Views: 12 Author: Site Editor Publish Time: 2022-12-26 Origin: Site

ATC CNC Router is manufactured using global state-of-the-art techniques with advanced engineering, workmanship, and built to last with all-steel construction and superior components such as precision linear bearings and rails. Key features are a 9KW(12HP) high-frequency automatic tool changer spindle with a 4-position tool rack, pneumatically retractable vacuum hood, and multi-zone vacuum t-slot table. The system includes Servo motors and controls with a handle controller.

Auto Tool Changer Principle:

The machine uses a cylinder power system to control the pushing and retracting of the tool magazine and is equipped with more than four sensors to repeatedly confirm the working environment to ensure the correct operation of the system. Compared with the traditional fixed tool magazine structure, the error tolerance rate is greatly improved, ensuring the service life of the tool magazine and the danger brought by operating errors. The increased tool magazine shell effectively prevents dust accumulation, reduces airflow, and plays a certain role in inhibiting tool holder oxidation.

The ATC feature allows our CNC routers to do the full job, even when different tooling is required to make different types of cuts, like cabinets and furniture, or where different bits are needed for roughing and finishing passes. Signs and complex 3D carvings are good examples of this. A machine equipped with an ATC can perform operations normally done on other pieces of equipment, eliminating the need for additional machines in the shop.

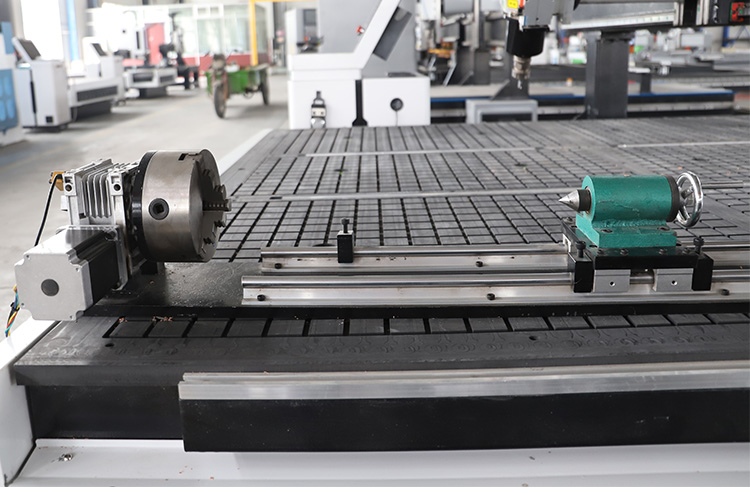

Based on ATC, adding a rotary attachment, can not only realize the processing of flat workpieces, but also the processing of three-dimensional workpieces and irregular workpieces. The rotary axis could be on the machine side, or the machine table; could be fixed on the machine, also could be moveable.

The 4th ATC CNC Router is multifunctional in one. It can not only realize flat and three-dimensional processing but also save time and space by automatically changing tools.

Linear automatic tool changer

The linear tool magazine can be placed under the gantry or behind the machine. The linear tool change usually could be support 4-10 pcs tool holder, with ISO 30 tool holder.

The following is the general process of tool change:

Tool change command> Confirm tool magazine retract> Reach tool change position 1> Tool Holder Lauch> Confirm tool holder push inposition> Loose tool holder> Loose tool holder confirmation signal> Reach tool change position 2> Clamp tool holder> Clamp tool confirmation signal> Tool holder retraction >Confirm tool holder retracted in place>Reached tool holder z height>Tool change completed

Machine Body

The Frame is the backbone of a CNC router machine, The ATC frame adapts wall steel square tube welded together, precision machined and stress relieved so that the foundation remains true and steady over the operational life of the machine. solid and not deformed. The lathe bed is processed by industrial welding, quenching, and tempering and then machined by the machining center. The professional strengthening rib structure (sturdy bed welding process) ensures the bearing capacity and stability of the bed, ensuring the rigidity of the bed and Geometric accuracy; After high-temperature tempering treatment to ensure the best strength and rigidity side arranged structure, heavy column, etc. Compared to ordinary machines, it has a better stability.

Positioning Cylinder

For the standard 1325, the positioning cylinders are usually distributed in 2 on the X-axis and 3 on the Y-axis. These pneumatic devices form an L-shaped right angle. Function: Position the plate to be processed, reduce the time of manual positioning of the plate, and improve the efficiency of plate feeding. After installing the positioning cylinder, it is possible to ensure that each sheet is placed in the same position, without repeating the definition of the workpiece origin to ensure the positioning accuracy, which is simple to operate and saves time. The main point is safety performance. The positioning of the cylinder is also controlled by the control system's program. It has a cross-border protection device. When the positioning shaft of the cylinder extends, the machine automatically stops working to prevent the spindle tool from cutting the cylinder or the cylinder shaft from damaging the tool. , Can avoid unnecessary losses in a limited way.

content is empty!