Views: 15 Author: Site Editor Publish Time: 2021-09-07 Origin: Site

Stone cnc machine integrates multiple advantages into one machine. It uses servo motors and ball screw. It adopts a servo system to realize X, Y, and Z axes linkage. The machine has the advantages of high precision and stable performance. Compared with traditional cutting machines, the efficiency is increased by 35%, and raw materials loss is reduced by 15%. The produced stone slabs are accurate in size and smooth in cut surfaces, machine is especially suitable for processing high-value and large-size marble and granite stone slabs.CN¥225,081.50 - CN¥385,854.00

1) Import high precision preloaded backlash ball screw, the movement is generated when clearance to reduce to the smallest.

2) Use the high quality brand drive, faster than the original model improves the nearly 2 meters.

3) Import guide rail, self lubricating block, make each direction force equal to ensure that the mechanical precision and strength.

4) Adopts the breakpoint memory way, to guarantee available in accident (broken knife) or the next day processing.

5) Unique multiple work piece processing origin preservation mode

6) Gantry mobile, strengthen mesa, durable, long time use deformation, better positioning accuracy Plate production not only make carving fine without jagged, basal level off is smooth and contour is clear, and cutting 2 cm organic glass also relaxed freely.

7) Machine body is welded steel tube or whole cast iron,it's up to you.

How to make the stone cnc machine for Granite not easy to rust?

1.It must be noted that the oil used for the X, Y, and Z three-axis polished rods is maintained.

2. The screw part must be wiped with butter; if the working environment temperature is too low in winter, the screw, polished rod, square rail or round rail should be washed and cleaned with gasoline first, and then oil is added, otherwise it will cause the machine The resistance of the transmission part is too large, which leads to problems such as the dislocation of the machine

3. The surface of steel parts, such as the ball screw, the hardened steel raceway of the rolling guide, and the surface of steel fasteners, should be rubbed with cloth or cotton dipped in butter every few days. Other parts should be frequently observed for weak rust. If there is any, it should be wiped off with a cloth dipped in engine oil and used as the focus of future rust prevention.

4. The surface of aluminum parts should also be wiped with a cloth dipped in butter every few days, or a layer of varnish can be sprayed. And often observe whether there are pits.

5. It is best to fill the cooling water tank with emulsified oil to prevent rust, and do not use clean water.

In recent years, stone carving, stone cnc carving machine , stone decoration and other industries are transforming at a rate of 30-46%. How to increase the extrusion molding speed, how to choose a stone engraving machine?

The choice of stone carving machine has the following five points:

1. The power of the engraving machine

The motor of the stone carving machine can be divided into several kilowatts and small power. The power of some engraving machines is only suitable for woodworking carving and soft width adjustment carving. Because the strength of stone is relatively large, its power base is 4.5-5.5kw. This kind of engraving machine can also be divided into two categories: one is the negative engraving machine through the engraving machine, which generally processes small billboards, and the other is that the cutting precision of the large surface is higher, and the negative film is generally more than 1 meter. The accuracy of the engraving machine is relatively poor.

2. Engraving machine motor

The motor of the engraving machine is an important part of the stone engraving machine. The motor directly damages the performance of the engraving machine. On the other hand, pay attention to whether the speed of the head motor can be adjusted. If possible, this means that the engraving machine has a wider range of engraving and more application areas. Because different engraving materials must use different engraving head rotations.

3. Assembly process

The stone cnc carving machine of several kilowatts stipulates that the internal hardware and machinery must be smooth and stable. The Audison stone carving machine adopts a heavy-duty pig iron lathe tool holder to ensure the reliability of carving and the precision of extrusion molding.

stone cnc machine Applicable materials

Marble, granite, Chaina black, bluestone, jade, ceramics, crystal, glass, plastics, chemical synthesis in organic glass, PVC board, bamboo, aluminum composite panel, metal, plastic and other meterials for line carve, 2D carving, 3D sharp bottom sulpture, 3D relief, cutting, chamfering of edge, cutting and drilling process.

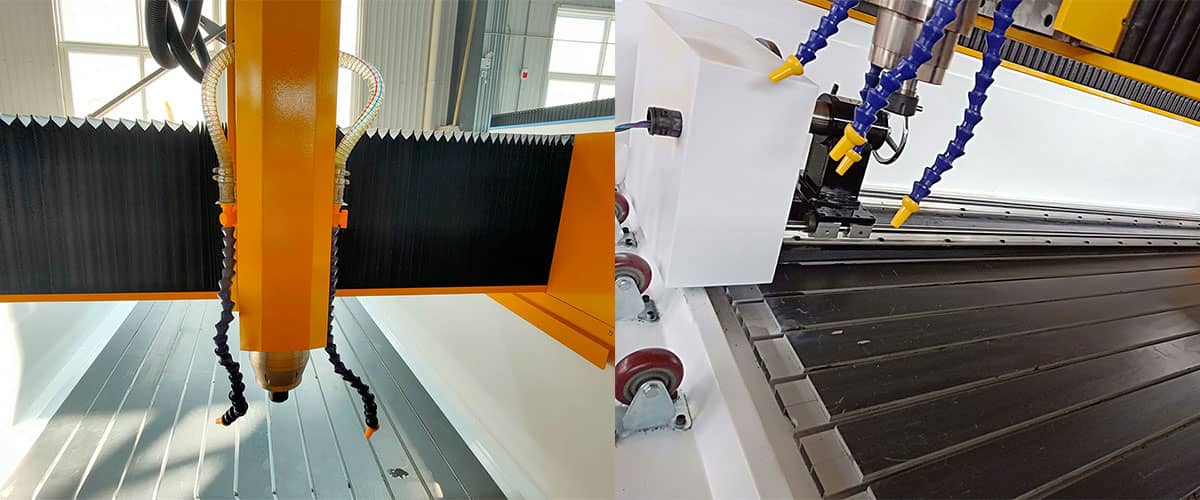

Detail pictures:

stone cnc machine Application

Suitable for stone, tombstone processing, advertising, decoration, arts and crafts industry etc..