Views: 9 Author: igoldenCNC Publish Time: 2026-01-07 Origin: igoldenCNC

Precision and efficiency are crucial when cutting stone. Whether you're working with granite, marble, or quartz, the right equipment makes all the difference. CNC stone cutter is designed to meet these needs, providing accurate, versatile cutting for professionals. In this blog, we will explore the features, benefits, and applications of CNC stone cutters, explaining why they are essential for achieving flawless results in stone cutting.

The CNC Stone Cutter is also commonly referred to as a "CNC Stone Cutting Machine," "Stone CNC Router," or "Stone Engraving Machine." It is a specialized CNC machine used for cutting and engraving stone materials, commonly applied in the processing of granite, marble, and other natural stones. CNC stone cutter is a machine that uses Computer Numerical Control (CNC) technology to automate the process of cutting, carving, and shaping stone materials. These machines use powerful diamond blades and tools to cut through hard stones like granite, marble, limestone, and engineered stones like quartz. The precision provided by CNC technology ensures each cut is accurate and consistent.

By programming the machine with CAD (Computer-Aided Design) files, operators can create precise shapes, intricate engravings, and complex cuts with minimal human intervention. This makes CNC stone cutters ideal for industries that require high levels of precision, such as countertop fabrication and monument

engraving.

High-precision CNC stone cutters offer many advanced features that set them apart from traditional stone cutting methods. Some of these key features include:

Accuracy and Precision:CNC stone cutters provide exceptional accuracy. The machine follows pre-programmed paths to execute cuts exactly as specified. This precision is crucial for projects that require tight tolerances, like custom countertops or engraved memorial stones.

Durable Diamond Blades:Diamond-tipped blades are commonly used in CNC stone cutters. These blades are ideal for cutting through hard materials like granite and marble. Since diamond tools stay sharp for longer than traditional tools, they reduce the need for frequent replacements, cutting maintenance costs.

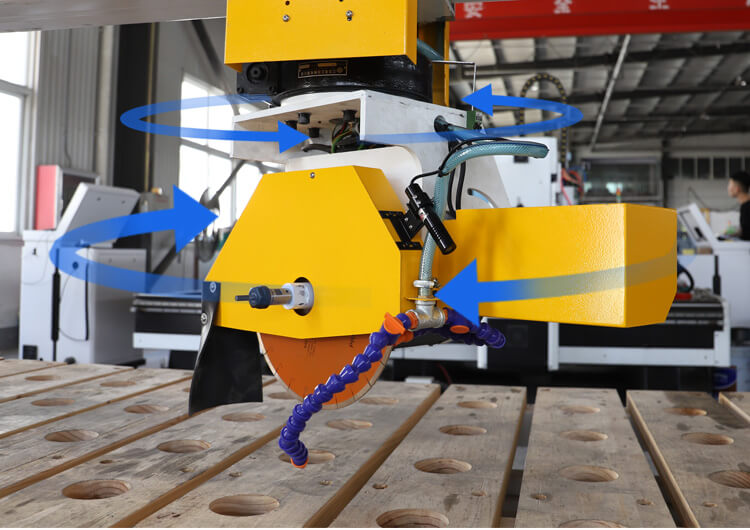

Multi-Axis Movement:Many CNC stone cutters have multi-axis control. This allows them to cut stone from multiple angles simultaneously, making it easier to create complex shapes and detailed engravings. Whether you need to make straight cuts or intricate 3D designs, multi-axis capabilities make it possible.

Water Cooling System:Cutting stone generates heat that can damage both tools and material. To prevent overheating, most CNC stone cutters have a built-in water cooling system. This helps maintain a consistent temperature and prevents excessive wear on the cutting tools.

User-Friendly Software:CNC stone cutters are equipped with software that allows for easy design and execution of cuts. Operators can upload CAD files, adjust cutting paths, and modify settings as needed. We design the software to be intuitive so that even those new to CNC machines can quickly get up to speed.

Automatic Tool Changer:Some high-precision CNC stone cutters come with an automatic tool changer. This feature allows the machine to switch between different tools automatically without manual intervention, improving productivity and reducing downtime.

CNC stone cutters provide several key advantages for businesses in the stone industry. These benefits include:

Enhanced Accuracy and Consistency:CNC stone cutters eliminate the risk of human error.The operator executes each cut according to the exact specifications, ensuring consistency across every piece. This is especially important for projects where precision is critical, such as memorial engravings and custom stonework.

Faster Production Times:By automating the cutting process, CNC machines allow you to work faster. Tasks that would take hours by hand can now be completed in a fraction of the time. This leads to higher productivity and enables businesses to meet tight deadlines.

Lower Labor Costs:CNC stone cutters reduce the need for skilled labor. While operators still need to program and monitor the machine, the automation of the cutting process reduces the need for manual intervention. This can result in cost savings for businesses that rely on stone cutting equipment.

Minimized Material Waste:CNC machines optimize cutting paths to reduce waste. This is particularly important when working with high-cost materials like granite and marble. By minimizing waste, businesses can increase their profit margins while using materials more efficiently.

Versatility for Various Applications:CNC stone cutters are incredibly versatile. They can handle a wide range of tasks, from simple straight cuts to complex multi-dimensional designs. Whether you’re creating countertops, decorative stone elements, or custom sculptures, CNC stone cutters can meet your needs.

Custom Designs:CNC stone cutters allow you to create unique, custom designs for your clients. The ability to import CAD files and modify cutting parameters means you can offer personalized products and services that stand out in the marketplace.

Various industries, including construction, monument engraving, and interior design, use CNC stone cutters. Some of the most common applications include:

Countertop Fabrication:CNC stone cutters are widely used for making custom countertops. They can cut and shape materials like granite, marble, and quartz to precise specifications. The machines can create edge profiles, sink cutouts, and even intricate patterns, offering endless possibilities for kitchen and bathroom designs.

Memorial and Gravestone Engraving: CNC stone cutters are also used for engraving memorial stones, tombstones, and gravestones. The precision of the machine allows for clear, detailed engravings of names, dates, and custom designs. This is particularly important for creating lasting memorials that are both beautiful and legible.

Architectural Stonework: In architecture, CNC stone cutters are used to create decorative stone elements like columns, arches, and tiles. These machines can cut complex shapes and profiles, helping architects and builders create custom designs for commercial and residential projects.

Stone Sculpting: Many artists use CNC stone cutters to create sculptures and artistic stone pieces. These machines allow artists to carve fine details and complex shapes with high precision, enabling them to bring their creative visions to life.

Industrial Stone Products: CNC stone cutters are also used in the production of industrial stone products, such as tiles, slabs, and panels. These machines ensure that each piece meets the required specifications, making them ideal for large-scale production runs.

Selecting the right CNC stone cutter for your business is crucial for maximizing efficiency and ensuring the best results. Here are some factors to consider when making your decision:

Material Compatibility: Ensure the CNC stone cutter is capable of cutting the types of stone you regularly work with.Some machines suit harder materials like granite better, while we find others work well with softer stones like marble.

Cutting Capacity: Consider the size of the stone slabs you usually work with. Make sure the CNC stone cutter has an adequate worktable size and cutting capacity to handle your largest projects.

Spindle Power: The power of the spindle motor affects the machine’s ability to cut through thick, dense materials. Choose a cutter with sufficient power to handle the types of stone you cut most frequently.

Software Integration: Ensure the CNC machine is compatible with your design software. Many CNC stone cutters work with CAD and CAM programs, which makes it easy to create and modify designs.

Customer Support: Look for a supplier with strong customer support, including training and technical assistance. Companies like IGOLDENCNC offer comprehensive after-sales support, ensuring you get the most out of your machine.

A high-precision CNC stone cutter is a powerful tool for professionals who need to create accurate and detailed cuts in stone. Whether you’re working on countertops, gravestones, or custom stone sculptures, CNC technology provides the precision, efficiency, and versatility you need. By investing in a CNC stone

cutter, you can improve productivity, reduce waste, and offer high-quality products to your clients.

For businesses looking to upgrade their stone-cutting equipment, IGOLDENCNC offers some of the best CNC stone cutters on the market. With a focus on durability, precision, and customer support, IGOLDENCNC is an excellent choice for anyone in the stone fabrication industry.

To learn more or request a quote, visit IGOLDENCNC’s official website.