Laser Rust Removal Cleaning Machine Description:

The laser rust removal cleaning machine is assembled. It meets the cleaning requirements of complex shapes and fine positioning in the industrial processing field, and achieves higher cleanliness cleaning effects and lower overall cost production benefits.

Handheld Fiber Laser Cleaning Machine Advantages:

●Support process library storage;

●Light spot adjustable (0.5-5) mm;

●Invite professional international laser friends to translate, and at the same time have received nine translations from Chinese, English, Korean, Japanese, Russian, Traditional, French, Spanish, and Israeli

languages;

●The system monitors the running status from time to time, monitors and collects the running status of lasers, chillers, and control panels;

●With temperature monitoring;

●Light weight, small size, ergonomic design and comfortable grip;

●Safety lock touches out light;

●Easy to operate, very low requirements for operators;

●Strong anti-interference;

●Fully sealed structure with built-in water and air paths;

●Configured with independent research and development control system;

●10m cable length, can be customized up to 1km

Rust Removal Laser Cleaning Machine Features:

★ Non-contact is cleaning, does not damage the parts substrate;

★ Precise cleaning, can achieve selective cleaning of precise position and precise size;

★ No need for any chemical cleaning fluid, no consumables, safe and environmentally friendly;

★ Simple operation, just power on, can be hand-held with the robot to achieve automatic cleaning;

★ High cleaning efficiency, save time;

★ The laser cleaning system is stable and requires almost no maintenance.

Laser Rust Removal Machine Parameters:

| Laser Wavelength | 1064nm |

| Laser Power | 1000W/1500W/2000W |

| Fiber Length | 8-10m(15m Optioned) |

| Scanning Width | 10-80mm |

| Voltage | 220V,50/60HZ |

| Cooling Method | Water-cooling |

| Working Temperature | 5-45℃ |

Portable Handheld Fiber Laser Cleaner Configuration:

Cleaning machine laser head:

High cleaning cleanliness It can accurately locate and clean contact cleaning, protect thesurface of brittle materials,and effectively remove micron-level pollution particles; green and environmentally friendly, no consumables are required.

This not only means that laser cleaning is effective, but the cleaning process is environmentally friendly.

In addition, it does not use chemical cleaning agents, thus avoiding the damage caused by chemical corrosion to the material.

The high-intensity light pulse generated by the laser that calculates and sets the threshold value forms an interaction between the short-pulse laser and the contaminated layer, resulting in a photophysical reaction.

The beam is absorbed by the contaminated layer on the surface to be treated. The absorption of large energy forms a rapidly expanding plasma (highly ionized unstable gas), which generates shock waves.

The shock waves turn pollutants, oxides, etc. into fragments and gases and are removed to complete the cleaning.

Laser Source

The laser adopts water-cooled heat dissipation and rack-mounted chassis design.

It has many advantages such as high electro-optical conversion efficiency, low energy consumption, compact structure, adjustment-free maintenance, and easy integration for customers.

It is industrial laser welding and other Ideal light source for application.

S&A Chiller

The cooling capacity is up to 1400W, and environmentally friendly refrigerants can be used;

Small size, long life and durable, easy to operate;

The temperature control accuracy can reach ±0.3℃;

The intelligent thermostat has two temperature control modes, which are suitable for different use occasions; it has a variety of settings and fault display functions;

With multiple alarm protection functions.

Touch screen settings panel

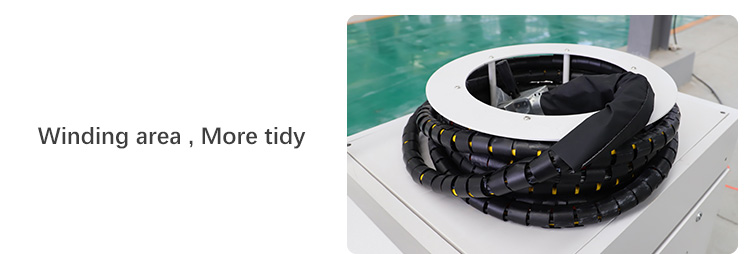

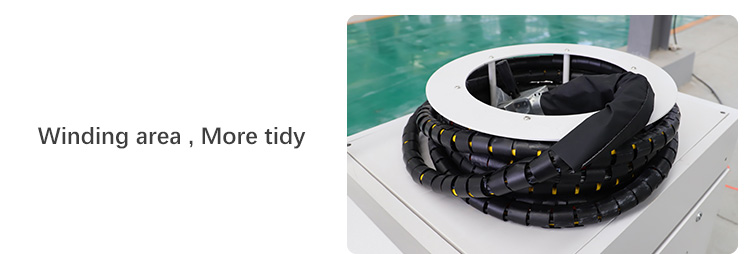

Winding area , More tidy

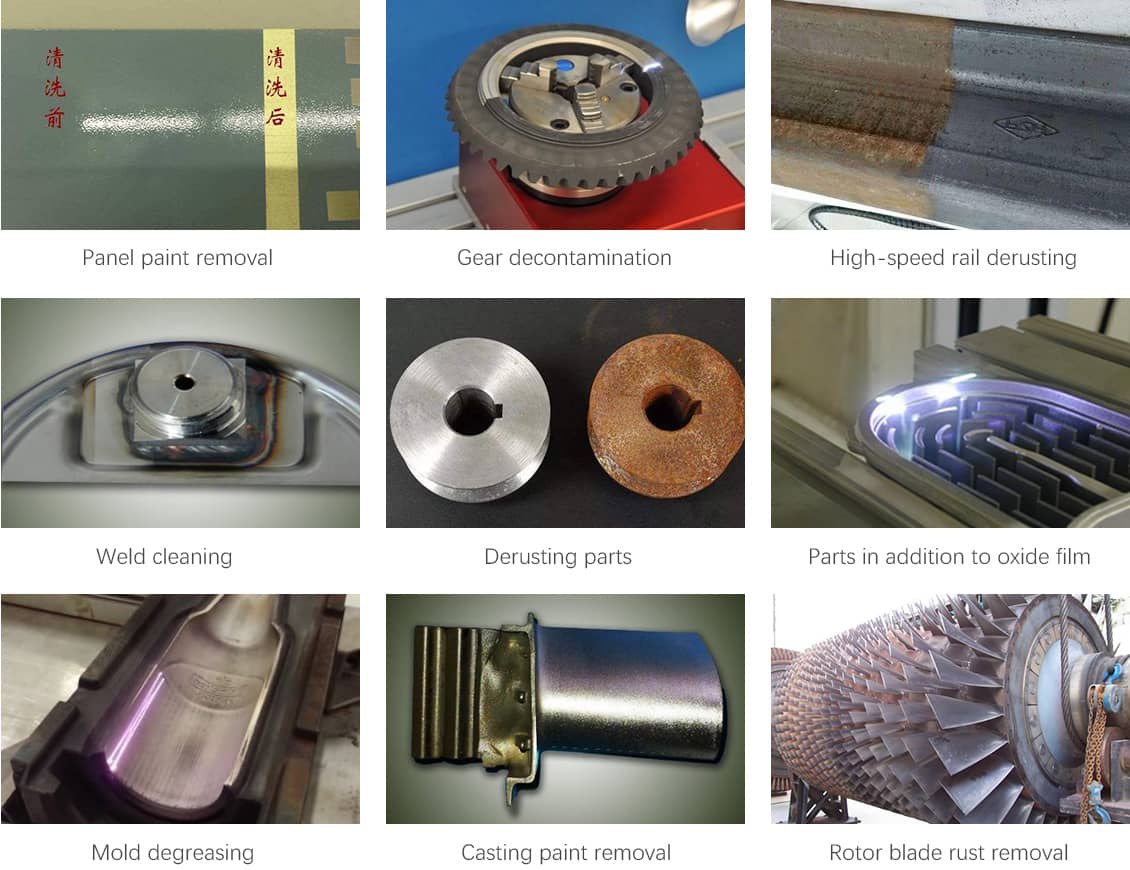

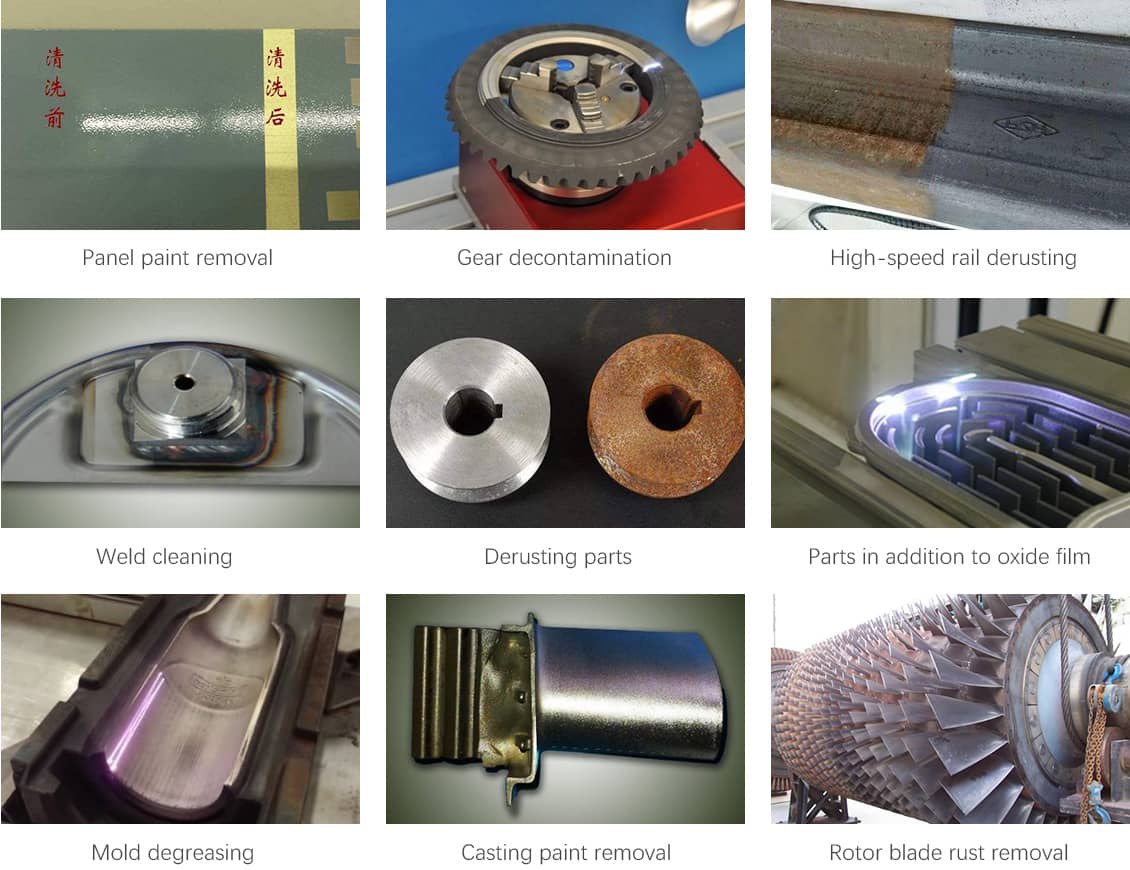

Fiber Laser Cleaning Machine Applications

Application Field

1. Rust removal from metal surface.

2. Paint removal from metal surface.

3. Clad layer and coating removal.

4. Oil fouling, blot, and dirt cleaning.

5. Metal weld discoloration removal.

6. Stone surface cleaning.

7. Rubber mold damage-free cleaning.

Application Industry

Manufacturing plant, construction works, machinery repair shops, advertisement, energy & mining, building material shops, ship industry, auto parts, rubber mold, high-end machine manufacturing, tire molde track, environmental protection industry.

iGOLDENCNC Factory View

Customer Visiting

iGOLDENCNC Service

| Pre-sales |

| > Free pre-sale consultation |

| > Free sample testing |

| > Professional CNC solutions |

| > Customer reception |

| > Fast delivery within 7 days(Available in stock) |

| > Customized machines delivered within 30 days |

| After-sales |

| > 2-year warranty |

| > Fast feedback and after-sales service in 12 hours |

| > Fast spare parts and technical assistance |

| > Free training services |

| > Special design, customized, OEM order |

English

English