Views: 16 Author: Site Editor Publish Time: 2021-09-26 Origin: Site

CNC wood router perfect functions, vertical emptying, grooving, and material cutting are completed in one step, completely replacing the traditional sliding table saw and electronic cutting saw, getting rid of the traditional opening method relying on manual labor, and using CNC drilling when opening the material At the same time that the group is installed vertically, it can truly realize intelligent production through integration with special design software.CN¥18,649.61-CN¥19,935.79

1.High temperature tempering treatment, welded steel tubeT type machine bed and T type gantry, high rigidity, bearing strength better.

2.Dual motor driver for Y-axis, moving stably.

3.Linear round guide rail, ensuring the higher precision and long life time.

4.WHD/HQD water cooling spindle, more powerful, low noise, not easy to break cutters.

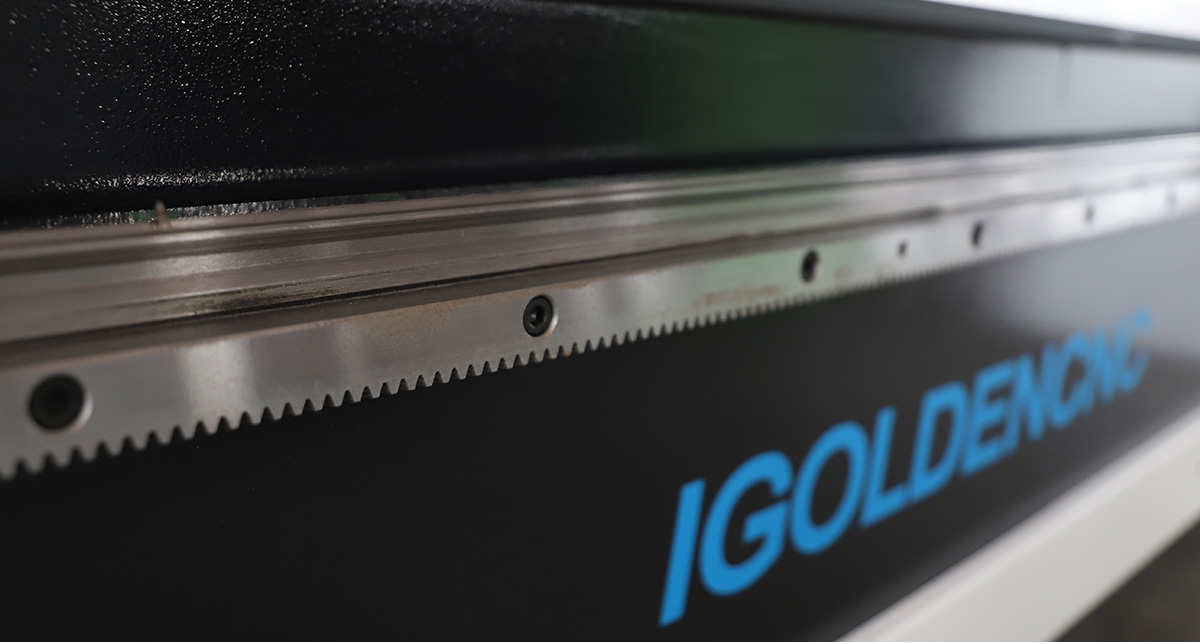

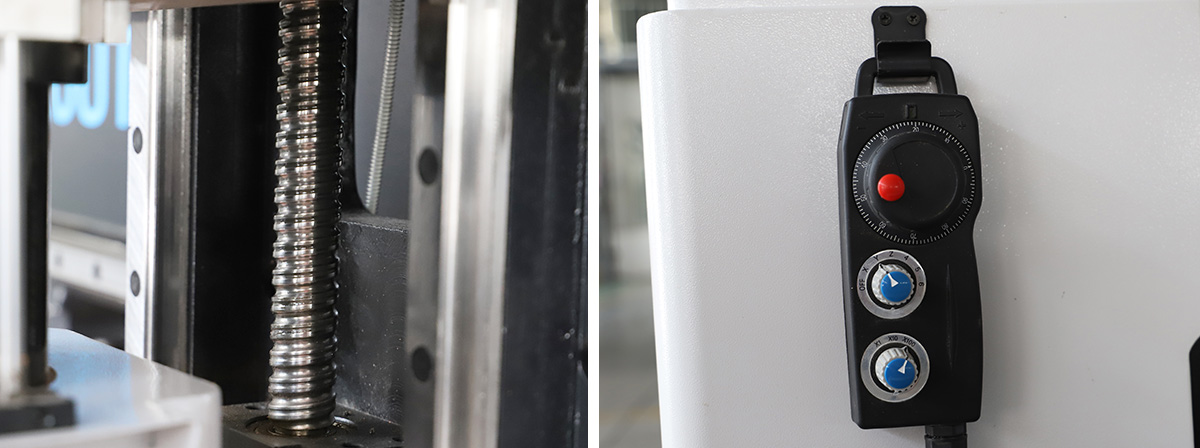

5.Square guide rail transmission for X Y-axis, ball screw transmission for Z-axis, ensuring the machine fast speed and higher precision.

6.Intelligent protecting the working table, to prevent the damage by wrong operation. Also can prevent the crush caused by the design working area larger than actual working area.

7. Emergency stop button, ensuring the operation safe.

8.Good software compatibility, suitable for Type3, Artcam, Castmate, Ucanam, JDpaint, such CAD/CAM design software.

9.Break points,power off memory way,ensuring the memory function,can continue processing if cutters break or next day working.

What the advantage of our cnc wood router?

Spindle Italy HSD Air Cooling Spindle

Top brand of the world. Spindle speed: 0-24000RPM.

Inverter

Taiwan Delta Inverter

It can output 150% of rated torque at zero speed, and it can have “point to point” and relative distance control functions for position control.

Motor

German SIEMENS servo motor

high working efficiency and stable running promised

Control system

SIEMENS 808D Controller

Thanks to its panel based design philosophy, and IP65’s protection level, the SINUMERIK 808 series is ideal for harsh environments.

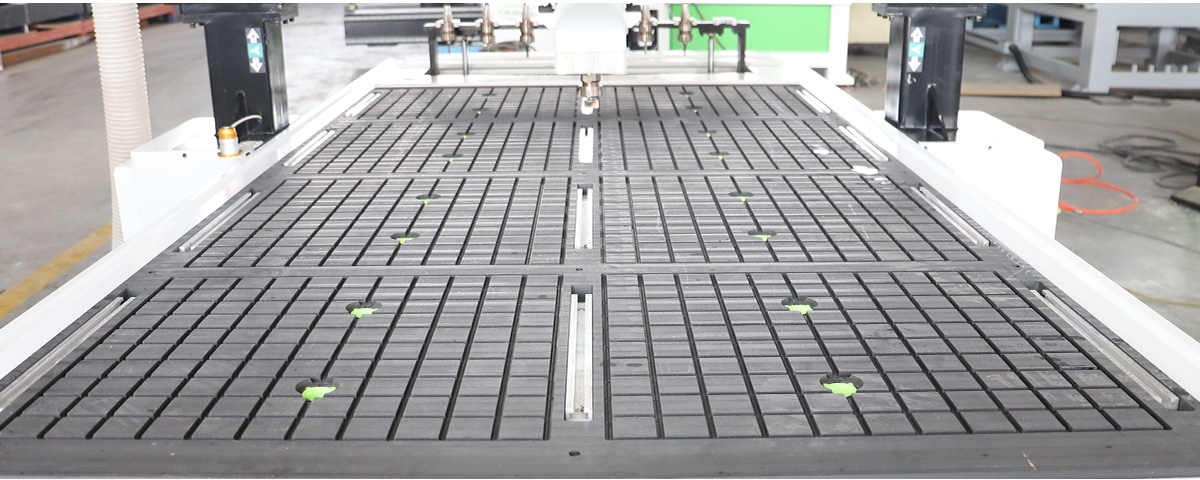

Working table

T-slot and Vacuum Table

Rigid vacuum table with grids and T-slots maximizes the vacuum hold-down and also enables you to clamp the workpiece in place.

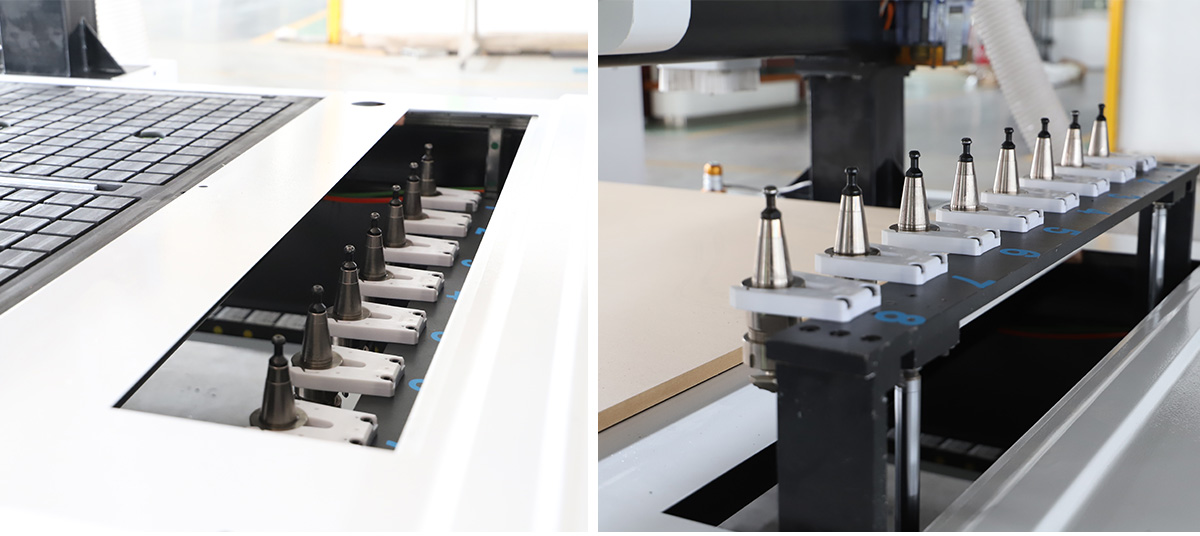

Tool magazine

Linear 10 PCS Tool Magazine

The use of an 10 Tool Rotary speeds up tool changes assuring faster times increasing production throughput.

HQD 9KW air-cooled tool change spindle

Vacuum and T slot table with 5.5kw cooling pump

Automatic tool change with liftable tool magazine

X,Y,Z axis Taiwan HIWIN Square guide rail

LNC Control System | Fuling Inverter

Taiwan ball screw | Control handwheel

cnc wood router application

CNC Wood carving machine is widely used in different industries.

a. Advertising industry: advertising signs and logos, molding, decoration products. It can cut and engrave wood, MDF, bamboo, plastic, PVC, acrylic, metals, stone, etc.

b. Furniture making: cnc wood carving is widely used in cabinet doors, solid wood doors, wooden doors, paint free doors, craft fan windows, tables and desks. Widely used in wood door artwork engraving, wave boards making, cylinder materials engraving, 3d photo engraving and etc.

c. Artwork industry: Figure engraving, character engraving and cutting, name brand making, small gift cutting, souvenirs making, carving decoration letters, figures on windows, fences, wall, etc.

d. Mold industry: wood carving machine can engrave metal molds, such as copper, aluminum, iron, also nonmetal molds such as marble, stone, plastic board, PVC pipe and wood board.

e. Other industries: cnc wood carving can engrave all kinds of large reliefs and shadow, which are widely used in the craft gift industry.