Views: 36 Author: Site Editor Publish Time: 2022-02-14 Origin: Site

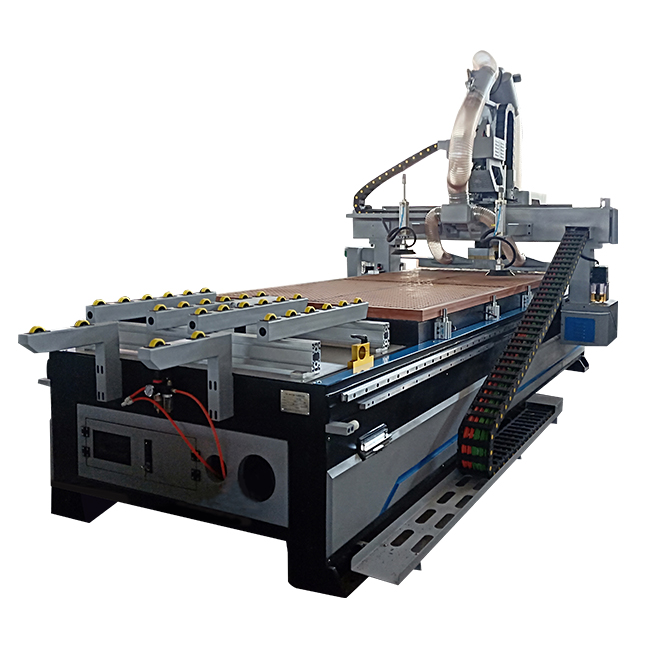

CNC nesting machine furniture with loading and unloading system is the intelligent furniture production line. ICM brand computer controlled nesting CNC router machine center is specially designed for panel furniture, office furniture, cabinets and other furniture production. With the help of the CAD/CAM and controlling system for process path optimization, model optimal layout, control the drilling, cutting and side slotting process, automatic labelling, the cnc nesting machine furniture is composed of many processes like optimal layout designer, intelligent cutting system, automatic labelling system, automatic loading, vertical drilling, grooving and cutting, automatic unloading, edge bonding, barcode scanning, automatic process selection and side slotting, etc.

As a guaranteed cnc nesting machine furniture and manufacturer, IGOLDENCNC provides all kinds of best CNC nesting machines for sale to suit your needs. IGOLDENCNC 's nesting CNC machines adopt genuine CNC nesting software and CNC nesting system, high quality original nesting CNC machine kits, bits, parts and tools. IGOLDENCNC offers cost price for your CNC nesting machining plans without any intermediate. You will get the best nesting CNC machines at an affordable price from us. STYLECNC also offers smart CNC nesting solutions, 24/7 one-to-one free service and support, which is available free.

The benefits of nesting

Nesting provides critical advantages for CNC work and can have a considerable impact on a project’s overall profitability. It serves to:

Increase productivity

Nesting reduces the number of times you need to set the material and machine by performing more cuts on fewer pieces of material. It also minimizes the travel distance required of your CNC cutter and can allow different parts to share cut lines. After all – you only make money when the machine is cutting.

The automated capability provided by nesting software also means the nesting process is extremely efficient and accurate. These factors all contribute to the outstanding productivity benefits of nesting.

Minimize waste

Utilizing as much of the sheet for cut parts as possible minimizes the portion of it that will ultimately go to waste. This also has a positive impact on overall revenue, as if you’re using less material and discarding less waste, you also don’t have to purchase as much material in the first place and are spending less on operating costs, etc.

CNC router vs cnc nesting machine furniture

As mentioned above, both the CNC router machine and the nesting CNC machine are capable for woodworking work. And both can cut, engrave, drill, mill grooves, etc. We often say that the CNC nesting machine is an upgraded model of the wood router machine. So what are the similarities and differences between these two machines? Similarities

Similar appearance and configurations. Both the wood CNC router and the nesting CNC machine mainly consist of mechanical parts and electrical parts. The mechanical parts include frame, worktable, gantry, etc. The electrical parts mainly include motor, driver, inverter, controller, spindle, control cabinet etc. So these two types of machines possess similar appearance.

Similar functions and applications. Both the CNC wood router and the nesting CNC machine are capable for wood working and can cut, engrave, mill, drill and groove various wood materials. These two types of machines have wide applications in furniture industry. They are able to make panel furniture, cabinets, cabinet doors, doors, office furniture and customized furniture etc. Similar with the multi-process or ATC CNC wood router, the nesting CNC machine also has multi-process or automatic tool charger models. Therefore, both the CNC engraving machine and the CNC nesting router can achieve multiple processes simultaneously without frequent showdown for changing tools manually. This greatly saves manpower, reduces the non-production time and increases processing efficiency.

Similar operations. The CNC router machine and the CNC nesting machine are numerical controlled machines and both of them have high automation level. They use corresponding computer software to make layouts and designs and the machines complete the subsequent processes automatically. No additional human intervention is needed. Both these two machines can significantly reduce human cost, improve production efficiency and reduce material loss.

Similar performance. Both the CNC wood carving machine and the nesting machine have performance of high precision, high efficiency and high production. During the course of processing, the operators are able to see the whole process to the maximum extent. And at the same time the machine provides protection and reliable safety features for the operators.

CNC nesting machine furniture features:

SPINDLE

The Techno Venture Cabinet Nesting Series Machine comes standard with a 12 HP HSD high frequency automatic tool changer. This precision spindle requires no regular maintenance, uses industry standard ER collets and ISO 30 tool holders, has fully programmable speeds from 6000 to 24000 RPM.

TOOLING

The Venture Cabinet Nesting Series machine comes standard with a 8-tool rotary carousel mounted to the X-axis beam. This provides faster tool changes during the cutting process.

DRILL BANK

The Venture Cabinet Nesting Series includes a 9-Spindle Drill Bank. All nine spindles are on 32mm centers and are fully programmable for individual or gang drilling. The unit is 3HP “L” shaped drill pattern

Details: Spacing 32mm

Number of vertical drills = 5+4 (5)in X & Y, center is shared

BASE FRAME

The Venture Cabinet Nesting Machine base frame is fabricated from heavy-duty tubular steel that is welded, precision machined and stress relieved so that the foundation remains true and steady over the operational life of the machine.

VACUUM SHROUD

The Venture Cabinet Nesting Machine includes a pneumatically operated vacuum hood that has concentrated air flow at the spindle thus efficiently cleaning up the dust and debris as it is routed.

VACUUM TABLE

The Techno Venture Cabinet Nesting Series Machine includes a double layer high flow vacuum table

TOOL CALIBRATION

Automatic tool calibration pad is designed for easy and accurate recording of tool length off-sets

DRIVE TRAIN ASSEMBLY

The Venture Cabinet Nesting Machine uses precision helical gear racks on the X and Y axes. The mounting of the rack is inverted to help keep dust and debris from building up on the drive system, this assures smooth motion and long term reliability. The precision gearbox is directly coupled to the Servo motor and pinion. This eliminates belt stretch inaccuracies assuring high-speed machining while the system positions the spindle accurately

Manual Pulse Generator (MPG)

The MPG allows the operator to move around the machine, making for easy setup

GANTRY UPRIGHTS

The Gantry uprights are cast iron with heavy duty gussets formed into the casting. Each support is machined for housing the various drive assemblies including motors, bearings, belts, and wiring harnesses.

TOOL CLAMP HOLDER

The Venture Cabinet Nesting Machine comes equipped with a tool holder clamp fixture, providing a much easier way of inserting and tightening the CNC router bits into your tool holder. This method is safer and easier than using the common procedure of tightening the collet nut with two wrenches while the tool holder is still in the spindle.

DRIVE MOTORS

The Venture Cabinet Nesting Machine utilizes AC Servo motors powered by Yaskowa drives. These motors require no regular maintenance — therefore, reducing any maintenance downtime.

Controller

Techno CNC’s Venture Cabinet Nesting Machine Windows-Based G-Code Osai Interface is included with each machine and is an indispensable tool in any CNC Router application. Its open architectural design accepts G-Code files from any industry standard CAD/CAM software package, and can operate using inch or metric units and is highly customizable to better suite your needs. Customers that are new to automation find the Techno CNC Interface easy to learn and operate. Most are up and running in less than one day of training. They find the intuitive design and functions easy to use and remember. The most fundamental controls and displays are all visible on the main page. Customers soon discover that just because the Techno CNC Interface is easy to use, it does not mean that it is not a comprehensive CNC program

ELECTRONICS

All the electrical components are housed and wired in a doubled-doored Nema 4 electrical enclosure. This allows for easy access and service when needed. All wiring is tagged so that when service is required, the customer can easily navigate the cabinet. In addition, the cabinet serves as a work bench for the tools required. tool changer. This precision spindle requires no maintenance, uses industry standard ER collets and ISO 30 tool holders, has fully programmable speeds from 6000 to 24000 RPM, and comes complete with a pneumatically retractable vacuum hood.

PUSHER/SWEEPER

Increase production workflow with Techno’s Venture nesting machine equipped with pusher / sweeper. Our pusher/sweeper pushes the cut material off the bed of the machine and cleans the dust and debris at the same time. Optimal for quick and easy clean up for dusty surfaces. *Optional*