Views: 15 Author: igoldenCNC Publish Time: 2022-12-20 Origin: Site

Common cnc wood router include ATC wood CNC router, 4 axis wood CNC router, edge banding machine,wood CNC nesting machine, six-sided drilling, cnc drilling machine, etc.

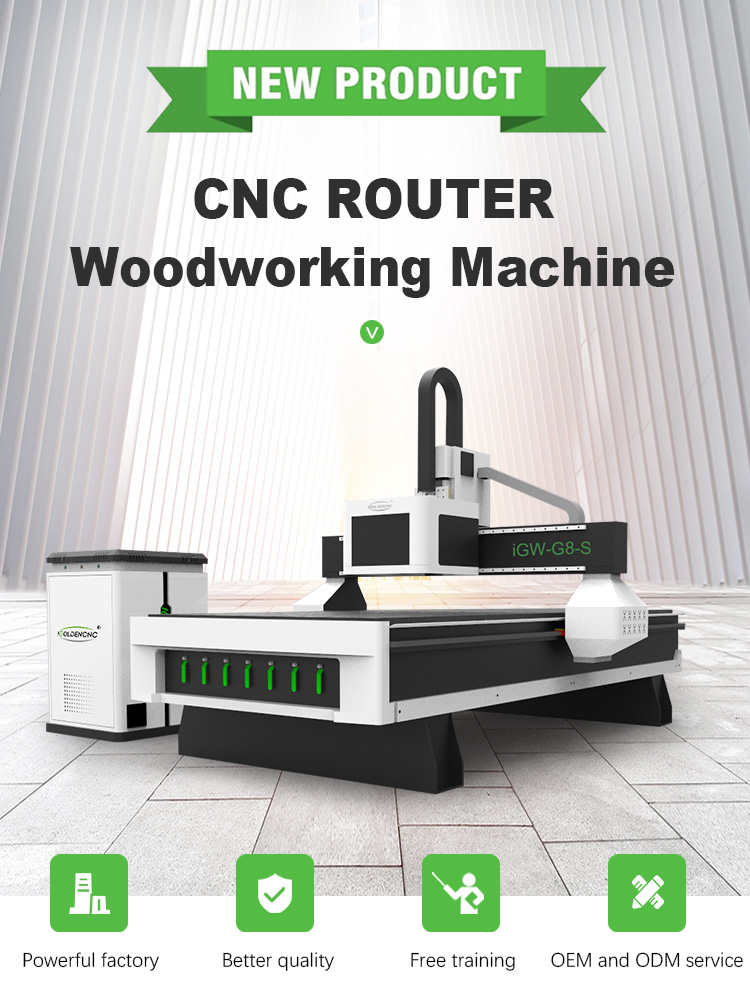

Our CNC Routers are industrial grade, fully automated machines. Affordability, power, and a no compromise design.According to your different processing materials and processing requirements, we also provide customized production of CNC engraving machine. Whether it is the machine parts selection or machine processing size, we are committed to satisfying your diverse processing needs with the highest price/performance ratio.

CNC Router is the perfect computer-controlled machine for cutting and engraving wood, acrylic, MDF, plastic, marble, rubber, epoxy resin, glass, foam, crystal and other materials. It typically falls into two types, ball screw-driven and rack & pinion-driven. More configuration options include carousel or linear ATC, double platforms, auto loading & unloading platforms, auto labeling platform, drilling head, etc.

iGOLDENCNC offers a variety of CNC wood router machines with many standard configurations for you to choose from. For instance, ATC CNC machines, 4 axis CNC machines, 3 axis CNC machines, multi-head CNC machines, mini CNC machines, best hobby CNC machines, stone CNC machines, and EPS CNC machines. In terms of worktable size, the best CNC router falls into 2x4, 4x4, 5x10, 4x8 CNC router, etc.

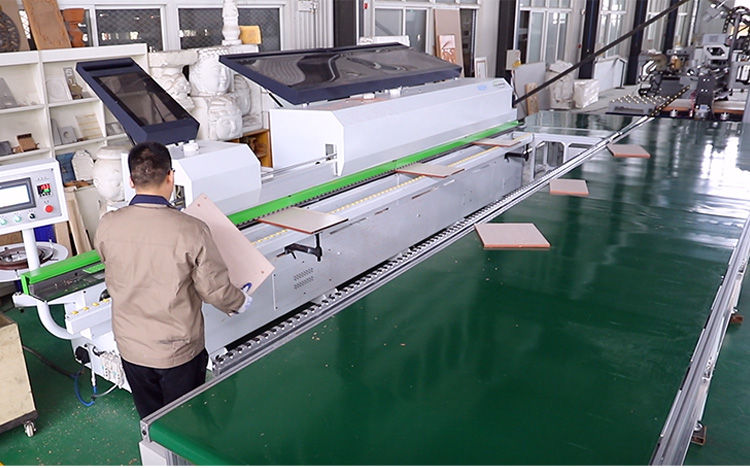

Our Edgebanders are affordable, yet capable machines for finished edges and seamless perfection.

• High feed speeds

• Optional pre-mill

• Ideal for cabinet and closet manufacturing

The edge banding machine, is used to band the straight and curved panel edges for custom furniture production. A woodworking edge banding machine falls into the manual edge banding machine and the auto edge banding machine, specially designed for shops and companies looking for efficient and precise edge banding service and solutions.

Most automatic industrial edge banding machines on the current market can realize basic 5 functions. These functions include gluing and banding, end cutting, trimming, scraping, and polishing.

The edge banding machine is a kind of woodworking machine dedicated for cabinet edge banding. It plays the role of edgebanding in the processing process of the furniture production line.The edge banding tape can have various materials, such as PVC, ABS, melamine, and wood veneer. It can band 0.4 to 3mm PVC edge banding tape to plywood, MDF, birch, walnut, maple, and other wooden panels in panel furniture and whole house custom furniture production.

Our saws are high-performance solutions for any style production environment. Exceptional control and smooth accuracy that you can trust.

• Built with servo motors and PLC controls

• On-board optimization, straightforward interface

• Programmable fences

Automatic Electric Panel Saw

Sliding Table Saw Machine

Sliding table saw makes cutting tasks easier and safer. It can cut panels at certain angles (22.5°, 45°, 90°) and can also make right-angle and inclined grooves.

The panel saw machine is also called the panel cutting machine, panel cutting saw, panel table saw, wood panel saw machine, panel saw cutting machine, etc.

It is designed to cut large panels of wood, MDF, plywood, melamine, etc. into small sections. The panel saw machine uses a rotating circular saw blade to size the panels.

With the large-scale application of panel furniture in the construction and decoration industries, traditional saws can no longer meet the needs of mass production and complex processes. The traditional sawing process has low work efficiency, poor precision, and consumes a lot of labor. However, the advent of panel saw machines has greatly improved work efficiency, making it quick and precise to saw wood. At present, combined with CNC technology, the CNC panel saw machine makes the entire cutting process fully automated. It can meet the needs of various wood cutting projects.

Our boring machines bring automated CNC manufacturing to another level. Precision and speed to transform your production output.

• Optimizes Delta servo motors

• Fully automated material fixturing

• Top and bottom routers allow for panel-processing capabilities

Double Head Side CNC Drilling Machine

CNC drilling is a kind of drilling technology that uses a CNC drilling bits (CNC router drill bits) or CNC drilling tools to punch round holes or square holes on the workpiece. And CNC drilling holes is typically used to accommodate screws or bolts for assembly. Sometimes CNC drilling can also be used for aesthetic.

The CNC drilling machine is an auxiliary equipment used in the panel furniture production line, which is consisted of various professional CNC drill kits like CNC drilling system, CNC drill table, and CNC drill bits to drill, groove, and punch. It is mainly used to drill vertical holes, horizontal holes, and side holes in wood, and make grooves on wooden boards or invisible parts. Therefore, it is also known as wood drilling machine, wood square hole machine, woodworking horizontal boring machine, vertical CNC drilling machine, wood hole machine, and side hole drilling machine.Especially in the furniture production line, wood CNC drilling machines play an irreplaceable role. It can not only realize flat hole punching, vertical hole punching, and side hole punching, but also can drill other multiple angle holes.

content is empty!