Views: 8 Author: Site Editor Publish Time: 2021-06-02 Origin: Site

3 axis CNC router table is a CNC routing machine with X aixs, Y axis and Z axis, it will go along three different axis at the same time. X-axis will move from left to right, Y-axis will move from front to back, and Z-axis will move up and down. 3 axis CNC router table are used primarily for machining flat, 2D and 2.5D parts. 3 axis CNC router table is also known as 3 axis CNC machine, 3 axis CNC cutter, 3 axis CNC router kit, 3 axis CNC carving machine. The functional software behind any CNC machine is its CAD/CAM software. CAD software allows users to create the designs they wish to engrave. After completing this design, the CAM software converts the design into toolpath code that the machine can understand. The computer then converts this code into a signal that controls the movement of the machine's drive system. The drive system includes a spindle, which is the part that saves the actual machine position. The spindle rotates 8,000 to 50,000 times per minute to cut the material. In short, users create designs and use software to make instructions for the machine.

【PREMIUM QUALITY】- Made of 2020 aluminum profiles and black injection molding material for Long-term use and high precision. The working travel of this machine is 240(X)x180(Y)x40(Z)mm.

【EASE OF USE】- According to the instructions, the machine is easy to assemble. Simply connect to computers via USB port, and controlled by GRBL. Supports windows XP SP3, win7, win8, win10,(32/64) and Linux system.

【CONVENIENT CONTROL】- Comes with an ingenious GRBL control board, featuring dual Y-axis, four-axis drive and full functionality.

【HIGH PERFORMANCE】- Equipped with T8 screw rods driving units, three 42 stepper motors, and a 775 (12-36V)24V spindle motor with rotational speed of 10000r/min.

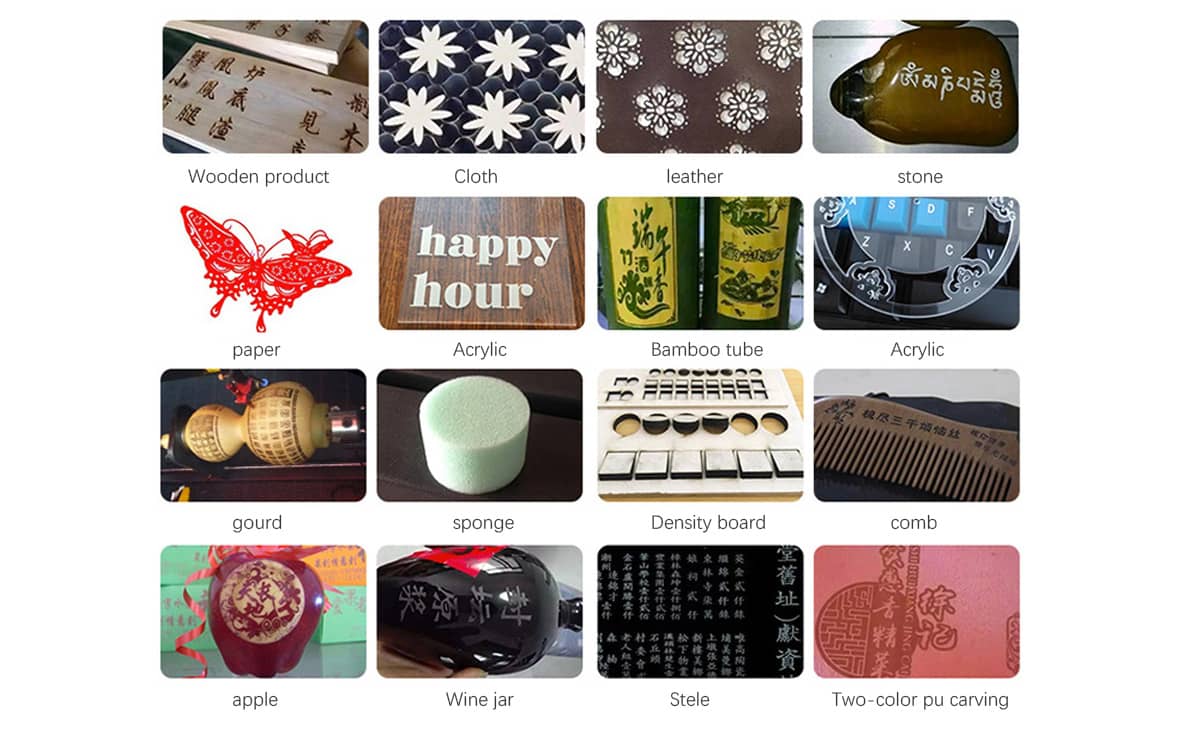

【VERSATILE USE】- Used to engrave all types of plastics, soft aluminum, acrylics, PVCs, PCBs, etc.

CNC Preventative Maintentance Checklist

Our service technicians created a recommended CNC router preventative maintenance checklist to keep CNC machines at your factory running smoothly. Scheduled 3 axis CNC router table can help avoid costly downtime, so don’t skip on these important steps.

1. Daily

Clean all debris off machine (blow off with pressurized air after every part)

Inspect the following:

Tool holders for cleanliness **

Internal taper of spindle motor**

2. Weekly

Check pneumatic oil level in regulator*

Empty water in regulator or separator

Inspect blower pre-filter and main filter, then clean as required

Grease all leadscrews and linear guides***

3. Monthly

Upload all machine data via RS232 or Ethernet (machine parameters and program files)

Copy machine data onto CD or USB drive, then store in a safe location

Inspect all of the following:

Pneumatic connections – listen for leaks and inspect enclosures for excess oil*

Electrical enclosures – check for cleanliness (power to machine should be off)

Belt and pulley assemblies – check for tightness and belt integrity

Clean, then grease fourth and fifth axis gear assemblies***

4. Semiannually

Deep clean all lead screw and ball nut assemblies by flushing ball nuts with WD40

Clean dry assemblies, then perform error calibration on all axes

Inspect the following:

All wiring connections in machine enclosures

Brushes in DC brush servo motors

Parameters

Model | 1325(4*8feet) |

Structure | Seamless steel welded |

Table | Vacuum table with t slot |

XYZ working size | 1300*2500*200mm |

XYZ transmission | XY axis is helical rack and gear,Z axis Ball Screw |

XYZ guide rail | Famous Taiwan Hiwin Line 20mm Square guide way |

Spindle | 6kw italy HSD air cooling spindle |

Inverter | Well known china Fuling 7.5kw |

Motor | Servo motor |

Controller system | DSP A18 control system |

Voltage | 220/380v, 3phase 50HZ |

Router bits | 10pcs for free |

Application

content is empty!