Views: 10 Author: Site Editor Publish Time: 2021-11-27 Origin: Site

The cnc router nesting machine is all steel construction providing the rigid foundation required for ultra-smooth routing results. The cnc router nesting machine includes a 12HP HSD automatic tool changer with 8-position rotary carousel, 9-spindle drill bank, both spindles incorporate pneumatically operated dust collection hoods that concentrate air flow at the cutter, which provides optimal dust collection performance. The multi-zone double layer high flow vacuum table is constructed from very hard Phenolic, which is very stable material, and holds tight tolerances for precision depth cutting, connected to a 10HP Rotary vane vacuum pump (twin pack optional) which has very quiet operation (82db). For easy sheet alignment (3) material pop-up pins are included and precisely placed to handle and align various size materials. The Venture cabinet nesting machine is powered by brushless AC Servo digital motors and drives and is powered by an industrial Osai PC based industrial controller that is easy to use and learn.

Perfect function, automatic feeding, a vertical hole, slotting, cutting, engraving, and milling.

Furniture customized production, mass production come true at one time

Improve production ability, save production cost

Get rid of traditional technology dependence on technical workers.

Whole monitor and control in the whole production

Optional with 5+4 vertical row drill package+tool changing spindle, to meet the various production processes.

Time-saving, labor-saving, material saving. Banned the traditional CAD drawing staff, demolition of a single master, the opening of the material master, efficient and open system, automatic layout optimization to maximize the material utilization.

Automatic coding, automatic loading, blanking, topside drilling, grooving, and cutting.

Total mechanism!

Stop mistakes enhance output

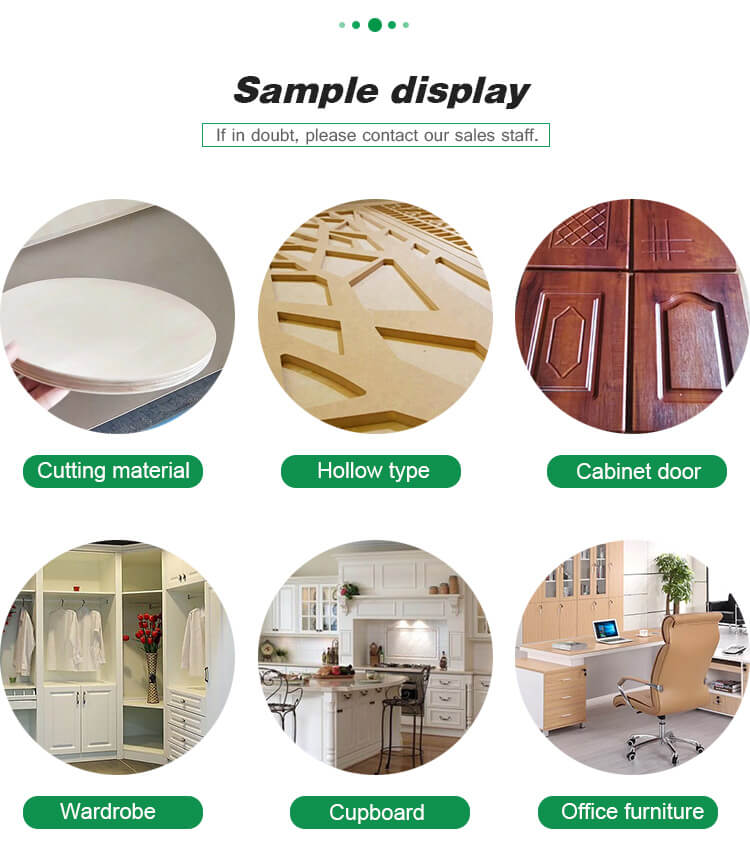

cnc router nesting application:

* Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

* The wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

* Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti-Bate board, epoxy resin, ABS, PP, PE, PEHD and other carbon mixed compounds.

* Decorate industry: Acrylic, PVC,MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

NEW 1325/1530 woodworking cnc atc machine linear type atc tool changer cnc router with 12/16 pcs tools atc nesting machine 2040

Working Area | 1300*2500*300mm |

Machine structure | G6 bed column |

Spindle | HQD 9KW air cooling Automatic tool change+9 holes vertical drilling |

Spindle Speed | 0-18000 rpm |

Inverter | FULING |

Guide rail | PEK |

Reducer | Taiwan SHIMPO |

Working table | Double vacuum suction table |

Control system | Taiwan LNC |

Vacuum pump | 7.5KW water vacuum pump |

Max idle speed | 50000mm/min |

Max engraving speed | 20000mm/min |

Voltage | AC 380V-50HZ |

Weight | 2500KG |

Working Area | 1300*2500*300mm |

Machine structure | G6 bed column |

Spindle | HQD 9KW air cooling Automatic tool change+9 holes vertical drilling |

Spindle Speed | 0-18000 rpm |

Inverter | FULING |

Guide rail | PEK |

Reducer | Taiwan SHIMPO |

Working table | Double vacuum suction table |

Control system | Taiwan LNC |

Vacuum pump | 7.5KW water vacuum pump |

Max idle speed | 50000mm/min |

Max engraving speed | 20000mm/min |

Voltage | AC 380V-50HZ |

Weight | 2500KG |