Views: 12 Author: Site Editor Publish Time: 2022-02-19 Origin: Site

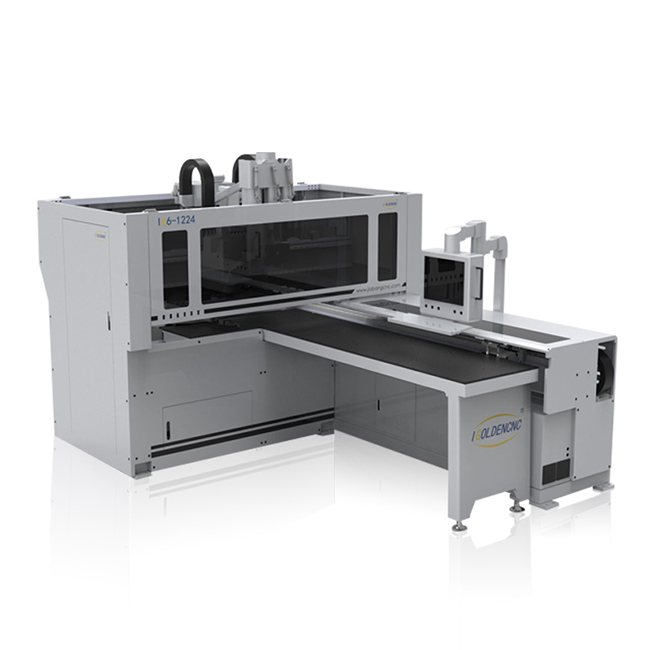

This is a high-end Automatic CNC drilling machine for panel furniture, which has the advantages of high processing efficiency and high degree of automation. Through wireless code scanning with automatic sorting function, automatic positioning, and automatic loading processing, it can realize six-side position processing and front and back groove processing at a time.Drilling machines are some of the simplest and most accurate machine tools. The drilling machine for wood is made up of a spindle that imparts rotational movement onto the drilling tool which then drives it into the workpiece.

Greatly improve the processing capacity and production efficiency by shortening the auxiliary working time. In addition, it reduces the number of traditional machine tools, saves the number of operators and reduces the floor area of the workshop.

Maintenance Procedures

Test lubricant frequently– Lubrication reduces friction around moving parts. Scheduling regular lubrication extends the drilling machine productive life. It is also important to check that you use the right lubrication.

Check for wear and tear– Vibration, friction, high temperature and shock contribute greatly to the breakdown of drilling machines. Checking for wear and tear allows you to detect and replace faulty parts as soon as they are noticed.

Clean the machine– Drilling machines have many seals and filters. Regular inspection ensures they are in working condition. Filters should also be changed regularly, and breathers kept clean to prevent creation of a vacuum which might suck contamination into the cab. Workers using the machine should also ensure all the holes in the machine are cleaned.

Sharpen the drilling components– Drilling machinery that has sharp, cutting, and slicing components must be sharpened. Dull cutting components compromise production and reduce efficiency.

The sharpness of a machine part also affects the shape and accuracy of the materials that are cut. Ensure all drill bits, end bills, precision cutters, and lathe tools are kept sharp.

Check alignment specifications– drilling machine for wood often have multiple components. Losing alignment can greatly affect the quality of work. You can check alignment by performing a test job and subsequently measuring the resulting parts. If the specifications are inaccurate, you will need to realign the machine.

Good records of maintenance and repair schedules– Some parts such as fluids, electrical systems and tracks have to be checked frequently for preventive measures. Keeping proper records allows you to have the tools and spare parts necessary on hand to avoid extended downtime.

Maintenance records are also important for your employees’ safety. Preventive maintenance schedules diminish the machine downtime significantly.

products details:

21 inch color screen control display

Using 21-inch color screen to control the display,

The single-arm suspension is easy to operate and saves floor space.

The operation is safe and reliable, the interface is simple and friendly,

With complete operation tips and troubleshooting guidelines.

Precision drilling box

Using independently developed CNC drilling box, Manufacturing in accordance with international standards,After three-coordinate detection, the accuracy is guaranteed.

Double clamping and feeding

The double-clamping mechanism is adopted, and the board feeding and positioning are automatically controlled according to the computer drilling program to improve the drilling accuracy.Effectively prevent the edge banding tape from being scratched.

Taiwan's Syntec servo motor

1.Servo control clamp

2.Fast and precise positioning

3.The clamp moving speed can reach up to 130m/min

Flexible discharge

Match with automatic lifting unloading table A variety of unloading options to facilitate automatic connection

Taiwan HIWIN Ball Screw Drive

Using ball screw drive, the screw drive error is within 0.05-0.1MM, the cumulative error is within ±0.2MM, and the service life of the whole machine is improved.

Automatic oil injection system

Cylinder-type oil injection system, all rails use independent cylinders to supply oil, ensuring that all rails are evenly oiled every time.