Views: 31 Author: Site Editor Publish Time: 2021-08-12 Origin: Site

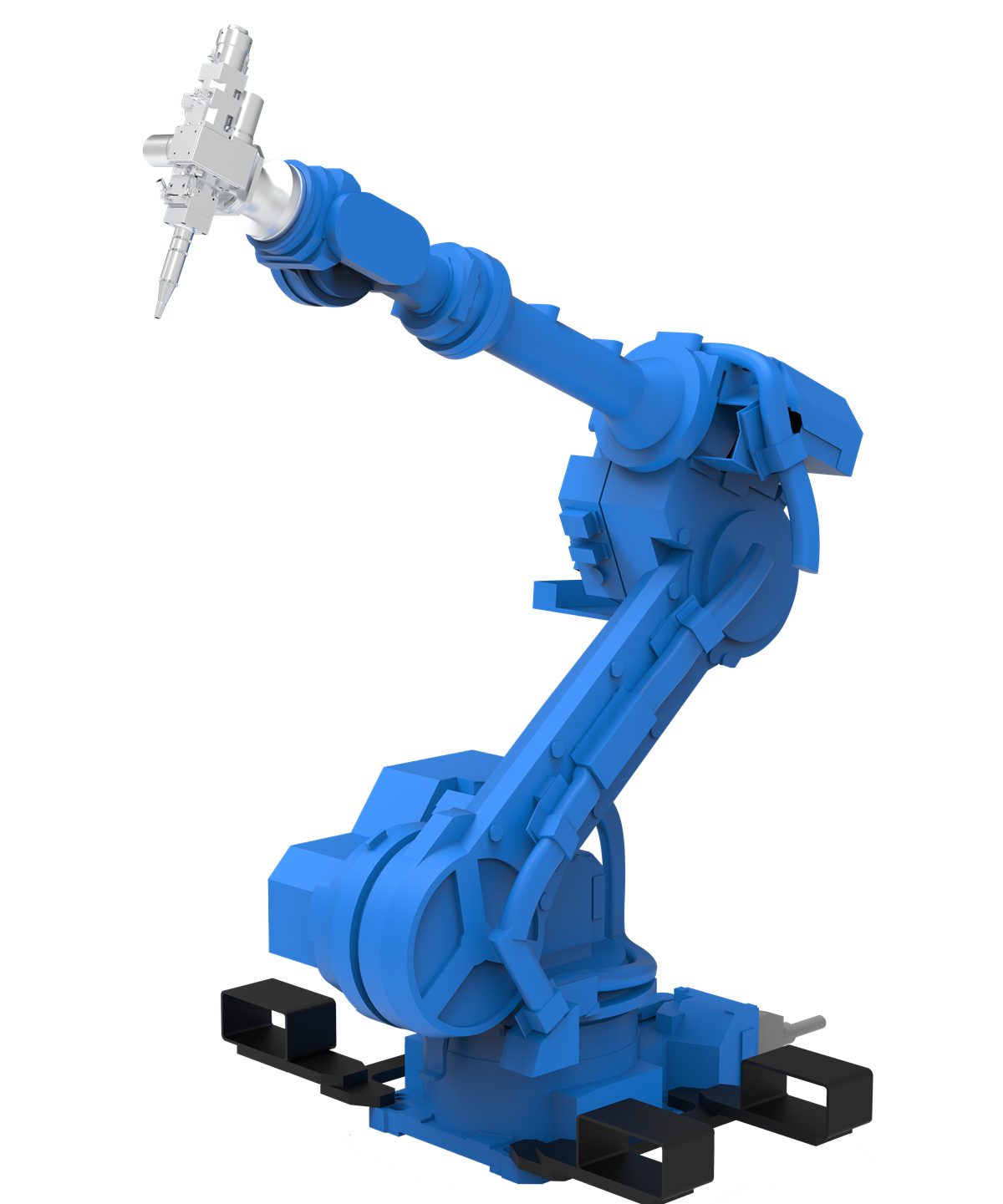

A robot laser welding system consists of a servo-controlled, multi-axis mechanical arm, with a laser cutting head mounted to the face plate of the robot arm.

The cutting head has focusing optics for the laser light and an integral height control mechanism. An assist gas delivery package distributes a gas, such as oxygen or nitrogen, to the welding head. Most systems use a laser generator that delivers the laser light to the robot cutting head through a fiber-optic cable.

A Robot Laser Welding Machine can easily automate this application and manufacturers will see improved repeatability and higher quality welds.

The welding robots iGWL-RW- 1500 arc HW are optimized for continuous-path applications such as arc welding and the application of adhesives and sealants. The industrial robots offer ideal performance combined with a high power density - for maximum economy at low cost.

Cost-effective, flexible robots for applications such as arc welding, adhesive bonding application or laser cutting

With their new controller structures, the industrial robots iGWL-RW- 1500 arc HW have extremely high path accuracy and speed. The acceleration values and the new ergonomic design with minimized disruptive contours ensure continuous-path motion at the very highest level - even deep inside the workpieces.

Extremely fast, uncompromisingly precise continuous-path motion: the hollow-shaft robot impresses with maximum performance at minimum cost.

Any installation position

The robot can be floor-, wall- or ceiling-mounted or even installed at a certain angle - exactly in line with your requirements.

Software add-ons

With digital Motion Modes, you can simply adapt the performance of the robot via the robot controller - e.g. for optimized precision or speed

Reduction of your TCO

The long service life and maintenance-free axes 4-6 sustainably reduce your TCO.

Suitable for compact cells

With a compact design and small footprint, the robots ensure optimal utilization of the space in robotic cells.

Machine Parameters

Model | iGWL-RW- 1500 | iGWL-RW- 2000 | iGWL-RW- 3000 | |

Laser power | 1500W | 2000W | 3000W | |

Laser wavelength | 1080±10nm | |||

Robot | FANUC--Six-axis welding robot | |||

Maximum load on wrist | 12KG | |||

Repositioning accuracy | ±0.03mm | |||

Range of motion |

Lower arm | J1 | 340º/370º | |

J2 | 235º | |||

J3 | 455º | |||

Upper arm | J4 | 380º | ||

J5 | 380º | |||

J6 | 900º | |||

Max speed |

Lower arm | J1 | 260º/s | |

J2 | 240º/s | |||

J3 | 260º/s | |||

Upper arm | J4 | 430º/s | ||

J5 | 450º/s | |||

J6 | 720º/s | |||

Thickness of welding material | ≤4mm | ≤6mm | ≤8mm | |

Welding gap requirements | ≤0.3mm | |||

Voltage | 380V±10% | |||

Total power | ≤8kw | ≤10kw | ≤12kw | |

Gross weight | 200KG | |||

Remarks: Can be customized according to customer requirements | ||||

Comparison of Laser Welding and Traditional Welding

Welding method | Heat affected zone | Thermal deformation | Weld quality | Whether to add solder | Welding environment |

Laser welding | Smaller | Smaller | Better | No | No special requirements (except for special industries) |

Brazing | General | General | General | Yes | Overall heating |

Argon arc welding | Larger | Larger | General | Yes | Need electrodes |

Resistance welding | Larger | Larger | General | No | Need electrodes |

Plasma arc welding | General | General | General | Yes | Need electrodes |

Electron beam welding | Smaller | Smaller | Better | No | Vacuum |

Laser Welding Speed

Collimating focal length:150mm Focus length:250mm Fiber diameter:50μm Protection gas>15L/min | ||||

No. | Material | Output Power | Penetration(mm) | Speed(m/min) |

1 |

Stainless steel | 500 | 1.5 | 0.85 |

2 | 500 | 1 | 2.55 | |

3 | 500 | 0.5 | 6.8 | |

4 | 750 | 2.5 | 0.85 | |

5 | 750 | 2 | 2.55 | |

6 | 750 | 1.5 | 2.17 | |

7 | 750 | 1 | 6.8 | |

8 | 1000 | 0.5 | 8.5 | |

9 | 1000 | 3 | 0.85 | |

10 | 1000 | 2.5 | 2.55 | |

11 | 1000 | 2 | 3.4 | |

12 | 1000 | 1.5 | 5.1 | |

13 | 1000 | 0.5 | 12.75 | |

14 |

Carbon steel (low) | 500 | 1 | 1.28 |

15 | 500 | 0.5 | 5.1 | |

16 | 750 | 2 | 0.85 | |

17 | 750 | 1.5 | 2.55 | |

18 | 750 | 1 | 5.95 | |

19 | 750 | 0.5 | 7.62 | |

20 | 1000 | 2.5 | 0.85 | |

21 | 1000 | 2 | 2.55 | |

22 | 1000 | 1.5 | 4.25 | |

23 | 1000 | 1 | 6.8 | |

24 | 1000 | 0.5 | 11.05 | |

25 |

Aluminium | 500 | 1 | 0.85 |

26 | 750 | 1 | 1.7 | |

27 | 1000 | 1 | 3.4 | |

28 | 1000 | 2 | 0.85 | |

29 | Copper | 1000 | 0.3 | 1.7 |

The benefits of Robot Laser Welding Machine:

As mentioned, robotic laser welding is inherently precise. Laser welding beams create deep and accurate welds without using nearly as much energy or resources as traditional welding processes. Since laser welds are so precise and focused, welds are cleaner and require far less touch-up or rework.

Laser welding solutions are also more versatile. Traditional welding methods will always excel at applications where there is a gap between welding parts, but other applications that would benefit from high accuracy and speed will be better off with laser welding. Robotic laser welding has a much smaller heat-affected zone, so distortion is minimized regardless of the type of metal being welding.

Robotic laser welding is an accurate, clean and flexible option for a wide variety of welding applications. While it will never be a replacement for traditional welding processes, it still has many benefits and any manufacturer looking to automate welding processes should at least consider a robotic laser welding solution.

Robot controller systems

1)Structural optimization algorithm suitable for the body control of various types of structure.

2)Modular setting of functionssuitable for diverse applications. 8-axis control realizes the control of external axes (traveling axes and positioner).

3)Suitable for multiple increments; absolute servo.

Open structure for synchronization of international technology and extension of functions.

4)Software PLC functions facilitate logic control.

Process functions make programming easy.

5)Improved computer bus connection ensures reliability and practicability.

6)Safety module ensures safe production of the robots.

Industrial standards &reliable stability.