Views: 21 Author: Site Editor Publish Time: 2021-09-03 Origin: Site

Laser cleaning machines are finding great applications in the industry today. It is often seen that rust, grease, and other such substrates form a layer with time over metals and non-metallic products. And with increasing time the laser rust cleaning and metallic parts cleaning technologies have evolved.

laser cleaning machine is a new generation of high-tech surface cleaning products. It is easy to install, control, and implement automation. With Simple operation, switching power supply, open the device, then it can be achieved cleaning without chemical reagent, medium and water washing, it has many advantages of the focus adjustment manually, joint surface cleaning, higher cleaning surface cleanliness, it also can remove the surface of resin, grease, stains, dirt, rust, coating, paint on objects.

The first Laser Cleaning Machine For Metal with high fiber laser in China.

Substrate non-contact cleaning, without damage.

High precision cleaning, good precision of position cleaning,selective washing.

Without any chemical cleaning fluid and no consume materials,safe and environment protecting.

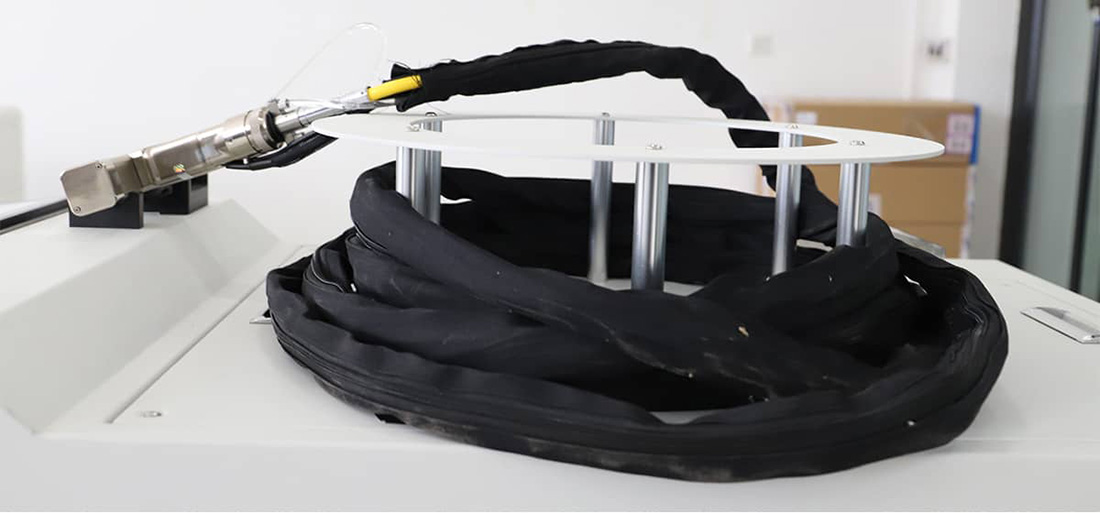

Simple operation,hand-hold clean or with a mechanical hand to clean.

Good cleaning effect and save time.

Laser cleaning system is stability, almost no maintenance.

Advantages of laser cleaning machine:

1.non-contact cleaning, does not damage the part substrate.

2.precise cleaning, can achieve precise location, the exact size of the selective cleaning.

3.laser-cleaning-machine without any chemical cleaning fluid, no supplies, safety and environmental protection.

4.simple operation, power can be hand-held or with the robot to achieve automated cleaning.

5.cleaning efficiency is very high, save time.

6.laser cleaning system is stable, almost no maintenance

Touch screen settings panel

content is empty!