Views: 22 Author: Site Editor Publish Time: 2021-09-18 Origin: Site

Stone CNC Machine is also named granite cutter.It is a machine designed for granite cutting. As we know,granite material is harder than marble material and other stone material. So a granite cutting machine should be more stronger in order to cut granite materials. In this case,we need a stable and strong cutting motor, cutting blades and other parts. Actually, this machine can be used as Stone CNC Machine also. Use this granite cutting machine to make precision cuts in marble, granite,quartz materials up to 10cm thick. This 3d cnc stone machine features an adjustable cutting depth and is ideal for cutting both marble and granite.

The crossbeam move forward or backward by asynchronous motor, it is controlled by frequency converter. The spindle is driven by main motor with belt transmission and then have the blade rotated. The blade component move left or right by asynchronous motor with frequency converter for adjusting feed speed. Worktable can rotate 360° and locate every 45 degree by hydraulic system transmission.

Features of 3d cnc stone machine

Heavy duty steel wall structure, keep machine with very good stability.

Adopt good quality machine parts,to make machine with high performance and durability.

Spindle rotate 0-180 degree,can make engraving on different angles,like arc-surface milling,bending surface machining for 4D jobs.

With disk type automatic tool changer,spindle change tools automatically,no need manual work.

High Z design,suitable for large three dimensional product machining.

Advanced Syntec control system,very stable and easy to operate.

Dust proof,water proof.

3d cnc stone machine Applicable industry & material

Applicable industry: sintered stone application industry, fabricated building materials industry, home decoration materials industry, cutting marble, artificial stone, quartz stone and other materials.

Applicable material: sintered stone, ceramic plate, quartz stone, marble, etc.

Detailed of 3d cnc stone machine

MACH 3 Controller

Mach3 is designed to control the CNC machine. The program is installed on a computer connected to the control machine. Mach3 was

developed by American programmers, both for professional and amateur use, so it is the most common software for CNC machines in the world. Using Mach3, it is possible to control the following types of machines: turning, milling, routers, laser and plasma plotter, engraving.

Stone CNC Machine Technical Data

| Workpiece Size | mm | 350*1000*6 |

| Z Axis Working Height | mm | 600 |

| Positioning Accuracy | mm | 0.05 |

| Re-positioning Accuracy | mm | 0.02 |

| Body Structure | Welding Body | |

| X, Y, Z Axis Structure | Linear Guide Rail, Ball Screw | |

| Max. Running Speed | mm/min | 30000 |

| Max. Working Speed | mm/min | 15000 |

| Spindle | kw | 5.5kw Water-cooling Spindle*6(6-12 Spindle Optioned) |

| Spindle RPM | rpm/min | 24000 |

| Working Voltage | V/Hz | AC 380V±10%/50-60Hz |

| Machine Weight | kg | 6300kg |

Stone CNC Machine Configuration

| Spindle | HQD Water-cooling Spindle (Italy HSD Spindle Optioned) | Machine Body | Heavy-duty Split-type Welding Body, Fixed with Screw |

| Worktable | Complex Worktable ( Rotary Device Optioned) | Control System | DSP Control System(Taiwan SYNTEC System Optioned) |

| Servo Motor | Japan YASKAWA(Leadshine or Yako Optioned) | FrequencyConverter | Taiwan DELTA |

| Gear Rack | Taiwan HIWIN | Reducer | Japan SHIMPO |

| Electric Components | France SCHNEIDER | Limited Switch | Japan OMRON |

| Tool Setting | High-precision Automatic Tool Setting Device (Optioned) | Lubrication System | Automatic Lubrication Device (Optioned) |

| Optioned | Automatic Leveling Device | ||

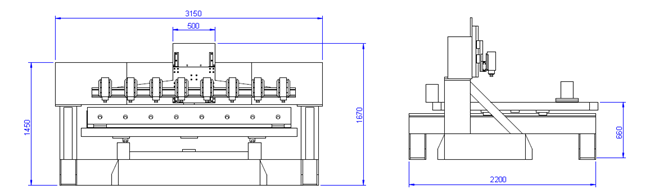

Stone CNC Machine Size