Views: 14 Author: Site Editor Publish Time: 2021-11-18 Origin: Site

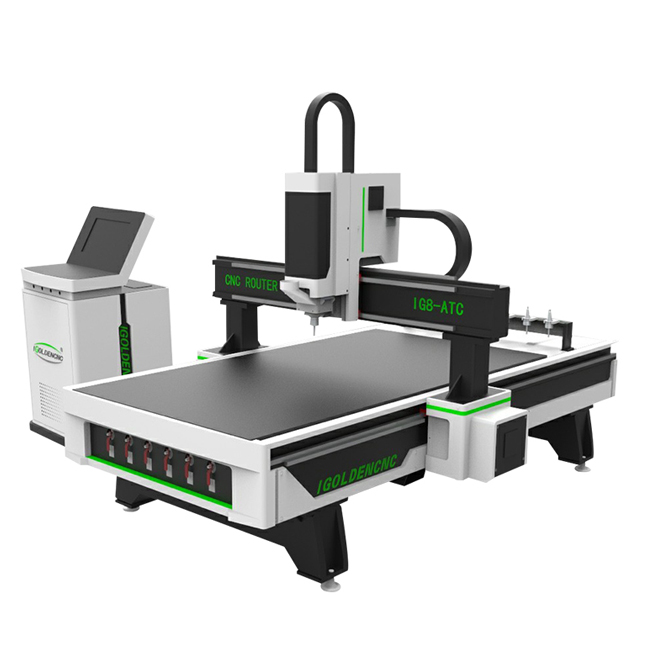

Increase precision and elevate your performance quality with IGOLDENCNC’s 3 Axis CNC router wood. These powerful and efficient machines are designed to handle even the most demanding production requirements. Made with world-class mechanical and electrical components as well as innovative technologies, these CNC routers reliably provide precise cuts and a perfect finish. Our 3-axis CNC router tables are highly adaptable and versatile, and they can easily be supplied with dual heads.

1. Maintain a good external environment for the machine

(1) Ensure the temperature of the operating workshop, especially in the winter, it is better to let the machine to reach room temperature.

(2) Check the applicable temperature of the fueling standard, at least to the minimum temperature.

(3) When the machine is not in use, if the room temperature is lower, the water in the tank should be poured out to prevent cracking of water tanks and water pipes. Although the influence of temperature on the CNC router machine is not very big, because many operators add butter to the screw and forget to clean up in winter, which makes the machine hard to run when it starts up. The temperature in some workrooms is very low. Although the oil is added, it can still be frozen.

(4) The humidity in the operation room should not be too high, otherwise, the electrical accessories of the machine are easy to worn out.

(5) CNC router machines cannot be installed in places with high humidity, dust, and pollution, otherwise, the performance of electronic components may be degraded and will cause poor electrical contact or short circuit faults. So if the environment of the CNC machine is not good, it will directly affect the normal operation of the machine.

(6) Electromagnetic interference in the operation room must be noted, if the interference is too large, it is easy to affect the machining accuracy. And it should be kept away from the equipment with high vibration to avoid interference.

2. Keep the CNC machine clean

(1) Every time the work is done, sweep and clean the table in time. Blow away the dust on the machine with an air gun! A lack of cleaning could lead to a buildup of dirt and debris. Besides, some debris can get into the lubrication system, so that stop the machine from working. Wiping down your machine daily will also keep the wood chips from building up in damage.

2) Clean up the chips around the guide rail and the linear bearing guide blocks to prevent the machine from jamming due to debris interference when it is running.

(3) Regularly clean the lead screw to prevent foreign objects from sticking on the lead screw. The screw is very important in the equipment. It determines the accuracy of the machine and also it plays an important role in the transmission process.

(4) Clean the industrial control box regularly, dust is the biggest killer of the circuit board. When the board is too dirty, it may cause a short-circuit fault. After each use of the machine, pay attention to cleaning, be sure to clean the dust on the platform and the transmission system.

(5) Filters should be checked and cleaned on a regular basis and replaced if necessary. When the filter is too dirty, there may be cause poor heat dissipation and malfunction.

(6) Cleaning your tool holders and collets and spindles are also important. They must be rustproof and clean.

(7) Check the surface of the spindle. You can wipe it with a clean soft cloth.

3. Regular lubrication

CNC machines need to be regularly lubricated to function properly and prevent premature wear. Each of these components such as the spindles, the lead screws, the guide rails, bearings, tool holder and sliders require regular and correct lubrication to slow down the wear speed. Please be sure to follow the manufacturer’s recommendations and use grease or oil. Improper lubrication can lead to machine parts sticking or not moving as smoothly as they should and even cause more serious problems.

(1)First, clean the guide rails and lead screws. Use a rag to clean the oil and material debris on the guide rails and the lead screws. If the temperature is low, add oil to the rails and lead screws, preferably antifreeze oil.

(2)The refueling cycle is twice a month.

(3)If the machine is not used for a long time, it should be refueled regularly to ensure the flexibility of the transmission system.

(4)After the oil is added, move slowly back and forth to ensure that lubricating oil can be evenly applied to the guide rail and the lead screw.

(5)Regular (weekly) lubrication of the transmission system (X, Y, Z three axes).

4. Check your computer regularly

Computer abnormalities can also cause a lot of problems, especially for the computer connected to a CNC router machine.

5. Cooling water for spindle motor

(1) Cooling water is very important for the water-cooled spindle motor. If the cooling water is too dirty, it will cause serious damage to the motor, so ensure that the cooling water clean. And the water spindle motor must not be dehydrated, and the cooling water should be replaced regularly to prevent the water temperature from being too high. In winter, if the working environment temperature is too low, the water in the tank can be replaced with antifreeze.

6. Follow Manufacturer's regular maintenance schedule

The manufacturer can provide manual which tells you when and how to maintain your machine. So please read it carefully and follow them strictly. This helps to identify potential problems before they become breakdowns, especially for inexperienced operators.

7. Inspection Check whether the moving part of the machine (drivers and motors) and the fixing screws are firm and reliable every month. If any lose connection, tighten the screws.

8. Have quick-wear parts on hand.

Keeping some easily damaged parts such as CNC router bits, CNC tool holder clips, collets, in-stock can save much time and extra shipping cost. You don’t need to wait for spare parts shipment and delivery. Just find them in your warehouse and replace them! Also, these spare parts don’t cost you too much. Start with a CNC router parts list and find a reliable parts provider.

3 Axis CNC router Features:

1. 3 Axis CNC router aluminum can automatic tools changer, Which can meet the processing needs of multiple processes at the same time.

2 With 4 pcs 4.0kw China best brand HQD air cooling spindle, high precision, long life, low noise and stable operation.

3. Automatic dust suction device, automatic pushing, automatic feeding assistance.

4. It with Automatic tool sensor, when working it can save time and increase efficiency.