Views: 22 Author: Site Editor Publish Time: 2022-11-30 Origin: Site

Fiber laser welder is composed of welding host, welding workbench, water cooler and control system. This series of welder equipment has a number of worktables to choose from, which is 3-5 times of the speed of traditional fiber transmission laser welding machine, and can fully meet the needs of customers in different industries. The cnc laser welder is suitable for welding gold, silver, titanium, nickel, tin, copper, aluminum, stainless steel and other metals and the corresponding alloys. It can realize precision welding between the same kind of metal and different metal. It has been widely used in aerospace equipment, shipbuilding, instrument and meter, mechanical and electrical products, automobile manufacturing and other industries.

Handheld laser welding machine adopts hand-held welding head, which has the characteristics of no consumables, small size, flexible processing, and low operation and maintenance cost.

This handheld fiber laser welding machine is one of the most popular welding machines in the current world. It adopts a handheld welding head which is very convenient to operate. It has high welding efficiency and small thermal impact. This machine can weld various metals including thin metal plates.

Portable fiber laser welding machine adopts continuous fiber laser source. It’s a fiber and metal welding machine.

Adopting industrial integrated design, the structure is compact and beautiful, laser beam mode is good and can make the energy concentrate. So the machine’s performance is stable and reliable, with long lifespan consumables.

The fiber laser welding head adopts water-cooled design, so it won’t get over-heated during welding, small diameter, easy for hand-holding.

This automatic laser welding machine can realize a quick and precise fiber laser welding on various metal materials, such as stainless steel, carbon steel, manganese steel, galvanized, and so on. In addition, it has the function of auto focus. It can focus on the welding parts, welding points, straight lines, circles, squares, etc. This laser welding machine can meet your mass processing needs and has been widely used in many industries.

Automatic fiber laser welding machine (optional 1000W, 1500W, 2000W, 3000W and etc.), six-axis robot, swing welding joint can complete any space trajectory, and can be used with CCD monitoring system to observe the welding process in real time.

Wobble weld head can be adjusted laser beam width, frequency and wobble modes. In addition to the wobble modes, both wobble frequency and amplitude can be adjusted for process optimization.

The wobble welding head has a laser integration function to assist in improving the laser energy conversion rate. Wobble welding heads are designed to provide the

highest laser power handling capability in the industry in a completely sealed and lightweight package. These process heads provide effortless integration with HS lasers

and offers improved weld quality and better visual finish. Available in multiple configurations with the broadest focus and collimator lens options, the Wobblersare the

ultimate tool to weld a multitude of different material types and thicknesses.

Sheet metal processing, railway transportation, automobiles, construction machinery, agricultural and forestry machinery, electrical manufacturing, elevator manufacturing, household appliances, food machinery, textile machinery, tools Processing, petroleum machinery, food machinery, kitchen and bathroom, decorative advertising, laser external processing service

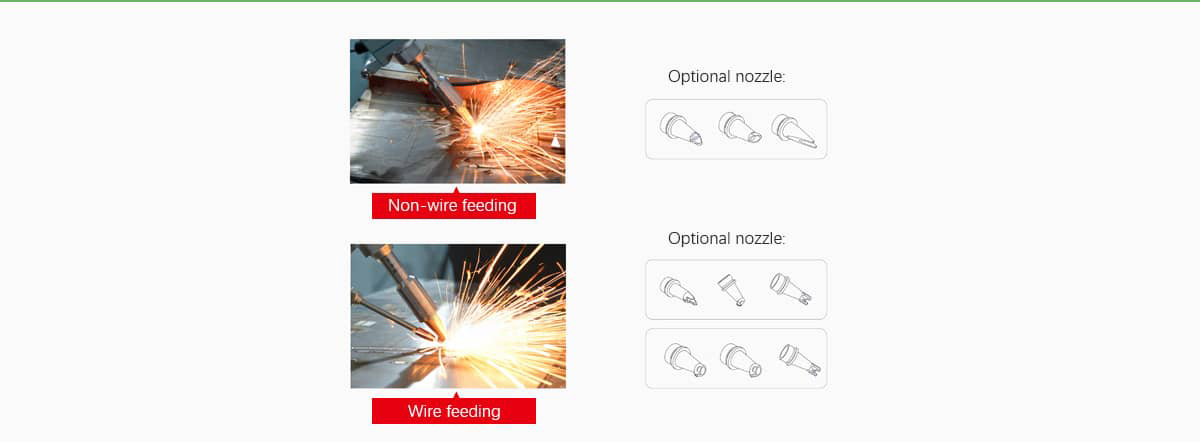

iGoldencnc’s handheld laser welding machine has two welding modes.

Customers can choose between wire feeding or non-wire feeding according to their own products.

The switching is simple and practical.

Laser Source

The laser adopts water-cooled heat dissipation and rack-mounted chassis design.

It has many advantages such as high electro-optical conversion efficiency, low energy consumption, compact structure, adjustment-free maintenance, and easy integration for customers.

It is industrial laser welding and other Ideal light source for application.

HANLI Chiller

1. The cooling capacity is up to 1400W, and environmentally friendly refrigerants can be used;2. Small size, long life and durable, easy to operate;3. The temperature control accuracy can reach +0.3C;4. The intelligent thermostat has two temperature control modes, which are suitable for different use occasions; it has a variety of settings and fault display functions;5. With multiple alarm protection functions

Integrated structure design, comply with majority of the laser source available in the market;

Low running cost, only 1~2Kw/h electricity and little nozzle cost;

Dual-temperature control water chiller, support both laser source and welding head, ensure long term stable operation;

O-type, Line-type and dot-type wobble welding types for option, swing width ranges 0~5mm;

Equips digital display barometer, with low pressure alarm function to help adjusting air pressure;

Touch screen control panel, easy for parameter adjusting, less relying on skilled welding technicians;

Ergonomic design welding head, optional elastic weight reducer, make it easy for long time operation.

content is empty!