Views: 34 Author: Site Editor Publish Time: 2023-01-06 Origin: Site

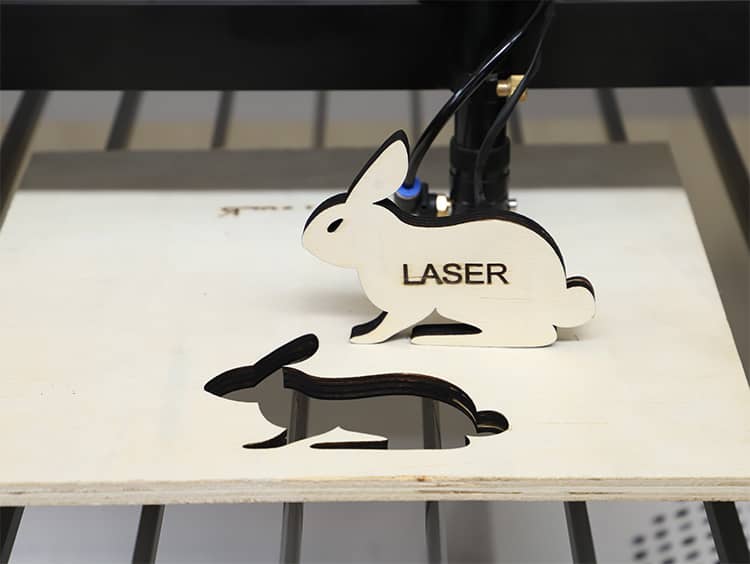

The woodworking is a craft as old as time, and there is a reason that it remains popular even today. There is a certain, rustic beauty to wood which makes it a timeless material of choice for hundreds of applications. Fortunately, laser technology has made it possible for woodworking to be easier, faster, and more accessible to amateurs and professionals alike.

Why choose a wood laser cutter from iGOLDENLasers?

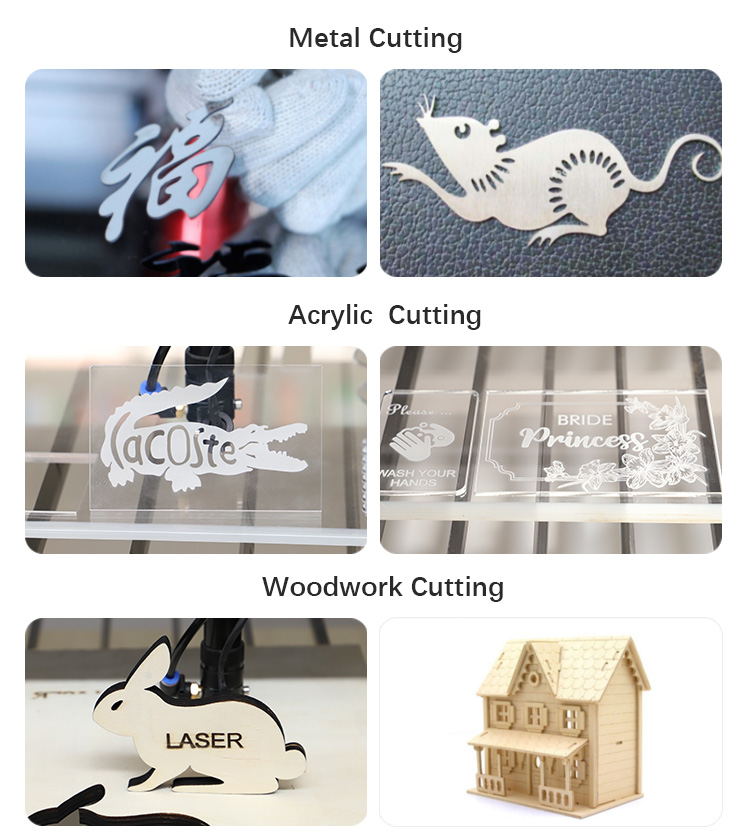

Our machines have been utilised in a huge range of industries, from compact modern CNC machines for schools and workshops to purpose built machines for complete production lines. With a wood laser cutter, you can drastically increase production whilst lowering costs. Our British design and manufactured wood laser cutting machines are of the highest quality, leaving a feather-free cut so there is no need for a 'post process' to sand the edge – a major advantage compared to other machines such as routers.

It’s important to understand that we do offer a wide range of wood laser cutting machines for different requirements, so if you’re unsure on the best system for your specific application, it’s best to contact a member of our team. That said, with any of our systems, you’re guaranteed a reliable wood laser cutter that marks and engraves most woods, as well as plywood and MDF, but they can also cut or engrave many other materials, including ceramics, stone, glass, card, paper and fabric.

For the full run down on the types of wood suitable for laser cutting and laser engraving, see the list below:

Alder

Balsa

Bamboo

Beechwood

Birch

Cedar

Cherry

Ebony

Fine wood

Genuine wood

MDF

Maple

Natural

Pine

Solid timber

Solid wood

VeneerAnd many more!

Having designed and manufactured wood laser cutters for a diverse range of clients, we have a strong understanding on our customers’ typical applications, and some of these include creating coasters, toys, wood inlays, gift box decorations and architectural models.

The laser machine is the general term for laser engraving machines, laser cutting machines, and laser marking machines. The laser machine uses its high-temperature working principle to act on the surface of the processed material, and at the same time draws patterns and texts required by customers based on the graphics input into the machine.

In the past, creating custom wood pieces involved the use of a saw, perhaps a hammer, chisel, and a lot of elbow grease. Today, 3d wood laser cutters and engravers are two of the most popular options in the industry due to the versatility, reliability and insane accuracy. Laser technology is used for virtually any category of woodworking: from architecture and furniture to toys and crafts.

Insofar as laser cutting is concerned, wood can be separated into two distinct groups:

Natural timber from various species of tree. For example, maple or cherry wood.

Man-made wood manufactured by bonding wood pulp, fibers or shavings. For example, MDF or plywood

How thick of wood can a CO2 laser cut through?

Multiple factors are at work here but generally speaking a CO2 laser with 50 watts of power is more than capable of cleanly laser cutting thru 1/4″ wood (in a single pass) and up to 3/4″ with 150 watts. Factors such as the speed of the laser and the type of wood being processed will alter a laser’s wood cutting ability. As an example, Cherry and Walnut can require up to 25% more cutting power compared to Maple. And solid oak often requires even more. We have a lot of experience with processing woods and have material processing charts you can use as a starting point.

All natural timbers can be cut by a CO2 laser at the 10.6µm wavelength. Limitations only apply with regard to thickness and the degree of charring that is acceptable to the customer.

Can any type of wood be cut and engraved with the laser?

Wood is an organic or natural material and is easily processed using a CO2 powered laser. However, factors within each type of wood will contribute to how the laser reacts such as the woods resin, content, and density and can dramatically effect the finished result. Soft woods including pines, cedar, or balsa wood will often require a reduction in laser power or increasing the laser head speed so as to prevent burn marks. On the other hand hardwoods need a higher laser power or slower speeds to effectively process.

Special versions of wood laser cutter are made for specific wood cutting applications such as, for example, laser cutting plywood for label dies. However, for the purpose of this article we are referring to a typical benchtop format laser cutter <100w.

For most industries laser cutting anything beyond 12mm natural timber and 9mm plywood produces an undesirable result because the feed rate (speed of cut) combined with optical limitations causes the wood to adversely burn.

When laser cutting wood the rate of laser fume extraction, particularly underside extraction and air assist delivered through the nosecone, can never be too much. When vaporised, wood produces a very dense fume that if not immediately evacuated from the cutting line will rise into the path of the beam and absorb laser power, significantly dropping the feed rate of the cut and in turn accelerating the degree of charring at the edge of the cut.

High amounts of debris from wood laser cutting machine can also contaminate laser optics causing them to fail prematurely and also cause HAZ (Heat Affected Zone), which is an undesirable staining to the edge and surfaces of the material.

In machines where the design of extraction is poor, surface HAZ can be minimised by first applying a low-tack, paper based tape to both surfaces of the wood. The tape acts as a masking barrier, attracting the contamination. After laser cutting the paper is removed and the wood surface underneath is clean.

Natural timber has a tendency to warp, which is challenging for a wood cutting laser as this causes the beam to defocus, producing undesirable results. Therefore, if the application calls for laser cutting of natural timber it is best to process the material as soon as possible after receiving it from the mill.

Man-made or engineered woods can contain resins that are actually designed to be fire retardant. This is unhelpful when trying to burn through the wood with a laser cutter!

Therefore, if the application calls for using a form of engineered wood it’s wise to be very selective about the exact type of material you use. For example, plywood is most commonly available in a WBP or exterior grade. The resins used to bond this type of plywood are among the least laser friendly and will resist the laser cutting process, accelerating HAZ.

Interior grade plywood, sometimes called white glue plywood, is among the most laser friendly plywood’s. Not as commonly available as exterior grade, interior grade should be used as a preference for laser cutting if the job specification allows it as the resins in the material will vaporise much cleaner.

An often overlooked aspect is that of the surface finish of wood prior to laser cutting. If the part to be laser cut is the finished item then the surface should always be sealed/finished before it is laser cut. This reduces HAZ and any HAZ present can be wiped off with a slightly damp cloth. If however the material is to be post processed, such as sanding for example, then pre-sealing the wood is not absolutely necessary as the HAZ will be removed during post processing.

At Laser Systems we manufacture a wide range laser, marking and engraving solutions ideally configured for laser cutting and laser engraving wood. Our experts would be happy to recommend which configuration best suits your application.

content is empty!