Views: 10 Author: Site Editor Publish Time: 2021-10-12 Origin: Site

As we all know, the Granite Block Cutting Machine is a very practical engraving equipment. Its precision machine performance is related to its components. Therefore, every part of the engraving machine is very important. However, the importance of the engraving machine components is also divided into primary and secondary. So, what are the very important parts of the cnc stone cutting machine? Below, let the stone engraving machine manufacturers introduce it.

1. The engraving head motor of the engraving machine is very important, because the engraving head motor is generally not covered by the warranty, and the engraving head motor is working continuously for a long time, so if the engraving head motor is not good, it will affect the use of the engraving machine. .

2, the speed of the engraving head motor can be adjusted, the general speed adjustable range is several thousand to 30,000 revolutions per minute. If the speed is not adjustable or the speed adjustable range is small, then the application range of the stone engraving machine is very The big limitation is that because different materials are engraved, different engraving head speeds must be used.

3. The drive controller is only the driver. All the calculation work is done by the computer. When the engraving machine is working, the computer is in a waiting state and cannot perform the typesetting work. The single-chip controller is controlled by a single-board machine or a single-chip computer. This controller is actually a computer, so as long as the engraving machine starts working, the computer can immediately perform other typesetting work, especially when engraving for a long time. obvious.

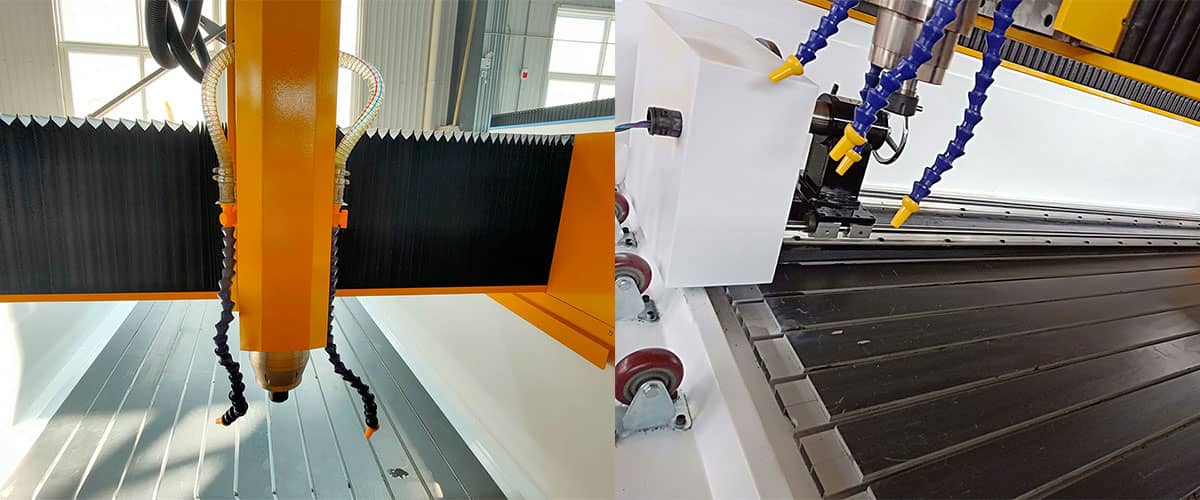

4, screw and guide rail are also an important part of the engraving machine, good screw and guide rail is the guarantee of precision and performance when the engraving machine is used for a long time.

The Granite Block Cutting Machine is applicable for cutting marble block into tiles and separated by horizontal blade, featured by precise cutting, high efficiency and easy operation.

As a cnc stone router supplier,Dekcel cnc equipment company will send the operation manual,necessary accessories,and installation instructions together with cnc stone engraving machine to clients factory.In this article,it illustrates a few points for the proper operation of cnc marble or granite router.

1.Please make sure the cnc router for stone machine and computer all connected well before starting the stone engraving machine,and then open the power supply of cnc stone carving machine and computer.If there is nothing wrong about industrial cnc stone router,then it's ready to go.

2.The second step is set the program by the stone router DSP control system or NC studio.After turning on the stone cnc machine control system,select the "back to machine origin" menu.Granite router for sale will automatically return to the origin and correct the coordinate system.In some cases,the marble stone router user does not need to perform mechanical reset operations,when restart the marble cnc machine for sale after a normal shutdown and still want to continue the previous operation.NC studio control system will save the current coordinate information when stop the working of granite cnc carving machine.

3.Before the whole cnc router for marble engraving processing, cnc stone table router users generally need to load processing procedures, otherwise,some functions related to the automatic processing will be invalid.Select"open (F)|open (O)..."The menu will pop up the windows standard file operation dialog box,where you can select the drive, path,and file name you want to open.Once the "open" button is clicked,the processing program of cnc granite router machine has been loaded with program.

4.Determine the origin of cnc stone carving machine.Make X axis,Y axis go at original position of the workpiece,set the current point as cnc machine for stone origin,or clear the current position in the coordinate window,in this way,the cnc stone machine for sale will regard current position as starting point to process.

Detail pictures: