Views: 27 Author: Site Editor Publish Time: 2021-09-28 Origin: Site

EPS Foam CNC Machine with 3 axis for normal cutting and carving, 4 axis swing head for mold carving and cutting, 4th axis rotary for cylinder carving and cutting, now the 3 axis CNC foam router cutting machine for sale at cost price.

First, Computer-Aided Design (CAD) software is used to create and optimise a design based on the object the foam packaging is intended to hold. Once this design is finalised, Computer-Aided Manufacturing (CAM) software is used to turn the dimensions of the design into detailed numerical instructions for the CNC machine to understand. The file information must also be converted into a language that CNC machines understand. This language is called G-code.

The G-code essentially tells the machine what operations to perform, such as the dimensions and depth of a cut, as well as the toolpath to follow. Once the CNC machine has received the G-code and has been set up with the appropriate router bit and material, it is then time to cut the final product out of foam. Precise mechanisms and sharp blades enable the operator to cut any shape out of the foam, as long as the thickness corresponds to the thickness of the material.

EPS Foam CNC Machine Features:

1. EPS Foam CNC Machine's effective working area is 1300mm*2500mm*600mm(XYZ).

2. Heavy Hard Steel Lath Body, keep the machine's working High stability. Whole machine is welded with seamless steel structure, dealing with Time-treatment, the stability is excellent, never to be deformed.

3. Taiwan TBI high-precision and bigger ball screw. Original bigger Taiwan HIWIN straight square guide rail to make sure the machine’s working high-speed and high-efficiency.

4. The mold making machine adopts gantry movement, it can process any kinds of materials freely.

5. Well compatibility: CAD/DAM designing software e.g. Type 3/Artcam/Castmate/Wentai etc.

6. Dust proof design keeps the machine work in a clean condition, good for the machine and maintenance.

7. Has the function of recarving after break point and power failure.

8. Has the function of forecasting process time.

9. DSP control system can completely work off-line and do not take any computer resources.

10. Perfect oil-inject system makes maintenance much easier.

11. Tools' specification: You can choose different diameter and length tool according to your processing .

Advantages of Our EPS Foam CNC Machine:

• The machine base is welded by a high-rigidity steel structure, thick-walled and multi-ribbed, through multiple stress-relief processes. EagleTec cnc router foam cutting machine owns significant inflexibility.

Adopting the new generation of the latest absolute value servo drive system from SYNTEC, with the bus control CNC system from the same company, it is prior to ordinary servo on the performance of machining accuracy. It is a real closed-loop system, which ensures diagnostics of technical parameters of operation of the drive assemblies and units during machine operation for the purpose of no-failure operation of machine under the predetermined process conditions.

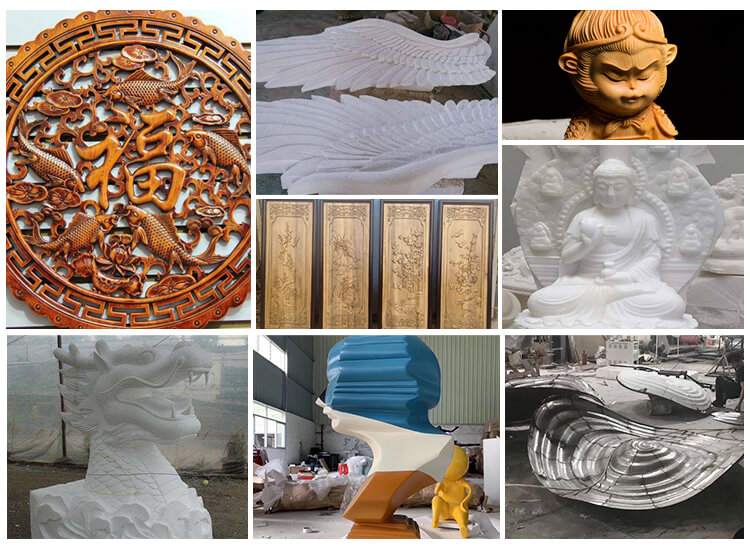

Scope of Application

EPS Foam CNC Machine Applicable materials:

Wood, EPS (Any kind of Foam) and non-metallic materials.

1. Mold industries:

sculpture various large non-metallic mold can be particularly suitable for any kind of Foam (EPS) mould, wooden ship model,wooden model aviation and other wooden mould.

2.Foam industry: Can carve and cut on any kind of Foam (EPS) , do 2D and 3D dimension processing.

Cubic sculpture Field: used for making big size non-metal sculpture, City Plaza sculpture, Advertising sculpture, Hotel sculpture, etc..

Processing effect:

It can manufacture the following effects: engraving, cutting, milling ,drilling, relief, shadow, enchasement and so on.