Views: 9 Author: Site Editor Publish Time: 2022-12-08 Origin: Site

First, the CO2 laser metal cutting machine price ranges from $2,000 to $20,000. While the fiber laser metal cutter price ranges from $20,000 to $200,000.

There are a lot of factors that can affect the metal laser cutting machine price, such as types, kits, brands, manufacturers, power, size, functions, etc. Therefore, the metal laser cutter cost will show a great difference.

Indeed, the metal laser cutting machine is a kind of CNC laser machine or laser equipment that can cut metal materials. So it can be divided into the following two main types.

In fact, a fiber laser cutting machine is specially designed for processing metal materials. And it can cut metals with different shapes, no matter it is a metal sheet or metal tube. Depending on this, the fiber laser metal cutter can be divided into the metal sheet fiber laser cutting machine, metal tube fiber laser cutter for sale, and metal sheet and tube fiber laser cutter.

As we all know, CO2 laser cutting machine is usually used to cut and engrave nonmetals. However, the mixed CO2 laser cutting machine can also realize CNC metal laser cutting. But they can only laser cut some thin metals within 2mm. And the processed metals are usually carbon steel and stainless steel. Moreover, it is not recommended to use the CO2 laser beam to cut and engrave the metal materials for a long time. Because the long-time working will damage the laser tube.

It is also named a metal laser cutter that adopting a fiber laser generator as a light source. It has many advantages, such as high processing accuracy, fast cutting speed, narrow cutting seam, minimum heat-affected zone, smooth cutting surface, and no burr.

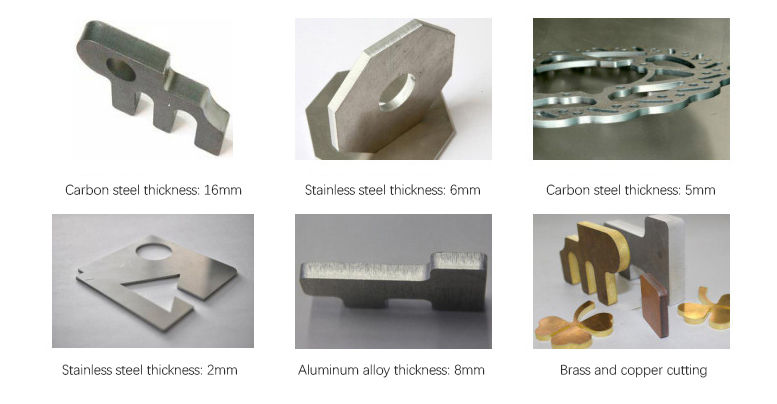

There is no doubt that iGOLDEN CNC Machinery can provide you with both fiber laser and CO2 laser to cut or engrave metal materials. The fiber laser beam can cut most of the metals, such as stainless steel, carbon steel, aluminum, brass, copper, steel, titanium, zinc, alloys, etc. And the laser cutting thickness can reach 50mm. While the CO2 laser beam can only cut and engrave very limited thin metal sheets, such as 2mm stainless steel sheets and 1mm carbon steel panels.

1. Sheet Metal Processing Industry

2. Advertising Industry

The advertising production industry usually uses metal materials. High-precision metal laser cutting technology does not require secondary rework, which greatly improves work efficiency and saves enterprise costs.

3. Kitchenware Industry

Range hoods and gas appliances often use a lot of sheet metal. The metal laser cutter for sale can realize customized and personalized product development, improve the yield, and solve the troubles of kitchenware manufacturers.

4. Automobile Manufacturing

There are also many precision machinery parts in cars, such as car brake pads and doors. The metal laser CNC cutting machine can be processed in batches quickly, with high precision, high efficiency, no burrs, and one-time forming. As the result, the safety of the car is improved and the cutting accuracy is also guaranteed.

5. Fitness Equipment Industry

Fitness equipment has a strict requirement of specifications and shapes. CNC metal laser cutting, on the other hand, is highly flexible and can be customized and flexibly processed for different metal tubes and sheets.

6. Shipbuilding Industry

The best metal laser cutter has the advantages of good cutting seam quality, good verticality, no slag inclusion, thin oxide layer, smooth surface, small thermal deformation, and high precision curve cutting. It can achieve barrier-free cutting of high-strength ship plates.

7. Construction Machinery Industry

The construction machinery industry needs to cut a large number of round holes, square holes, and special-shaped holes on metal plates of various thicknesses. Besides, it also requires very high precision. Using a metal laser cutting machine can quickly punch holes and cut out the ideal shape, which greatly improves the production efficiency and product quality.

content is empty!