Views: 11 Author: Site Editor Publish Time: 2021-09-02 Origin: Site

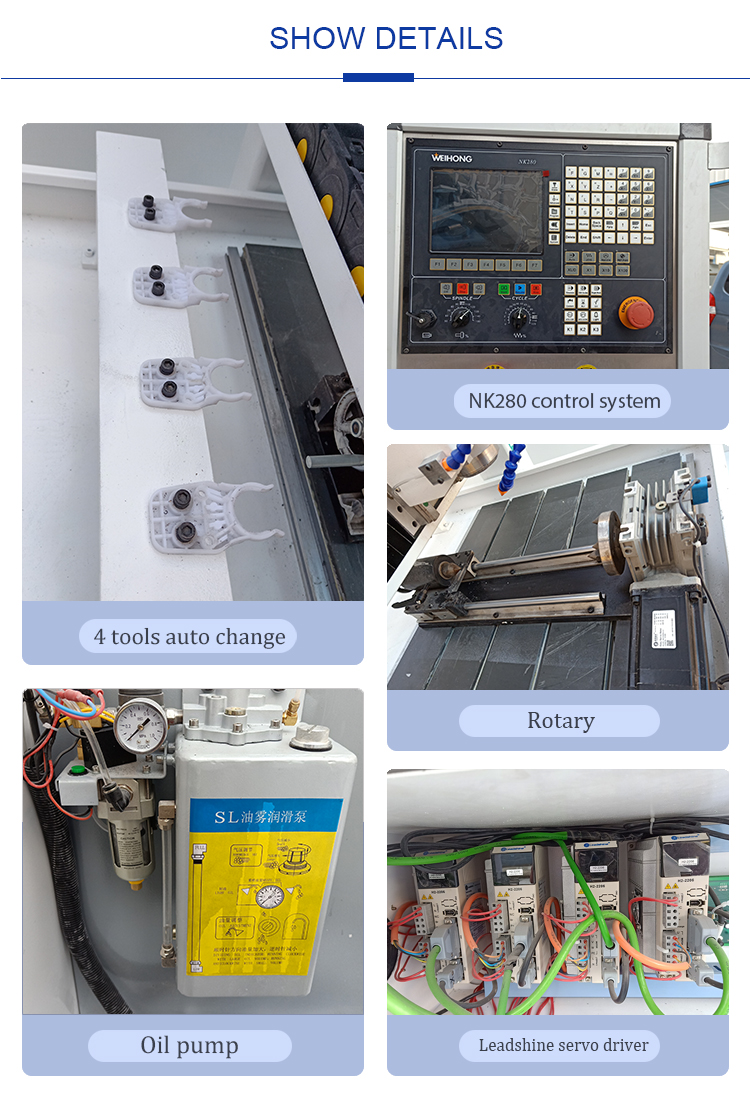

This CNC milling machine is suitable for the precision machining of complicated parts such as: plate type, disc type, shell type, mould and etc. This CNC milling machine has parts such as automatic tool changer CNC system, fully enclosed protection cover, automatic lubricating system, cooling system, drawer type manual chip conveyor devices. Working like milling, boring, drilling, reaming, cutting, tapping can be done in one process. The fourth axis can be added as an option to complete the working if needed.

1. Taiwan TBI ball screw, make the precision higher,

2. NC studio control system, connected with computer, easy to operate,

3. Imported HIWIN guide rails, make the machine working more smooth and higher precision.

4. 2200W water cooling spindle with 24000RPM, large Torque,

5. Oil cooling system, professional for working on metal.

CNC milling machine Application:

1. Wood furniture industry

Doors; Cabinets; Tables; Chairs.

Wave plate, fine pattern, antique furniture, wooden door, screen, craft sash, composite gates, cupboard doors, interior doors, sofa legs, headboards and so on.

2. Advertising industry

Signage; Logo; Badges; Display board; Meeting sign board; Billboard

Advertising filed, sign making, acrylic engraving and cutting, crystal word making, blaster molding, and other advertising materials derivatives making.

3. Die industry

A sculpture of copper, aluminum, iron and other metal molds, as well as artificial marble, sand , plastic sheeting, PVC pipe, and other non-metallic mold.

4. Artwork and Decoration

wood crafts; gift box; jewelry box

5. Others

Relief sculpture and 3D engraving and Cylindrical object.

CNC Machine Center, Parameter Configuration

Description | Parameters |

|---|---|

Working area | 600*600*200mm |

Transmission | Germany ball screw |

Table structure | T Slot |

Spindle power | 2.2KW |

Spindle speed | 24000rpm/min |

Travelling speed | 30m/min |

Working speed | 15m/min |

Working Delicacy | 0.01mm |

| Driving Moto | Leadshine servo motor |

Controller | NK280 control system |

Command Code | G Code*.u00*.mmg*.plt |

Voltage | AC380V/50HZ |

Software | Artcam/Type3,other CAD/CAM |