| Availability: | |

|---|---|

Machine Advantages

The industrial heavy-duty seamless welding structure design is adopted, and the finite element method is used to calculate the reverse deformation of the welding structure. The excellent strength and rigidity are ensured through the heat treatment of the fuselage.

Adopt fixed column frame gantry, table moving transmission mode, make the equipment more stable, less vibration.

Multi point touchdown can adjust the foot of the machine, which is convenient to adjust the balance of the machine.

Taiwan's high-precision linear square guide, and imported high-precision ball screw, higher precision.

Equipped with mature NCStudio control system to ensure that the machine tool operates at high speed, fine without saw tooth ripple, smooth bottom plane and clear contour.

High frequency, high power water-cooled spindle, low noise, high torque, low jump rate, high cutting efficiency, high brightness products.

The vacuum adsorption platform is equipped as standard, and the table adopts partition control, which can adsorb different materials of different sizes to meet various processing requirements.

Independent control cabinet, strong and weak current separation, more convenient maintenance.

Parameter Configuration

Model | IG-1325 |

Bed structure | G1 bed, G1 column |

principal axis | New 5.5kW water cooled spindle |

Drive | leadshine 850W servo |

Reducer | SHIMPO |

System | NCStudio 95A |

Cabinet | Independent computer cabinet |

Guide | Taiwan HIWIN 25 guide rail |

Feed height | 200mm |

Mesa | Vacuum adsorption absorbable and clamping table |

Rack | new moon |

Vacuum pump | 7.5kW water cooling vacuum pump |

Vacuum cleaner | 3KW double tube dust collector, three axis dust-proof |

Scope of Application

Woodworking industry: woodworking engraving machine, photo frame cutting, wave board processing, wooden door production, MDF, violin arc surface production, solid wood furniture carving, solid wood art mural carving, paint-free door carving, cabinet door, craft wood door, paint-free door, screen, auxiliary processing of computer desks and panel furniture products;

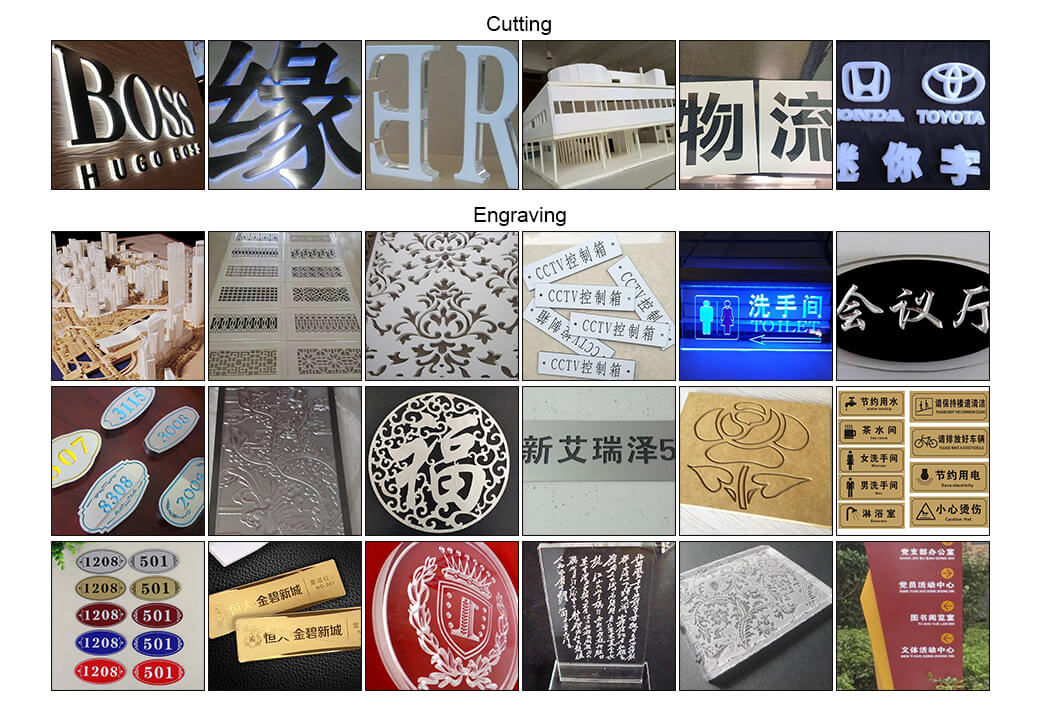

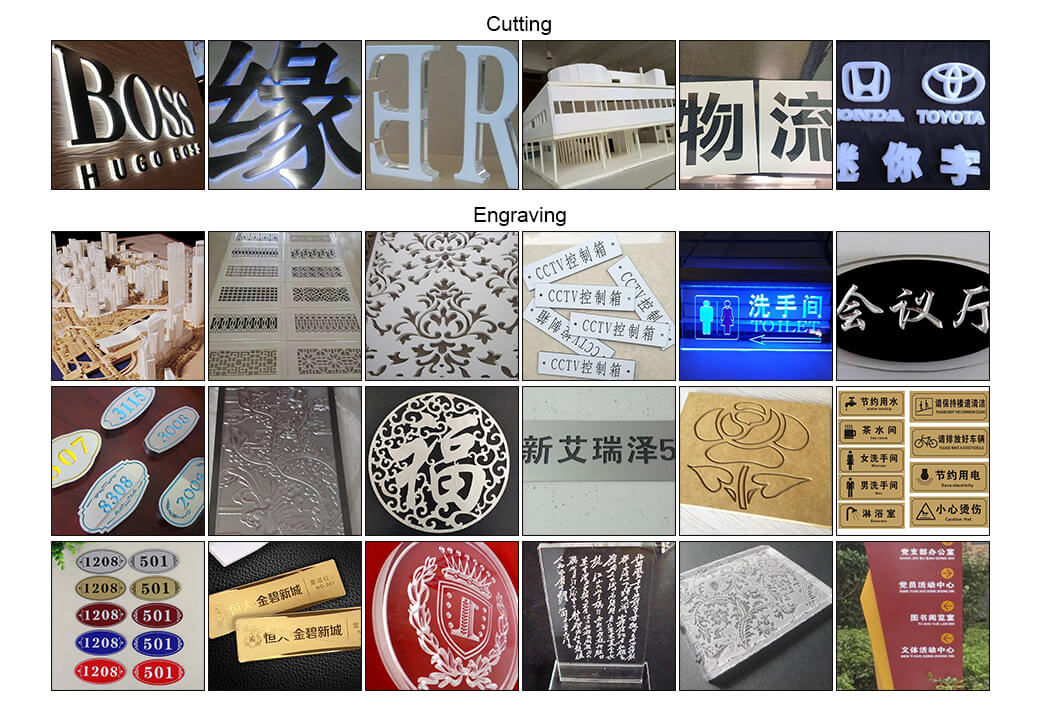

Billboard industry: large-character cutting, sign making, cutting PVC, crystal plate, acrylic, aluminium plate engraving and cutting, led / neon groove, hole-shaped literal cutting, plastic light box mold making;

It can also be used for the processing and production of various badges, department cards, architectural models, rulers, small metals, wooden molds, and reliefs.

About Us

Shandong iGolden CNC Technology Co., Ltd. is a R&D,manufacturing,sales integration company that specializing in cnc router, laser engraving and cutting machine, plasma cutting machine, cutting plotter,etc.The main configuration all adopt top parts which imported from Italy, Japan,Germany, etc. And welcome to visit us for more choices.

FAQ:

1.What's the working area of the acrylic carving machine?

The standard working area of acrylic carving machine is 1300*2500mm, but we can provide customized size as your requirements.

2.Which kind of materials is available for the acrylic CNC router machine?

Not only acrylic, but also wood, pvc, aluminum, copper and other materials.

3.What kind of work is the CNC machine suitable for?

Engraving and cutting of acrylic characters, luminous characters, neon trough characters and plastic light box molds in the advertising industry, 3D processing, etc.,

Machine Advantages

The industrial heavy-duty seamless welding structure design is adopted, and the finite element method is used to calculate the reverse deformation of the welding structure. The excellent strength and rigidity are ensured through the heat treatment of the fuselage.

Adopt fixed column frame gantry, table moving transmission mode, make the equipment more stable, less vibration.

Multi point touchdown can adjust the foot of the machine, which is convenient to adjust the balance of the machine.

Taiwan's high-precision linear square guide, and imported high-precision ball screw, higher precision.

Equipped with mature NCStudio control system to ensure that the machine tool operates at high speed, fine without saw tooth ripple, smooth bottom plane and clear contour.

High frequency, high power water-cooled spindle, low noise, high torque, low jump rate, high cutting efficiency, high brightness products.

The vacuum adsorption platform is equipped as standard, and the table adopts partition control, which can adsorb different materials of different sizes to meet various processing requirements.

Independent control cabinet, strong and weak current separation, more convenient maintenance.

Parameter Configuration

Model | IG-1325 |

Bed structure | G1 bed, G1 column |

principal axis | New 5.5kW water cooled spindle |

Drive | leadshine 850W servo |

Reducer | SHIMPO |

System | NCStudio 95A |

Cabinet | Independent computer cabinet |

Guide | Taiwan HIWIN 25 guide rail |

Feed height | 200mm |

Mesa | Vacuum adsorption absorbable and clamping table |

Rack | new moon |

Vacuum pump | 7.5kW water cooling vacuum pump |

Vacuum cleaner | 3KW double tube dust collector, three axis dust-proof |

Scope of Application

Woodworking industry: woodworking engraving machine, photo frame cutting, wave board processing, wooden door production, MDF, violin arc surface production, solid wood furniture carving, solid wood art mural carving, paint-free door carving, cabinet door, craft wood door, paint-free door, screen, auxiliary processing of computer desks and panel furniture products;

Billboard industry: large-character cutting, sign making, cutting PVC, crystal plate, acrylic, aluminium plate engraving and cutting, led / neon groove, hole-shaped literal cutting, plastic light box mold making;

It can also be used for the processing and production of various badges, department cards, architectural models, rulers, small metals, wooden molds, and reliefs.

About Us

Shandong iGolden CNC Technology Co., Ltd. is a R&D,manufacturing,sales integration company that specializing in cnc router, laser engraving and cutting machine, plasma cutting machine, cutting plotter,etc.The main configuration all adopt top parts which imported from Italy, Japan,Germany, etc. And welcome to visit us for more choices.

FAQ:

1.What's the working area of the acrylic carving machine?

The standard working area of acrylic carving machine is 1300*2500mm, but we can provide customized size as your requirements.

2.Which kind of materials is available for the acrylic CNC router machine?

Not only acrylic, but also wood, pvc, aluminum, copper and other materials.

3.What kind of work is the CNC machine suitable for?

Engraving and cutting of acrylic characters, luminous characters, neon trough characters and plastic light box molds in the advertising industry, 3D processing, etc.,

content is empty!