Views: 36 Author: Site Editor Publish Time: 2022-12-08 Origin: Site

As the furniture CNC machine becomes increasingly mature, many factories intend to choose furniture CNC machine to realize mass production. Furniture makers can also choose different furniture making machines to form an automated furniture production line.

Nowadays, panel furniture has gained more popularity due to its simple style, easy assembly, and favorable price. To meet mass production requirements, many panel furniture factories choose the furniture CNC machine. This article will introduce to you the furniture making machines used in three different production lines. Besides, these machines can be combined freely according to your specific demands.

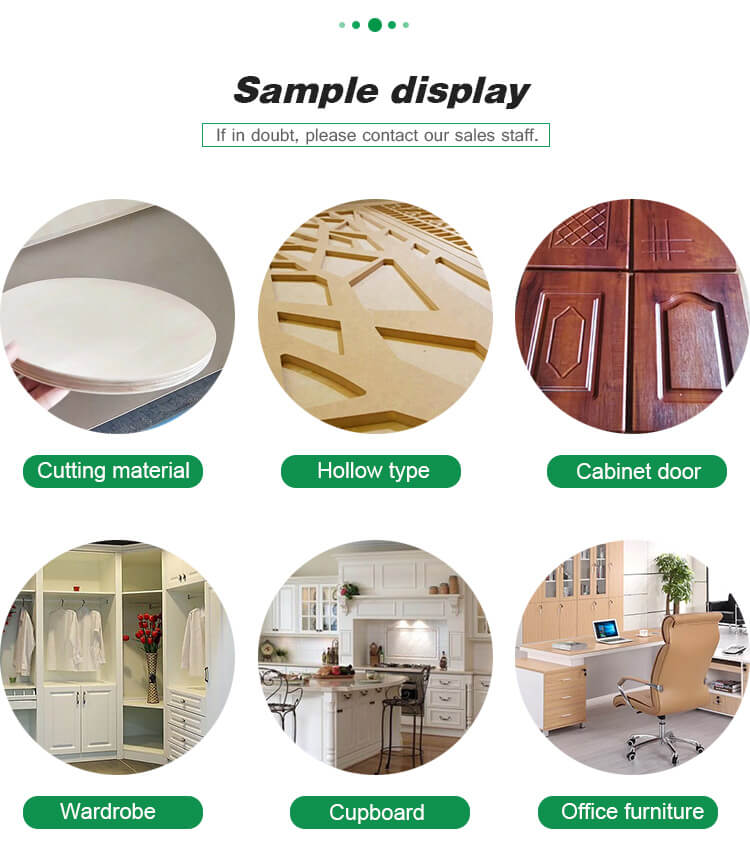

Furniture CNC equipment can easily turn 2D “sketches” into figurative furniture. It creates greater convenience and more possibilities for manufacturing panel furniture. Moreover, multiple CNC furniture machines with different functions, such as CNC drilling machines, edge banding machines, polishing machines, panel saws, etc., can form the furniture production line. And the iGOLDENCNC panel furniture line has higher efficiency and automation, which can easily design custom furniture. Here, we will look at some amazing and practical furniture CNC designs for sale right now.

CNC offers standard & custom-made industrial wood furniture machines, wood cabinet machines, wood door making machines & delivery from China to your place anywhere.

Furniture CNC machine in the entry-level cabinet production line As mentioned above, the production process of the cabinet is relatively simple, mainly including cutting, sealing, and drilling. Therefore, the cabinet CNC machine used in the cabinet production line mainly includes three types, CNC cutting machine, edge banding machine, and side hole drilling machine.

Our furniture cnc machine includes: Furniture CNC Router Machine, Wood CNC Drilling Machine, Horizontal Panel Beam Saw, Edge Banding Machine, etc. Wood door machines are good at making wood doors such as exterior doors, interior doors, flush doors, HDF molded doors, membrane doors, slab doors, etc.

The furniture production lines mentioned above are not fixed. You can increase or decrease the types or configurations of furniture CNC machine according to your own processing needs. By combining different furniture making machines, you can form a furniture production line that is most suitable for your business. This maximizes efficiency, reduces labor, and brings more benefits.

If you have a sufficient budget, you can consider the smart furniture production line to start your business. The smart furniture production line aims to maximize work efficiency by using the least human labor. Generally, the furniture CNC machine used in the production line is highly automated and intelligent. Except for the furniture CNC machine, the furniture production line also includes robot arms, conveyor platforms, gantry, loading and unloading platforms, etc.

Furthermore, the smart furniture production line has certain requirements in the factory area. You must have enough space to put all the furniture making machines and connect them into a complete line. In addition, the whole smart furniture production line is very expensive. Therefore, the smart production line solution is more suitable for large-sized furniture factories.

content is empty!