Views: 47 Author: Site Editor Publish Time: 2022-03-16 Origin: Site

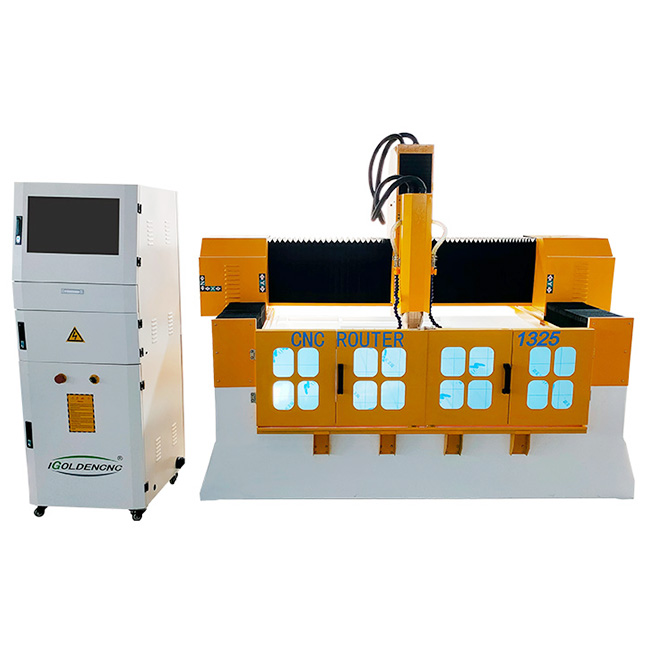

Stone Engraving Cnc Router / stone engraving machine is specially designed for engraving / carving / cutting stone or similar material. Optional water tank and automatic water cooling system make stone processing works easier and more convenient.

1) Heavy duty steel machine bed, it's very strong and stability;

2) Powerful 5.5kw water cooling spindle, perfect working for stone carving;

3) With DSP A11 control system, without connect with computer and easy to operation

Stone engraving machine for sale Features:

1, Square tube lathe bed, good rigidity and strength, it can load heavy materials.

2, Adopt Taiwan linear square guide rail. The bearing of the lead guide rail is face to face, smooth operation and high precision, long time.

3, Powerful spindle motor, cutting intensity, high efficiency. Water cooling for more than 24 hours continuous working.

4, High speed drivers, fast speed and great strength, with high performance subdivision ensure to work stably for long time.

5, Water proof and dustproof design for the granite engraving CNC machine protects the transmission parts from broken.

6, Break point and break knife continue engraving function, can engrave at any place as you like.

7, Strong compatibility: compatible various CAD/CAM software like Type3/ Artcam/ Castmate/ Pro-E/ Corelerow/ Wentai.

8, Automatic Lubricating system to make the maintenance easy and longer the cnc machine’s life.

9, With water tank and double water cooling system, high efficient works.

5 Tips to Maintain the stone engraving machine:

1. Maintain Cleanliness

Sweep and clean the table every time you operate the machine by washing the mud (dirty stone water) with clean water and blowing the dust away using an air gun. Messy surroundings lead to the buildup of dirt and debris, which enter the lubrication system and halt the machine’s operations.

Keep the lead screw clean to block foreign substances from lingering on it. The screw is utterly crucial, as it determines the machine’s accuracy and plays a significant role in the transmission process.

Do not overlook cleaning the industrial control box regularly since dust is the greatest killer of the circuit board and can cause a short circuit. Clean out the dust collected on the platform and the transmission system.

Filters must get cleaned regularly, and timely replacements must be done. Dirty filters can cause poor heat dissipation and malfunction.

2. Maintain Ideal Surroundings and a Controlled Environment

Estimate the applicable temperature of the fueling standard to at least the minimum temperature. If you are not yet using the CNC machine, which is kept in an environment with exceedingly low room temperatures, it is advisable to pour out the water stored in the tank so that the tank and water pipe do not crack.

Several operators add butter to the screw and skip cleaning up during winters, which puts pressure on the machine upon starting up. Some workrooms have significantly low temperatures, due to which the added oil can still get frozen.

Maintain minimal humidity levels in the operation room to prevent rapid wear and tear, poor electrical contact, and short circuits of electrical accessories of the CNC machine.

It is also crucial to note the electromagnetic interference in the operation room. If the interference value is enormous, the machining accuracy plummets. CNC machines must also be kept away from the apparatus that creates high vibration to block interference.

3. Frequent Lubrication

CNC machines require frequent lubrication to ensure seamless functionality and avert premature wear. Each component of a CNC machine, including the lead screws, the spindles, the guide rails, tool holder, bearings, and sliders, demands timely and appropriate lubrication to dampen the wear speed.

You must stick to the manufacturer’s recommendations and go for grease or oil. Improper lubrication can make the machine parts stick together or restrict their movements, causing further problems.

Begin by cleaning the guide rails and lead screws and then using a rag to wipe off the oil and material debris collected on them. During low temperatures, consider adding oil to the lead screws and rails.

If you have not used the machine for prolonged periods, it is advisable to have it refueled regularly to maintain the transmission system’s flexibility. Upon adding the oil successfully, move the component back and forth slowly to ensure that you evenly spread the lubricating oil to the lead screw and the guide rail.

4. Regular Inspection

Ensure the reliability of the moving components of the CNC machine each month, especially the drivers, motors, and fixing screws. When conducting daily inspection checks of the CNC machine, have the power disconnected, hold on until the monitor goes blank and the main circuit power indicator has been cut off.

Damaged CNC tools and parts can negatively impact cut accuracy and quality. Therefore, you must inspect the working condition of CNC cutting tools, collets, tool holder, tool holder forks, CNC suction cups, table gaskets, jigs and ensure timely replacements.

5. Cooling Water for Spindle Motor

Cooling water is undoubtedly critical for the water-cooled spindle motor. Dirty cooling water can cause significant damage to the motor. You must never dehydrate the water spindle motor and ensure regular replacements of the cooling water to prevent surging water temperatures.

During winters, if the working environment temperature drops substantially, the water in the tank can get substituted with antifreeze. Closely monitor the water level and never dehydrate the water-cooled spindle motor. Otherwise, the motor heat will fail to export in time.

Yet another parameter to monitor closely is the ambient temperature. You must be careful since the water temperature is exceedingly low and can freeze the water tank and water pipe. Instead, you can use antifreeze for cooling.

Marble Granite Stone Engraving CNC Router Machine parameters:

| Working area | 1300*2500*500mm |

| Spindle | HQD 3/4.5/5.5/7.5KW water cooling spindle |

| Inverter | Fuling |

| Motor | Stepper motors |

| Driver | Stepper driver 860H |

| Control System | Nc studio control system |

| Table | Aluminum table with water tank |

| Oil lubrication | With |

| Limit | Omron limit |

| Transmission | XY axis helical rack Z axis Taiwan ball screw |

| Rail | X, Y, Z axis Taiwan HIWIN Square guide rail |

| Screw | Z axis TBI ball screw |

| Bed | Thick steel welded structure |

| Voltage | 3 phase/380V |

| *Some specifications can be customized upon request, please contact us. | |

Applicable materials for The 1325 Marble Carving CNC Router :

1. Marble: Among personalized carvings, marble is the most ideal raw material of choice. The texture of marble is good and the color is solemn. Whether it is dark black, jet black, dark green, rose or gray, it gives people a very elegant beauty. . Therefore, on the basis of having many traditional products, it has recently developed to use laser technology to engrave photos, images and texts, which is quite popular.

2. Granite: The texture is very hard, wear-resistant and durable, and is widely used in prizes, souvenirs and construction. Granite belongs to the limestone system. Its obvious characteristic is that it has spots, the color and luster give people the appearance of “salt and pepper”, and some also have the texture of marble. Granite can accept various polishing and finishing treatments. In view of the many colors of granite, especially black and white granite is often used to engrave text, images, etc., the carved products have a strong visual effect and are very eye-catching.

3. Artificial marble: Artificial marble is made of natural marble or granite crushed stone as filler, cement, gypsum and unsaturated polyester resin as adhesive, and it is made after stirring, forming, grinding and polishing. Artificial stone has the following characteristics: light weight, high strength, corrosion resistance, pollution