Views: 16 Author: Site Editor Publish Time: 2021-07-01 Origin: Site

What is Wood CNC Machines ?

Stop looking elsewhere! IGOLDENCNC Wood CNC Machines supplier has collected them for you here! These automatic wood carving CNC routers are great tools for woodworking project makers. Our machine selection includes affordable Wood CNC Machines, mid-range Wood CNC Machines, and professional CNC wood CNC machine systems. If you’re stuck hesitating between machine models, feel free to contact us and know ourWood CNC Machines reviews anytime! (Tell us your budget, materials that need to process, size requirements, and we will give you the most suitable recommendation!)

Components of Wood CNC Machines CNC controller, CNC operating system, CNC software, T-slot table or vacuum table, motor, frame, guide rail, gantry, spindles, driver, ball screw, vacuum pump, power supply, rack, limit switch, pinion, and collet.

1.Assembling and locating the CNC machine on steady desk well.

2.Make sure that your computer has a USB port output.

3. Place the contral box in a ventilated dry place where there is no dust,no moisture

4. Connecting the control box with the CNC machine and you computer and make sure the plug will not come off.

5. Correctly connect the machine with the controller. Don't suspended the cable which connect the Spindle motor with axis(X,Y,Z,A).Otherwise, It willdamage the driver of the controller.

6. Correctly instal the Spindle motor and the heat pump. The heat pump should be covered completely in the water, then turned on the electric current to check whether the water-cooling system working well.

7. Installing a CNC control software and Drive such as the EMC2on your computer.

8. Fllowing our manual or guideline to set uo the software.

9. Before turn on the machine, please check all the cable and water- cooling system to make sure they are working fine.

10.You can enjoy making you dream with using our CNC machine now.

Features of Wood CNC Machines:

1.Adopt industrial heavy-duty structure design, combined with the finite element method calculation, annealing and destressing

strictly according to process requirements, thus to ensure the strength and rigidity of the machine body.

2.Standard configured with independent 6 zone matrix vacuum table with high strength (A1 model only 4 pc). Optimized partition

management, suitable for different size processing.

3.Adopt gantry transmission structure, to ensure fast speed and high efficiency.

4.Adopt Japan THK high precision linear rail with lubrication system, more wearable.

5.Configured with Delta Servo system, to ensure the transmission stronger and noise lower.

6.Independent controlling cabinet, separation of strong electricity and weak electricity to make the maintenance more convenient.

7.Configured with high performance Taiwan TECO inverter, speed control uniform and cutting edge smooth.

Learned what is a Wood CNC Machines, But why we need it? What are the Wood CNC Machines advantages? Compared with simple hand-craft:

1、High cost performance. Processing requirements can be met without high procurement and training costs. This type of wood engraving machine can help users save 30% purchase cost. It also can be used as Wood CNC Machines especially for MDF, wood panel cutting.

2、Wide range of applications. Wood CNC Machines: can be widely used in advertising industry, craft industry, mold industry, electronics industry, construction industry, printing and packaging industry, wood industry, decoration industry, tombstone industry, etc. Extensive processing materials. CNC wood router can meet the processing of most of non-metal materials like acrylic, PVC board, hibiscus board, two-color board, wood board, density board, marble, fire board, rubber board, glass, crystal.

3、High degree of automation. Compared with the traditional processing methods in the past, the processing efficiency of the Wood CNC Machines ,has been increased by 50%, which brings greater profit margins to users.

Some Wood CNC Machines are specialized for cabinetry and have many drills that can be programmed to come down separately or together. The drills are generally spaced 32 mm apart on centres - a spacing system called 32 mm System. This is for the proper spacing of shelving for cabinets. Drilling can be vertical or horizontal (in the Y or X axis from either side/end of the workpiece) which allows a panel to be drilled on all four edges as well as the top surface. Many of these machines with large drilling arrays are derived from CNC point-to-point borers.

| X, Y Axis Working Area | mm | 1300*2500/ 1500*2500/1500*3000/ 2000*3000/ 2000*4000 |

| Z Axis Working Height | mm | 200 |

| Positioning Accuracy | mm | 0.05 |

| Re-positioning Accuracy | mm | 0.02 |

| Body Structure | Welding Body | |

| X, Y Axis Structure | Linear Guide Rail, Gear Rack | |

| Z Axis Structure | Linear Guide Rail, Ball Screw | |

| Max. Running Speed | mm/min | 50000 |

| Max. Working Speed | mm/min | 20000 |

| Spindle | kw | 4.5kw Air-cooling Spindle(Optioned) |

| Spindle RPM | rpm/min | 24000 |

| Working Voltage | V/Hz | AC 220V/ 380V, 50-60Hz |

| Machine Weight | kg | 1400/1700/1900/2200/2500 |

| *Some specifications support customization, please contact us | ||

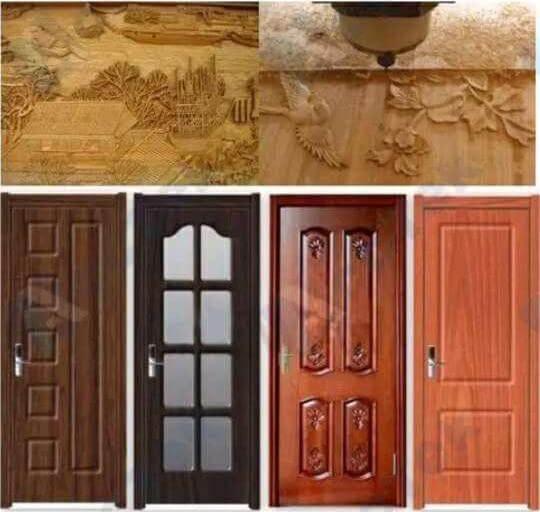

Sample display of CNC wood router:

content is empty!