A dust collection system is a great perk to have on one of these machines when it comes time for cleanup. Some CNC machines have a dust port that allows the device to collect dust while carving.

1. Machine body design with high strength and double dirving motors of Y axis, which have more reasonable design, fast processing speed, easy-operated maintanance and low fault rate.

2. Advanced CNC processing system has powerful functions and humanized operation, as well as can receive data through U disk or network.

3. Imported servo drivers and motors have characteristics such as powerful strength, fast processing speed, stable operation and extreme low noises.

4. High power spindles have constant power, low noises and superstrong cutting force, which improve working efficiency greatly.

5. Imported and high precisive linear guideways have features such as stable operation, high precision and steady support, which prolong service life of machines.

6. Z axis adopts imported ball screw with industrial level can positioning accurately and make processing effects more perfect.

content is empty!