Views: 9 Author: Site Editor Publish Time: 2021-09-09 Origin: Site

How to choose a suitable Acrylic CNC machine? Choosing a suitable acrylic cutting machine is very important for the users. Before purchasing the machine, they’d better consider the following aspects:

Acrylic processing requirements

When choosing the Acrylic CNC machine, the users should consider the size, thickness, and processing requirements at first.

1、 ·Thin acrylic board cutting and marking:

When cutting acrylic boards, if it is a thin sheet, less than 20 mm, the users choose an acrylic laser cutting machine. If you need to engrave letters, LOGO, and other graphics on the surface of acrylic or PMMA, it’s better to choose a laser cutting machine.

2、·Thick acrylic board cutting and embossing

If the thickness of acrylic boards exceeds 20 mm, it is recommended to choose a CNC cutting machine for acrylic processing. When the users need to groove and emboss their designs on the acrylic materials, a CNC cutting machine is the optimal.

They can also consult with the suppliers of laser engraving or CNC Router machine to obtain professional opinions and suggestions.

3、Sizes of the acrylic materials

The users may also consider the size of the materials for laser processing. It is about the choice of the size of the working table of the laser engraving machine. But the users should notice that the large size of the machine is not necessarily good. Because the large-size equipment is of course more expensive.

4、Factory visit

We recommend that users visit the manufacturer’s factory of the laser engraving machine before procurement. The buyers visit the manufacturing factory, communicate with the manufacturer as much as possible. In this way, they can get an in-depth understanding of the manufacturer’s strength and test the operation performance. They can also see the actual processing effect and discuss the after-sales service. After knowing the acrylic cutting machine well, they can make the best choice.

Machine Features of Acrylic CNC machine

1. Whole cast iron machine structure, tight and strong, can ensure machine runs smoothly.

2. Best choice for wood, advertising materials, with dust proof on all three-axis, it can stop dust away from the rails and ball screw and to keep the machine working for longer time.

3. Imported high precision HIWIN rails linear bearings, smooth movement to ensure the machine tools high precision.

4.Low noise, water cooling system, high rotated speed 24000RPM, can realize only diameter 1mm tools engraving on the hardness materials.

5. Processing metal materials can add water cooling system, which can cool the tools, avoiding the high temperature breaking tools.

6. Good software compatibility can compatible with Artcam/Type3/ Ucancam/JDPaint such as CAD/CAM, 2D/3D processing more convenient to use

Now, when you’ve chosen the acrylic, bit, and design, begin with Acrylic CNC machine.

Step 1:- First things first, you’ve to set the feed rate according to the bit size. The most recommended range is between 75-300 IPM. High feed rates work best with large-sized bits. Smaller bits need a lower feed rate.

Step 2:- In this step, you’ve to set the RPM. The recommended value is 18,000 RPM for optimizing the spindle’s ability to cut through the acrylics, without melting the acrylics.

Step 3:- In the third step, you’ve to set the cutting depth. Experts suggest that cutting depth must be 1/2 of the diameter of the bit. It prevents the bits from breaking.

Step 4:- In the fourth step, you’ve to begin cutting with a ramp. You can select the option within the software. Opting for ramping rather than plunging is to deter distortion

Step 5:- Now, you’ve to secure the acrylic material on the CNC router table.

Step 6:- Finally, run the CNC router for cutting acrylic in a design you want

Parameter Configuration

Model | IG-1325 |

Bed structure | G1 bed, G1 column |

principal axis | New 5.5kW water cooled spindle |

Drive | leadshine 850W servo |

Reducer | SHIMPO |

System | NCStudio 95A |

Cabinet | Independent computer cabinet |

Guide | Taiwan HIWIN 25 guide rail |

Feed height | 200mm |

Mesa | Vacuum adsorption absorbable and clamping table |

Rack | new moon |

Vacuum pump | 7.5kW water cooling vacuum pump |

Vacuum cleaner | 3KW double tube dust collector, three axis dust-proof |

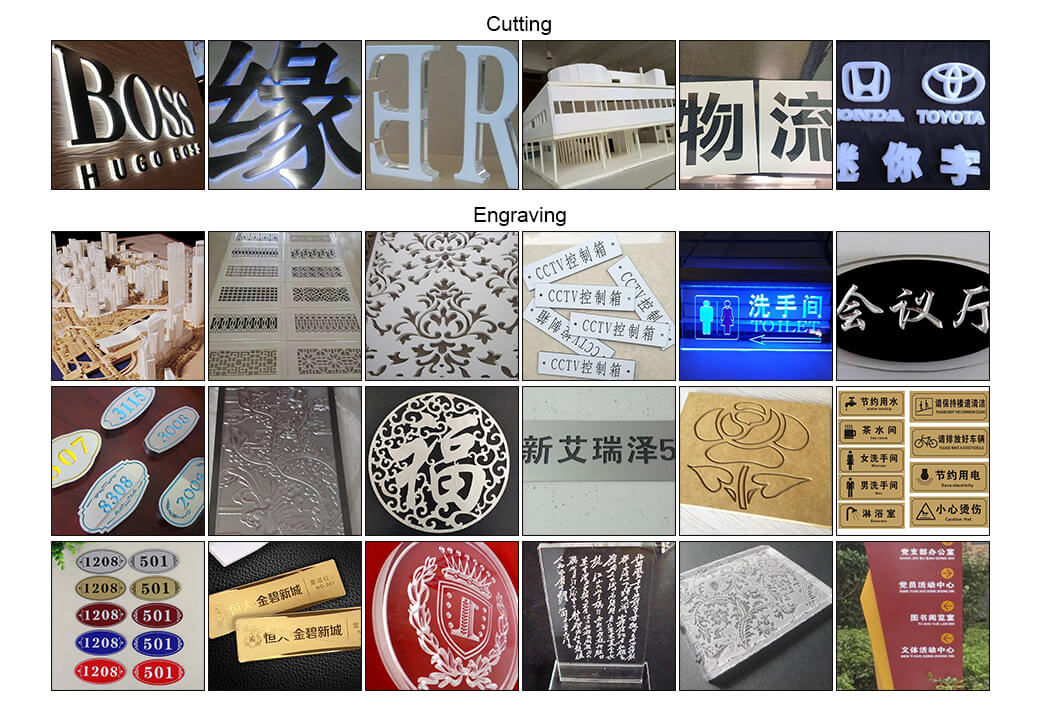

Acrylic CNC machine Application:

Advertising industry: acrylic cutting, MDF engraving cutting and engraving, wood decoration products making. Recommend model CX1325 cnc wood router.

wood door: MDF and wood door engraving, recommend model: CXM25 cnc router 1325.

wood furniture: cabinet door making with complicated design, recommend model:

Multi- heads pneumatic ATC router cnc, Linear auto tool changing cnc router, Carousel wood cnc router with 12 disc tools

Panel furniture: wood panel cabinet making, recommend model: automatic loading unloading penal processing cnc router with drilling/boring bits.

Scope of Application