Views: 10 Author: Site Editor Publish Time: 2022-12-22 Origin: Site

What is the working principle of the wood laser engraver machine?

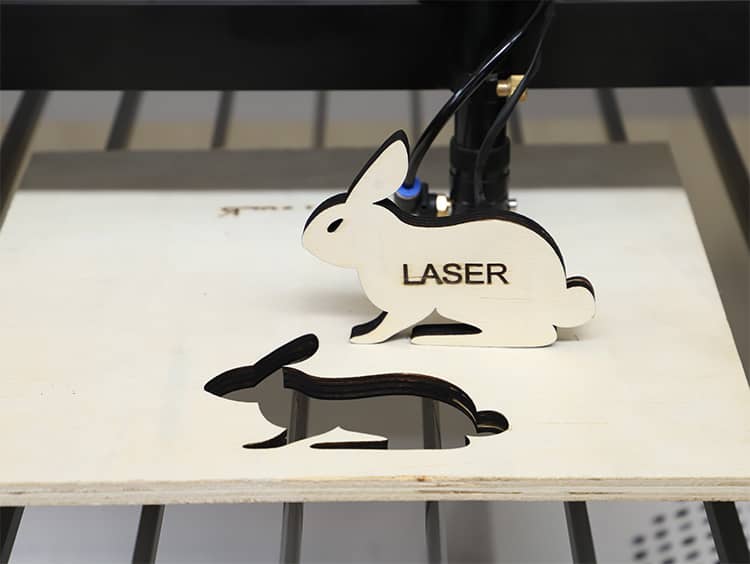

Laser engraving is the energy released when the laser beam is irradiated to the surface of the workpiece to melt and evaporate the workpiece to achieve the purpose of cutting and engraving. It has high precision, fast cutting, not limited to the limitation of cutting patterns, automatic layout saves material, and smooth cutting, Low processing cost and other characteristics, will gradually improve or replace the traditional engraving process equipment.

The principle of laser engraving is: the laser beam is transmitted through the optical mechanism and focused on the surface of the material, and the material at the point of action of the high-energy-density laser beam is rapidly vaporized to form pits. Use the computer to control the XY console to drive the laser head to move and follow the requirements Control the laser switch, the image information processed by the software has been stored in the computer in a certain way. When the information is read from the computer in order, the laser head will follow the scanning track from left to right from top to bottom line by line Scan back and forth. Whenever a “1” point is scanned, the laser is turned on, and when a “0” point is scanned, the laser is turned off. The computer stores information in binary, which is exactly the same as the laser switch. Match.

Also known as gas lasers, the CO2 lasers use carbon dioxide gas to generate laser beams. When electricity is passed through the gas, it emits laser light with a wavelength of 10,000 nanometers.

This wavelength is best suited for working with non-metallic surfaces like leather, wood, and plastics.

Engraving and cutting wood with a laser offers a number of benefits. Not least because of this, the process is used as standard in many industries.

Quick customisation: unique engravings and personalising work can be produced in seconds flat. Coloured inscriptions provide a decorative appearance.

No wear: when engraving wood with a laser, the laser does not become worn and it is not necessary to buy additional tools. This means there are no costs resulting from tool wear, as is the case in milling, for example. The quality of the cuts is consistently high.

No fixing necessary: laser work can be carried out as a fully contactless process. In contrast to milling, it is not necessary to fix the product in place. This simplifies the process, thus increasing throughput and profitability.

Simple work processes: You can create your desired design in your usual graphics program. You don’t need any extra software or comprehensive training. The template is sent to the laser via a print command and can be put into effect quickly and easily.

Clean and precise: no chips are created when engraving wood with a laser, which guarantees a clean workspace. The engravings impress with their extreme precision – even for small patterns with low radii.

The wood laser engraving machine is the latest 1390 CO2 laser engraving machine. This plastic engraving machine is suitable for a variety of materials, with a smooth cutting edge, no polishing, low noise, no dust, fast processing speed, high precision, less waste, and efficiency high advantage. It is the best choice for upgrading acrylic laser engraving machines in various industries. The laser engraving machine price is cheap.

Wood cutting and engraving are two of the most popular applications for the laser because they can encompass so many different projects. From cabinetry to photo frames to knife handles, Epilog Laser systems are used in almost every woodworking category you will run across. Whether you are working with hardwoods, veneers, inlays, mdf, plywood, walnut, alder, or cherry, you can engrave amazingly intricate images with a laser system.

content is empty!