Views: 13 Author: Site Editor Publish Time: 2022-12-27 Origin: Site

There are plenty of solutions available if you’re searching for a CNC router for Hobbyist or a tabletop CNC cutter for your DIY. Many firms provide inexpensive CNC routers that enable you to carve complicated operations with pinpoint precision from the convenience of your own home.

Laser cutters and laser engravers are similar machines that can cut or engrave images or shapes into tough materials. Industrial laser cutters can cut even the toughest metals like stainless steel and nickel, whereas more affordable laser cutters, such as DIY laser cutter kits, can cut wood, acrylics and other softer materials.

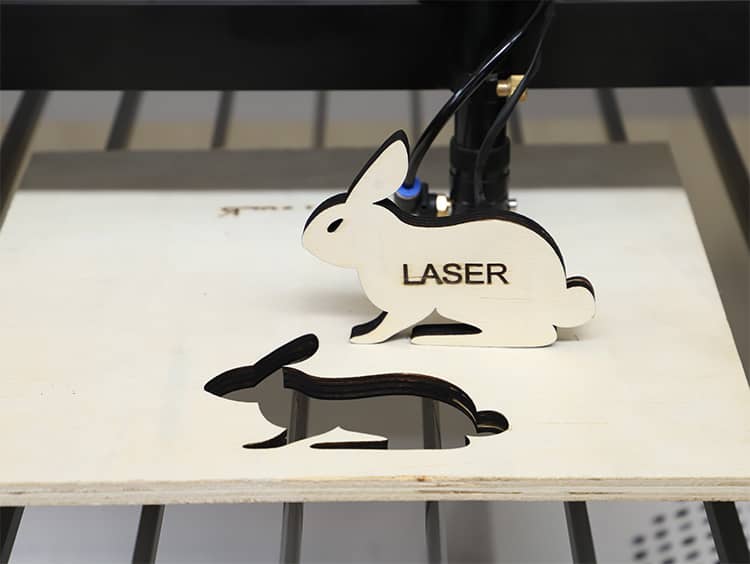

best cnc laser cutting machine for hobbyist

Co2 Precision Cutting Machine is used for the processing of leather, electronic paper, PCB and composite materials, high-precision cutting of non-metallic film materials such as gdf film, polarizer, touch screen PET, OCA, tablet, flexible OLED, etc. and other material cutting.

6090 medium-format laser machine is designed for serial production and cutting of non-metallic materials. The machine is characterized by high rigidity (frame construction), high-precision processing (positioning accuracy up to 0.01 mm) and ease of operation.

This machine is a powerful base for small and medium-sized production and a perfect addition to a large laser shop.

The Co2 laser cutting machine is mainly for non-metal cutting, engraving, marking, it also be named as: CNC laser engraver machine, CNC laser cutter machine, Laser etching machine,laser wood engraver machine.

The popular power of Co2 laser engraving cutting machine is: 40w, 50w, 60w, 80w, 100w, 130w, 150w, 260w, etc.

6090 Laser Engraving Machine Parameters:

| Model | 6090 Laser Cutting Machine |

| Working area | 600mm x 900mm |

| Laser power | W2/W4/W6/W8 |

| Laser type | CO2 sealed laser tube, water-cooled |

| Cooling way | Water cooling CW3000/5000/5200 |

| Engraving speed | 0-60000cm/min |

| Cutting speed | 0-30000cm/min |

| Power supply | 220V/50Hz, 110V/60Hz, |

| Laser energy control | 1-100% software Settings |

| Graphic format supported | BMP, PLT, DST, DXF, AI |

| Software supported | CorelDraw, Photoshop, AutoCAD, Tajima |

| Driving system | 3-phase stepper motor with decelerator |

| Air assist | Air pump |

| Dichroic Cutting | Yes |

| Optional part | Red light pointer |

| Applicable material | Suits, Textile, Fabric, Cloth, Jeans, Leather, Acrylic, Wood, Rubber, Paper, Rubber, Dual Color Board, etc... |

CO2 Laser Engraving Cutting Machine Details:

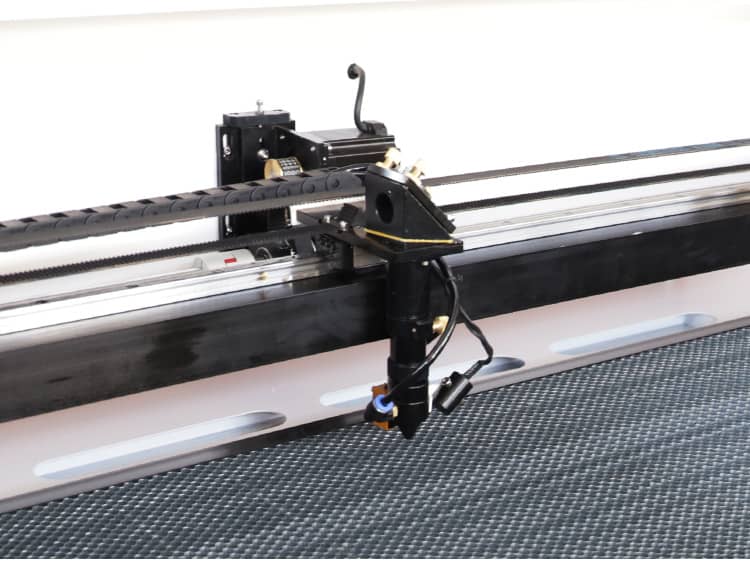

Industrial grade laser head

The engraving speed is fast, the service life is long, and the clear effect is better.

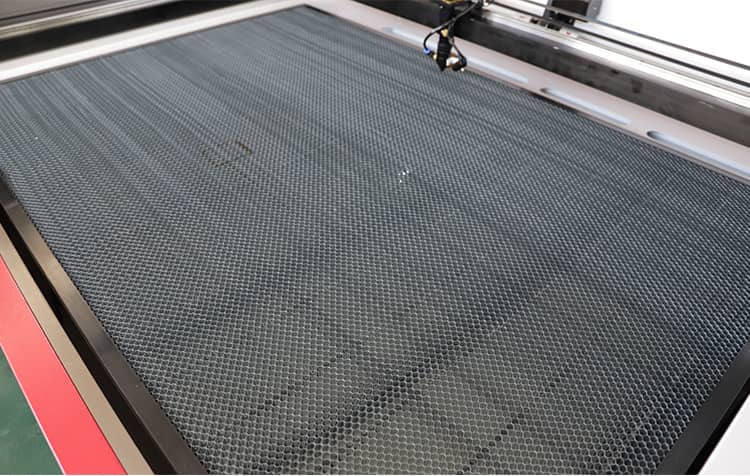

Cellular platform

High strength not easy to deform, high structural stability, sound absorption, heat insulation, suitable for processing small crafts.

Optional

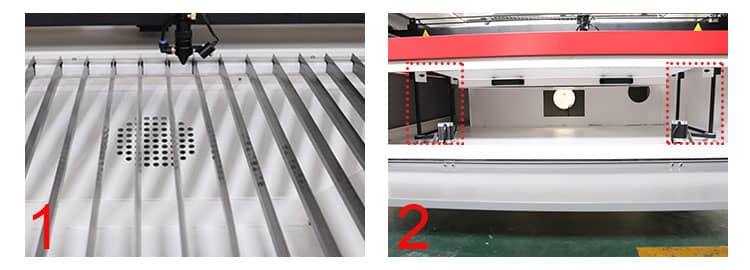

1. Knife countertop

High hardness, not easy to deform, suitable for cutting and engravinglarge materials.

2. Lifting device

The lifting device can be added according to customer needs

Beijing Reci laser brand w6 laser tube

Industrial grade laser tube, stable power, faster cutting and long life.

Ruidaacs control system

Humanized control system, easy to learn, intelligent and convenient.

Stepper motor | Water cooler

Receiving drawer | Taiwan guide and Transmission belt

Laser cutting is the process of intensifying light beams using optical amplification to create high-powered lasers, which are then used to cut or engrave the desired materials. Controlled by a motor system in the machine, the laser will cut and engrave your desired design or pattern. The machine knows how to manipulate the laser because it’s instructed by the design software you use to create the image.

The results are sharp and precise and are created in the nth of the time it would take using traditional methods.

As far as what laser cutting and engraving can be used for, the possibilities are endless. Personalize leather wallets, streamline furniture constructions, and even engrave your own logo onto a cup! Laser cutters work on dozens of materials, giving you plenty of ideas to accomplish.

Both techniques use custom models or designs to create accurate parts and models. Most laser cutting machines can do both, depending on the laser’s power and depths it can cut. There are however a few subtle differences between the two:

Laser Cutters: laser cutters use powerful lasers to cut entire pieces off your workpiece to create your final model. These cutters typically use vector files to accurately cut your chosen part, shaving chips off and smoothly separating these areas off in a process of subtractive manufacturing. Laser cutters typically use CO2 lasers, and even cheap laser cutters can cut quickly through acrylics, plastics and wood.

Laser Engravers: rather than cutting all the way through the material, laser engraving machines engrave an image, logo or graphic on top of your chosen material. Engraving is often used for branding products or signage, but can also be used to engrave entire greyscale artwork onto wood. This is done via image files such as jpg, svg, png or ai files, using methods such as grid engraving where the laser moves horizontally, line by line, removing certain depths of material to create a contrasting and readable image. Engravers use short focal length lasers with fine spot sizes for accurate engraving.

Laser marking is also a process wherein rather than engraving or cutting, physical contrasting marks are made on the material by heating it to separate elements that show up to the naked eye, without making any indentations.

There are three main types of lasers that you’ll encounter during your searches, these are fiber, CO2, and crystal lasers.

CO2 lasers, or gas lasers, are one of the more common types seen for at-home and small business use. It works by running electricity through a gas-filled tube, which is usually a mixture of gases like CO2, nitrogen, and helium. There are mirrors on each end of the tube, one reflective and one partially reflective, that let light through for the beam.

CO2 lasers range from 25 to 100 w tubes and are best for non-metallic materials. So wood, acrylics, leather, textiles, and glass all do well with a CO2 laser.

Crystal laser cutting on the other hand works by generating beams from nd:YAG (neodymium-doped yttrium aluminum garnet) and nd:YVO (neodymium-doped yttrium ortho-vanadate) crystals. These high-powered lasers are reserved for industrial use and work best with coated and non-coated metals and plastics.

And lastly, fiber laser cutters use fiberglass to amplify a “seed laser”, and belong to a class called “solid-state lasers” alongside nd:YAG. Fiber lasers work well with metals and offer a more stable and energy-efficient alternative to crystal lasers. They can be used at home and for small businesses for metal laser cutting.

content is empty!