Views: 15 Author: Site Editor Publish Time: 2022-12-19 Origin: Site

In consideration of lots of users is still a beginner in laser engraving, so below is a comprehensive guide that will go over the basics of how laser engravers work, the different types available, and what you need to get started. So whether you’re just starting out or are looking for more information on using your laser engraver, read on!

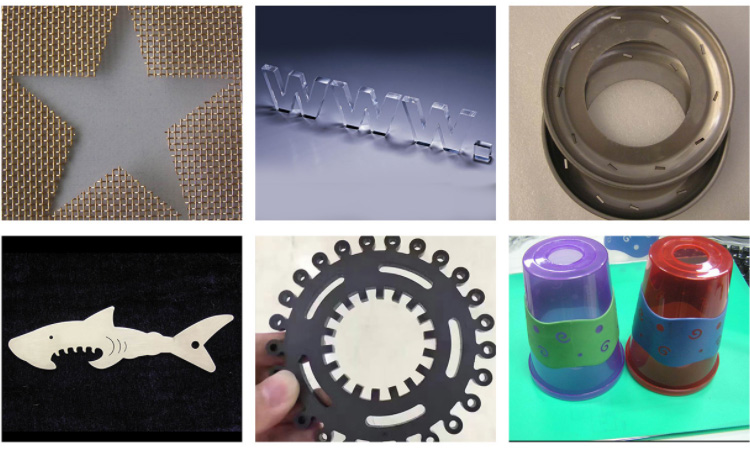

A laser engraver is equipment used to engrave permanent marks on surfaces. It etches anything, from wood, stone, marble, tile, cardboard, aluminium and even glass to create unique designs.

Laser engravers work by exposing a narrow laser to the material. The excessive heat of the laser causes the material to melt, burn and vaporize, resulting in a permanent abrasion-resistant engraving.

Moreover, the high precision of laser engraving equipment allows designing intricate details on materials without using multiple tools. Companies use laser engravers to etch serial numbers, logos in their products, but you can use it to carve your name or scenery on wood or metal.

This engraving technology works on different surfaces and materials to create stunning masterpieces with high value. As a result, a laser engraver has a wide range of applications, including:

Signage

Barcode creation

Designing awards and trophies

Creating electronic components and medical equipment

Crafting commemorative and decorative annotations

Types of Laser Engravers

There are three main types of laser engravers, including:

CO2 Laser Engraver: It involves using carbon dioxide beams to penetrate the material. However, it has a low-efficiency level; hence it’s ideal for engraving and cutting non-metal materials such as paper, fabric, leather, and wood.

Diode Laser Engraver: it becomes quite popular with hobbyists and makers. The diode in this laser is usually an optoelectronic device that converts electrical energy to light, leading to coherent light with high intensity used to engrave objects.

Fiber Laser Engraver: It produces strong laser beams by pumping an extremely intense level of light via fiber optic cables. Note that these cables are normally doped with ytterbium to release high-capacity energy in the form of photons.

How Does a Laser Engraver Work?

A laser engraver vaporizes materials, generating fumes and leaving permanent engraved marks. This equipment utilizes a laser beam that acts as its chisel, precisely incising marks on material by removing a substantial material layer from its surface. The edge that’s left behind will have a premium quality finish on its surface.

The effectiveness of using a laser engraver is because it can hit all localized areas with a high energy level. This normally leads to the generation of high heat needed for the process of vaporization. The right laser engraving process depends on:

The type of material being engraved

The vaporization process that’s ideal for engravement usually depends on the ability of the material to withstand temperature. Below is an example of vaporization temperatures in degrees celsius of different materials:

Zinc – 906

Lead – 1750

Aluminum – 2327

Copper 2595

Iron – 3000

content is empty!