Views: 15 Author: Site Editor Publish Time: 2021-09-28 Origin: Site

EPS Foam CNC Machine adopt integrated casting machine body by well heat treated, which makes machine more stable, rigid, endurable. Adopting Imported high-precision ball screw and Taiwan HIWIN linear square rails, which ensure the machining precision. Especially with a wider travel distance, which is designed for large scale production and suitable for EPS, casting wood mold, engineering plastics and other non-metal material mold.

1) Cast iron high precision machining table, which is heavier and smaller deformation than steel table. Furthermore, it makes machine more smoothly running.

2) Body construction is adopt thick wall steel tube; Beam and support legs are internally ribbed in order to stiffen the assembly; processed by tempering to reduce residual stress.

3) Four-row imported ball bearing, widening linear guide rail, self-lubricating sliding block. When engraving, equal force in all directions, to ensure the accuracy and strength.

4) All the foundational plane is milled by the 5 axis gantry machining center from our factory; make sure the good accuracy from beginning.

5) The linear guide and rack is detected by horizontal detector, to ensure long-term stability of the foam milling machine. Laser interferometer path revises the machining accuracy.

6) The Z-axis has a dual pneumatic counter-balance cylinder to allow very fast and accurate Z-axis positioning.

7) Dust-proof design on X an Y, ensure that the linear guide and rack is clean.

8) Air conditioner on electronic cabinet regulates the temperature inside, maintain the stability of electronic components and extend their life-time.

9) France MOTOVARIO high torque helical planetary gear ensures stable operation with high torque output.

Advantages of EPS Foam CNC Machine

*easy to learn and operate

*TBI ball screw transmisson with high efficiency

*Adopt all English language system and software

*without noise when processing materials

EPS Foam CNC Machine Applicable materials: Polyfoam, poly foam, styrofoam, polyurethane foam, wood, EPS and non-metallic materials.

EPS Foam CNC Machine Applicable industry:

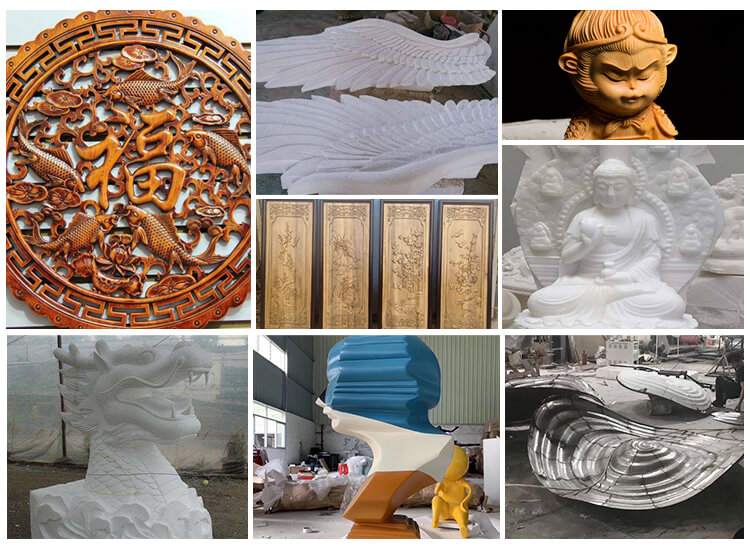

Mould industries: sculpture various large non-metallic mold can be particularly suitable for any kind of Foam (EPS) mould, wooden ship model, wooden model aviation and other wooden mould.

Musical instrument industry: Engrave 3D large instruments and shaping.

EPS Foam CNC Machine Processing effect: It can manufacture the following effects: engraving, cutting, milling, drilling, relief, shadow and so on.

cope of Application