Views: 6 Author: Site Editor Publish Time: 2021-09-15 Origin: Site

The 4 axis cnc router has all the same axes of a 3-axis router plus the additional A-axis that rotates the spindle around the X-axis up to 180 degrees during the cutting process.

This rotational axis allows cuts to be executed on multiple sides of the workpiece without resetting, while a 3-axis router can only perform cuts to one side of the same piece at a time. 4 axis cnc router are the preferred method for advanced, intricate cuts and carvings like those often seen in furniture, musical instruments, cabinetry, and more.

A 4 axis cnc router wood has a lot of advantages. Here are the top five advantages that make a4 axis cnc router the first choice for various industries:

1. Increased Effectiveness of Production: One can program the 4 axis cnc router to lower human interference in a particular manufacturing process. This helps reduce production time, thus ensuring increased production effectiveness.

2. Simplifies work: The processes that an operator performs manually with a conventional machine take a lot of time and efforts. These processes can be programmed using a 4 axis cnc router thus, simplifying the work for the operator.

3. High Precision: A 4 axis cnc router is capable of producing precise work pieces consistently. Once the programming controls are confirmed, the 4 axis cnc router produces thousands of pieces, in a short period of time.

4. Flexible Processing: As the processes are programmed, a 4 axis cnc router is flexible. You can run a key program for one piece, save it, and then recall it again when the piece is required to be cloned.

5. Easy to Set-up: A 4 axis CNC machine is easy to setup. This helps you save time, and allows you to meet deadlines efficiently.

Scope of Application

4 axis cnc router applications

Woodworking industry: door, furniture, loudspeaker boxes, musical instruments, etc.

Advertising industry: 3D billboards, signage, medals, badges, traffic signs, letter punches, logos, etc.

Model industry: various 3D models, landscape models, exhibition models, architecture models, car models, etc.

Sculpture: human sculptures, character sculptures, fauna and flora sculptures, etc.

Film industry: movie props, activity props, etc.

Other industries: cutting and curving the 3D surface and outline of gift wrapping, tabletops, sports equipment, wood products, etc.

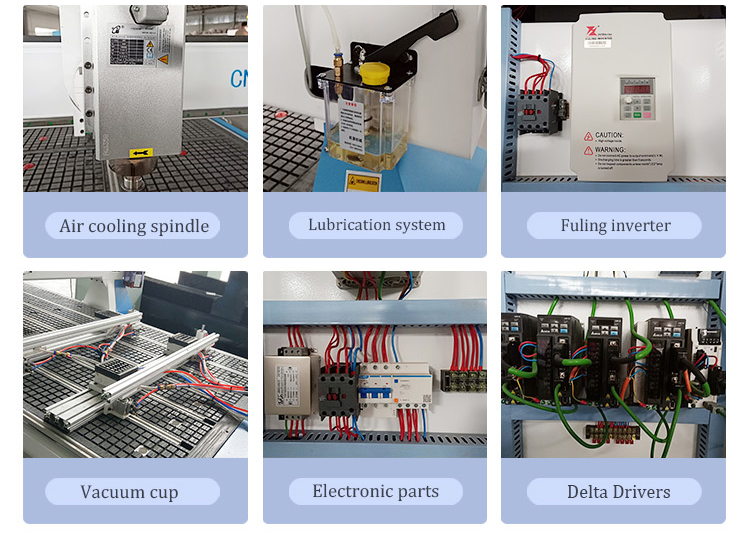

Italy Electro spindle

One of the most important parts of any wood machine is the spindle system. We only use Italian HSD Spindles on our ATC CNC Router machines, with unrivaled speed and performance you know you have made the right choice. Our ATC's come complete with 9.6Kw rated units.