Views: 12 Author: Site Editor Publish Time: 2022-12-23 Origin: Site

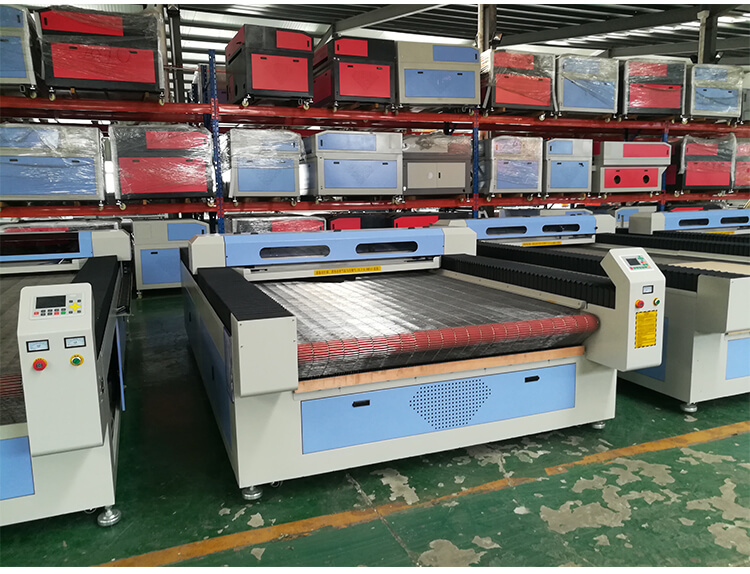

Fabric laser cutting machine uses CO2 laser cutting technology on fabrics. This machine is quite precise and is able to cut without making errors which is inevitable otherwise. The fabric laser cutting machine doesn’t apply much pressure to the fabric ensuring that it doesn’t get destroyed in the process. The machine can work with wide variety of material including but not limited to cotton, silk, nylon, leather etc.

Advantages of Laser Cutting Machine for Cutting Fabric

Laser fabric cutting systems can cut any computer-designed shape. Due to the combination of laser and computer technology, the user can realize the laser cut output as long as the design on the computer, and the working can be changed at any time, and the product can be cut while designing.

Laser fabric cutting systems break the traditional manual and electric shears, which are slow and difficult to typesetting, and fully solves the problem of inefficiency and waste of materials. The cutting speed is fast and the operation is simple. You only need to input the graphics and dimensions to be cut into the computer, and the machine The whole piece of material will be cut into the finished product you need, without tools or molds, using lasers to achieve non-contact processing, which is simple and fast.

Laser cutting machine is more precise and uses less energy while cutting different materials. Its precision and efficiency are commendable over traditional cutting methods. Laser cutting technology also enables us to cut complex shapes without the need for tooling and at a similar or faster speed than other cutting methods.

Also, laser cutting and engraving machines have numerous applications. A clear example where Leather laser cutting and engraving machines have made a big impact is in the handling of jeans. Lasers are primarily used in the textile industry for cutting, marking, and engraving fabrics. In the process, the material is laid out with the outline for further work on the same. Because of the ability of the laser to be positioned over any particular point with a high degree of accuracy, line lasers are making their presence felt in many different ways in this industry vertical. Such lasers also cause a superficial burn on the fabric which can be used for identifying all drawn markings. Known for their high degree of accuracy, these line lasers are instrumental in marking out multiple layers of cloth kept one on top of the other.

Non-Contact Process

The laser cutting machine cuts fabric accurately without touching the fabric which means that the garment comes out as untainted. The beam of the laser cutting machine doesn’t physically touch the materials instead it cuts the material with its heat thereby minimizing the cost involved in it. Laser cutting offers precision just like it is done by hand, but at a much faster pace, making it more practical and also allowing for lower price points.

Low Power Consumption

This is an important advantage in a world that is looking to work smarter, not harder by driving up production while lowering costs. A cutting machine will only use around 10kW of power, where other cutting processes use a more 50kW mark.

A Safer Method

With increased production comes the need for increased safety too. Laser cutting cuts the material with much efficiency and precision. Accuracy, clean cuts, sealed fabric edges and prevents fraying, this technology has become very popular in the fashion industry.

Laser cutting machines can cut almost anything with such precision. They have been widely used in the production of fabrics and textiles such as cotton, polyester, nylon, silk, and leather. Laser cutters have the ability to cut fabric without pressure, therefore ensuring no rough edges or fraying during the process. Laser cut fabrics are typically found in luxury apparel that you may see in high end clothing stores, couture shops, and fashion runways.

CNC fabric laser cutter machine is an ideal solution for straight or curving cutting of felt, textile, cloth, leather. We can design and nest patterns on the computer, then use laser cut machine for fabric with no die required, it works at a very high speed and accuracy, saves much time, reduces material loss.

As we mentioned previously, CO2 laser cutting machines can work on any type of fabric material. Below is a list of common fabrics and textiles that would work well with laser cutting technology:

Cotton

Felt

Fleece

Denim

Lace

Linen

Polyester Silk

Others (Acrylic, Alcantara, Softshell)

You may also be surprised that laser cutting machine can also cut and engrave designs on the leather used to make items such as bags, belts, boots, and shoes.If you want a hassle-free purchase, top quality, and rock bottom prices? Check out our laser machines. We are a team of experts with extensive laser cutting and engraving knowledge. We can help answer your questions and help the growth of your business with a iGOLDEN Laser. Give us a call to learn more about laser cutting technology and how it can be applied to your fabric and textile production.

content is empty!