iGWL-AW Series The robot laser welding machine is composed of a dedicated fiber laser head, a high-precision capacitance tracking system, a fiber laser and an industrial robot system. It is an advanced equipment for flexible welding of metal sheets of different thicknesses from multiple angles and multiple directions.

iGWL-AW

iGOLDENLASER

| Availability: | |

|---|---|

Video

Robotic Welding Machine Description:

It is widely used in metal processing, machinery manufacturing and auto parts manufacturing that have processing requirements for three-dimensional workpieces.

3D Industrial Laser Welding Robot iGWL-AW Series

The robot laser welding machine is composed of a dedicated fiber laser head, a high-precision capacitance tracking system, a fiber laser and an industrial robot system. It is an advanced equipment for flexible welding of metal sheets of different thicknesses from multiple angles and multiple directions.

It is widely used in metal processing, machinery manufacturing and auto parts manufacturing that have processing requirements for three-dimensional workpieces.

3D Fiber Laser Beam Welding Robot Parameters:

Model | iGWL-RW- 1500 | iGWL-RW- 2000 | iGWL-RW- 3000 | |

Laser power | 1500W | 2000W | 3000W | |

Laser wavelength | 1080±10nm | |||

Robot | FANUC--Six-axis welding robot | |||

Maximum load on wrist | 12KG | |||

Repositioning accuracy | ±0.03mm | |||

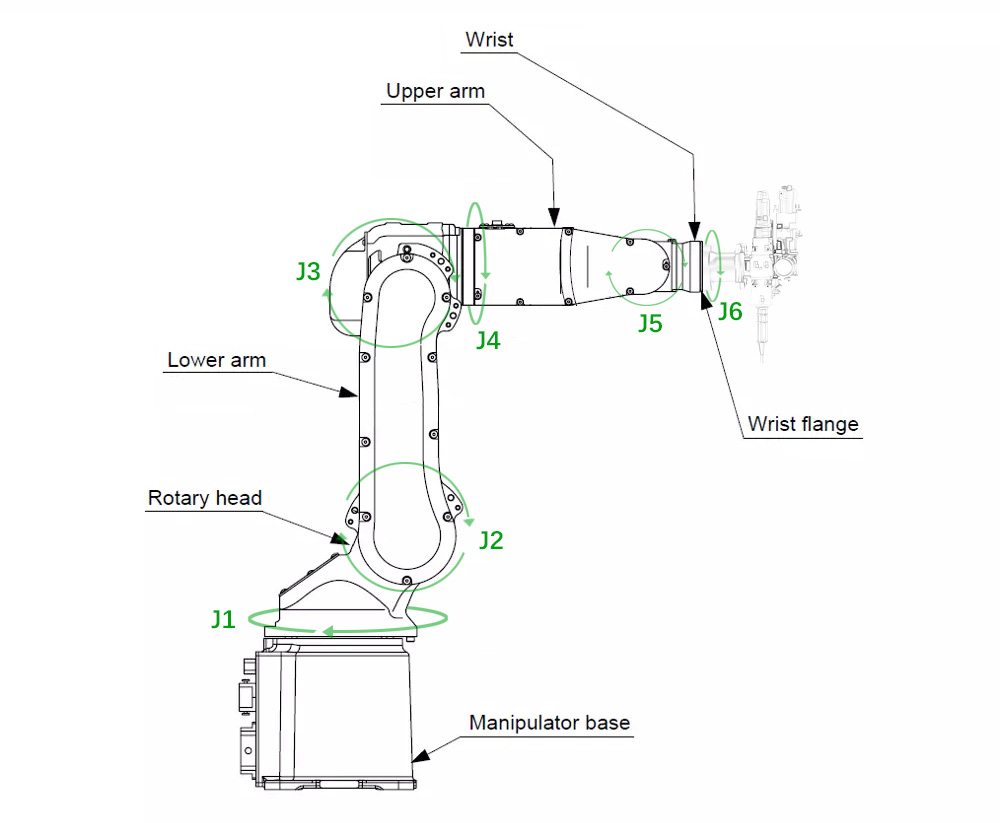

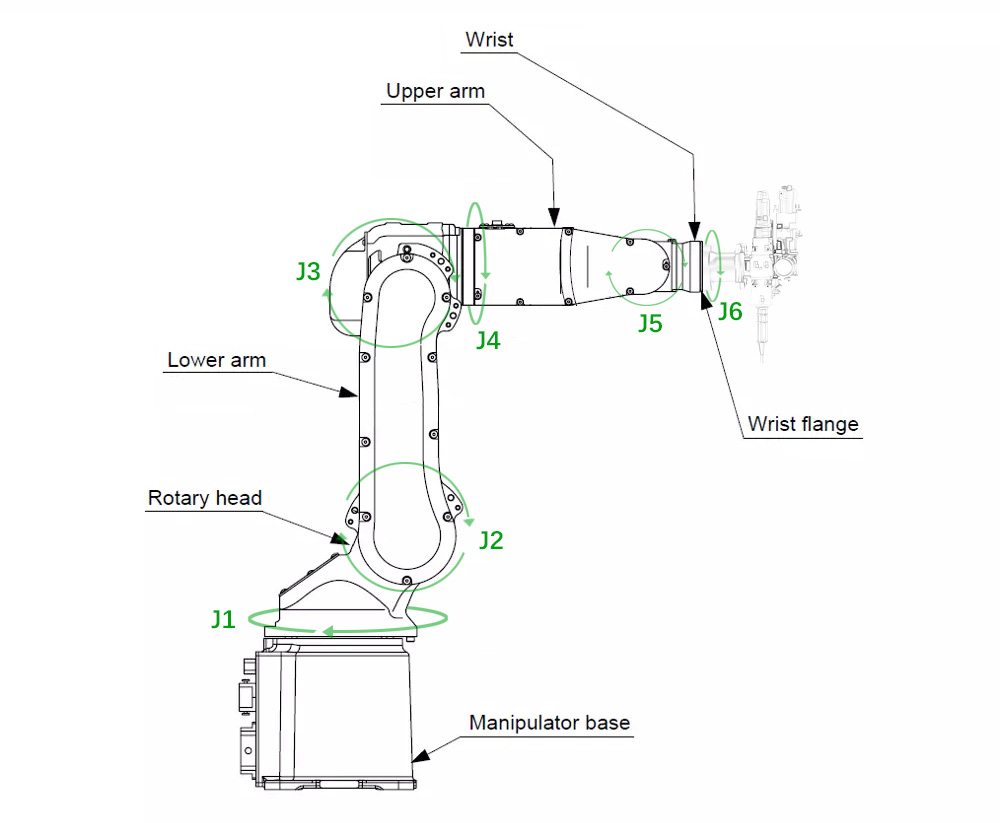

Range of motion |

Lower arm | J1 | 340º/370º | |

J2 | 235º | |||

J3 | 455º | |||

Upper arm | J4 | 380º | ||

J5 | 380º | |||

J6 | 900º | |||

Max speed |

Lower arm | J1 | 260º/s | |

J2 | 240º/s | |||

J3 | 260º/s | |||

Upper arm | J4 | 430º/s | ||

J5 | 450º/s | |||

J6 | 720º/s | |||

Thickness of welding material | ≤4mm | ≤6mm | ≤8mm | |

Welding gap requirements | ≤0.3mm | |||

Voltage | 380V±10% | |||

Total power | ≤8kw | ≤10kw | ≤12kw | |

Gross weight | 200KG | |||

Remarks: Can be customized according to customer requirements | ||||

Comparison of Laser Welding and Traditional Welding

Welding method | Heat affected zone | Thermal deformation | Weld quality | Whether to add solder | Welding environment |

Laser welding | Smaller | Smaller | Better | No | No special requirements (except for special industries) |

Brazing | General | General | General | Yes | Overall heating |

Argon arc welding | Larger | Larger | General | Yes | Need electrodes |

Resistance welding | Larger | Larger | General | No | Need electrodes |

Plasma arc welding | General | General | General | Yes | Need electrodes |

Electron beam welding | Smaller | Smaller | Better | No | Vacuum |

Laser Welding Speed

Collimating focal length:150mm Focus length:250mm Fiber diameter:50μm Protection gas>15L/min | ||||

No. | Material | Output Power | Penetration(mm) | Speed(m/min) |

1 |

Stainless steel | 500 | 1.5 | 0.85 |

2 | 500 | 1 | 2.55 | |

3 | 500 | 0.5 | 6.8 | |

4 | 750 | 2.5 | 0.85 | |

5 | 750 | 2 | 2.55 | |

6 | 750 | 1.5 | 2.17 | |

7 | 750 | 1 | 6.8 | |

8 | 1000 | 0.5 | 8.5 | |

9 | 1000 | 3 | 0.85 | |

10 | 1000 | 2.5 | 2.55 | |

11 | 1000 | 2 | 3.4 | |

12 | 1000 | 1.5 | 5.1 | |

13 | 1000 | 0.5 | 12.75 | |

14 |

Carbon steel (low) | 500 | 1 | 1.28 |

15 | 500 | 0.5 | 5.1 | |

16 | 750 | 2 | 0.85 | |

17 | 750 | 1.5 | 2.55 | |

18 | 750 | 1 | 5.95 | |

19 | 750 | 0.5 | 7.62 | |

20 | 1000 | 2.5 | 0.85 | |

21 | 1000 | 2 | 2.55 | |

22 | 1000 | 1.5 | 4.25 | |

23 | 1000 | 1 | 6.8 | |

24 | 1000 | 0.5 | 11.05 | |

25 |

Aluminium | 500 | 1 | 0.85 |

26 | 750 | 1 | 1.7 | |

27 | 1000 | 1 | 3.4 | |

28 | 1000 | 2 | 0.85 | |

29 | Copper | 1000 | 0.3 | 1.7 |

Details Of The Robot Laser Welding Machine:

| JPT Laser We use advanced fiber lasers with a service life of more than 10w hours, low energy consumption, low failure rate, flexible fiber up to 10-15m, flexible and convenient, outdoor welding, equipped with a hard protective layer. |

| WSX Professional welding head 1. This welding head has strong advantages in aluminum alloy welding and medium power welding applications, and it is a cost-effective welding head. 2. The welding head uses a motor to drive the X, Y axis vibrating lens, with a variety of swing modes, and the swing welding allows the workpiece to have irregular welds, larger gaps and other processing parameters, which can significantly improve the welding quality. 3. The internal structure of the welding head is completely sealed, which can prevent the optical part from being polluted by dust. 4. The protective lens adopts a drawer type structure, which is easy to replace. 5. It can be equipped with various lasers with QBH connectors. |

|

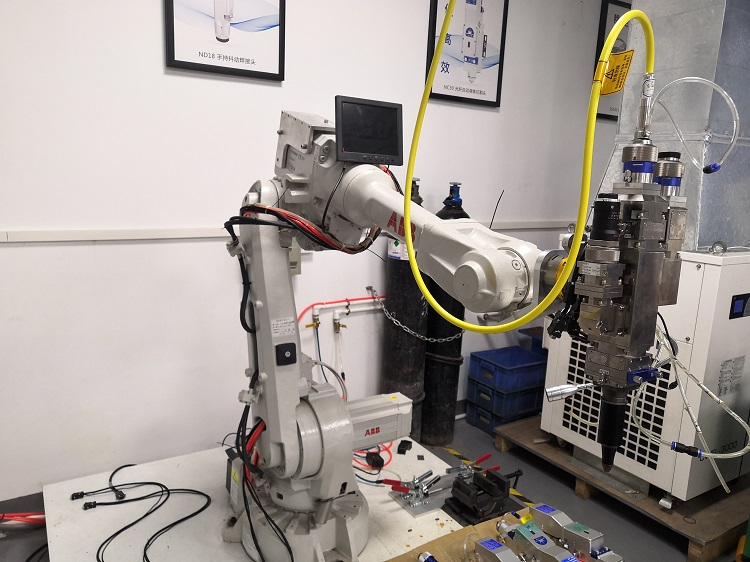

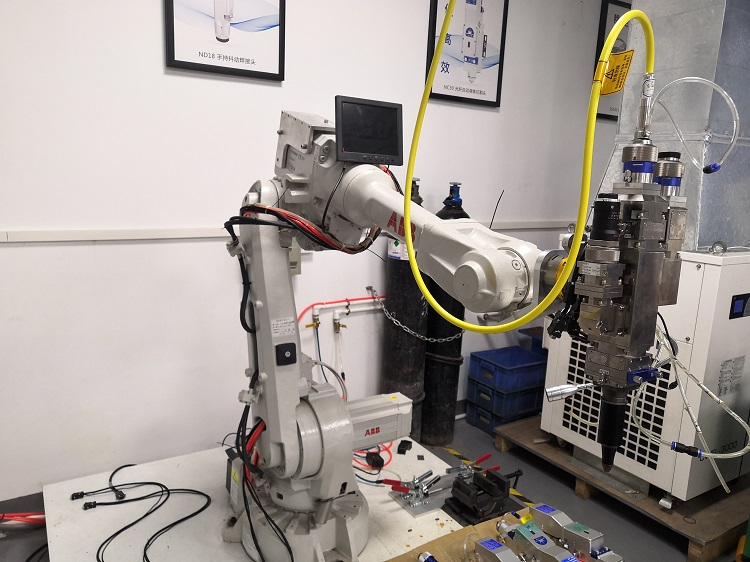

Robot Six-axis LinkageThe six-axis linkage of the robot can easily realize the welding of three-dimensional workpieces. With special tooling and linkage workbench, it can realize fully automatic welding with one clamping. |

| Multi-axis mobile welding table The whole machine is designed with a thick aluminum plate, and the structure is firm High positioning accuracy and sensitive response No need to manually move the product, automatic welding, easy to operate |

Robotic Laser Welding Features:

1. The robot has six-axis linkage, high positioning accuracy, large processing range, and easy welding of three-dimensional workpieces.

2. Compared with the traditional argon arc welding, the laser welding speed is increased by 5 to 10 times, and the power consumption and the consumption of consumables are lower, and the welding quality is very stable.

3. The heat affected area of welding is smaller, which can better guarantee the quality of welding products.

4. Robot laser welding has good adaptability to the size and shape of welding materials and welding parts, and can realize automatic control and long-distance welding;

5. This workstation is very flexible and can weld three-dimensional curved or special-shaped workpieces. With special tooling and linkage worktables, it can realize fully automatic welding with one clamping.

6. Laser welding has less fume and dust, less radiation, and is more environmentally friendly and safer.

7. Equipped with a non-contact welding seam tracking system to detect and correct the deviation of the weld seam in real time to ensure that the qualified weld seam is obtained.

3D Industrial Fiber Laser Welding Robot Application:

Suitable for welding of stainless steel, iron sheet, aluminum, copper, alloy, steel, diamond equivalent materials or dissimilar materials, cabinets, kitchens, stair elevators, shelves, ovens, stainless steel doors and windows guardrails, distribution boxes, Stainless steel household and other industries.

iGOLDENCNC Factory View

Customer Visiting

iGOLDENCNC Service

| Pre-sales |

| > Free pre-sale consultation |

| > Free sample testing |

| > Professional CNC solutions |

| > Customer reception |

| > Fast delivery within 7 days(Available in stock) |

| > Customized machines delivered within 30 days |

| After-sales |

| > 2-year warranty |

| > Fast feedback and after-sales service in 12 hours |

| > Fast spare parts and technical assistance |

| > Free training services |

| > Special design, customized, OEM order |

Video

Robotic Welding Machine Description:

It is widely used in metal processing, machinery manufacturing and auto parts manufacturing that have processing requirements for three-dimensional workpieces.

3D Industrial Laser Welding Robot iGWL-AW Series

The robot laser welding machine is composed of a dedicated fiber laser head, a high-precision capacitance tracking system, a fiber laser and an industrial robot system. It is an advanced equipment for flexible welding of metal sheets of different thicknesses from multiple angles and multiple directions.

It is widely used in metal processing, machinery manufacturing and auto parts manufacturing that have processing requirements for three-dimensional workpieces.

3D Fiber Laser Beam Welding Robot Parameters:

Model | iGWL-RW- 1500 | iGWL-RW- 2000 | iGWL-RW- 3000 | |

Laser power | 1500W | 2000W | 3000W | |

Laser wavelength | 1080±10nm | |||

Robot | FANUC--Six-axis welding robot | |||

Maximum load on wrist | 12KG | |||

Repositioning accuracy | ±0.03mm | |||

Range of motion |

Lower arm | J1 | 340º/370º | |

J2 | 235º | |||

J3 | 455º | |||

Upper arm | J4 | 380º | ||

J5 | 380º | |||

J6 | 900º | |||

Max speed |

Lower arm | J1 | 260º/s | |

J2 | 240º/s | |||

J3 | 260º/s | |||

Upper arm | J4 | 430º/s | ||

J5 | 450º/s | |||

J6 | 720º/s | |||

Thickness of welding material | ≤4mm | ≤6mm | ≤8mm | |

Welding gap requirements | ≤0.3mm | |||

Voltage | 380V±10% | |||

Total power | ≤8kw | ≤10kw | ≤12kw | |

Gross weight | 200KG | |||

Remarks: Can be customized according to customer requirements | ||||

Comparison of Laser Welding and Traditional Welding

Welding method | Heat affected zone | Thermal deformation | Weld quality | Whether to add solder | Welding environment |

Laser welding | Smaller | Smaller | Better | No | No special requirements (except for special industries) |

Brazing | General | General | General | Yes | Overall heating |

Argon arc welding | Larger | Larger | General | Yes | Need electrodes |

Resistance welding | Larger | Larger | General | No | Need electrodes |

Plasma arc welding | General | General | General | Yes | Need electrodes |

Electron beam welding | Smaller | Smaller | Better | No | Vacuum |

Laser Welding Speed

Collimating focal length:150mm Focus length:250mm Fiber diameter:50μm Protection gas>15L/min | ||||

No. | Material | Output Power | Penetration(mm) | Speed(m/min) |

1 |

Stainless steel | 500 | 1.5 | 0.85 |

2 | 500 | 1 | 2.55 | |

3 | 500 | 0.5 | 6.8 | |

4 | 750 | 2.5 | 0.85 | |

5 | 750 | 2 | 2.55 | |

6 | 750 | 1.5 | 2.17 | |

7 | 750 | 1 | 6.8 | |

8 | 1000 | 0.5 | 8.5 | |

9 | 1000 | 3 | 0.85 | |

10 | 1000 | 2.5 | 2.55 | |

11 | 1000 | 2 | 3.4 | |

12 | 1000 | 1.5 | 5.1 | |

13 | 1000 | 0.5 | 12.75 | |

14 |

Carbon steel (low) | 500 | 1 | 1.28 |

15 | 500 | 0.5 | 5.1 | |

16 | 750 | 2 | 0.85 | |

17 | 750 | 1.5 | 2.55 | |

18 | 750 | 1 | 5.95 | |

19 | 750 | 0.5 | 7.62 | |

20 | 1000 | 2.5 | 0.85 | |

21 | 1000 | 2 | 2.55 | |

22 | 1000 | 1.5 | 4.25 | |

23 | 1000 | 1 | 6.8 | |

24 | 1000 | 0.5 | 11.05 | |

25 |

Aluminium | 500 | 1 | 0.85 |

26 | 750 | 1 | 1.7 | |

27 | 1000 | 1 | 3.4 | |

28 | 1000 | 2 | 0.85 | |

29 | Copper | 1000 | 0.3 | 1.7 |

Details Of The Robot Laser Welding Machine:

| JPT Laser We use advanced fiber lasers with a service life of more than 10w hours, low energy consumption, low failure rate, flexible fiber up to 10-15m, flexible and convenient, outdoor welding, equipped with a hard protective layer. |

| WSX Professional welding head 1. This welding head has strong advantages in aluminum alloy welding and medium power welding applications, and it is a cost-effective welding head. 2. The welding head uses a motor to drive the X, Y axis vibrating lens, with a variety of swing modes, and the swing welding allows the workpiece to have irregular welds, larger gaps and other processing parameters, which can significantly improve the welding quality. 3. The internal structure of the welding head is completely sealed, which can prevent the optical part from being polluted by dust. 4. The protective lens adopts a drawer type structure, which is easy to replace. 5. It can be equipped with various lasers with QBH connectors. |

|

Robot Six-axis LinkageThe six-axis linkage of the robot can easily realize the welding of three-dimensional workpieces. With special tooling and linkage workbench, it can realize fully automatic welding with one clamping. |

| Multi-axis mobile welding table The whole machine is designed with a thick aluminum plate, and the structure is firm High positioning accuracy and sensitive response No need to manually move the product, automatic welding, easy to operate |

Robotic Laser Welding Features:

1. The robot has six-axis linkage, high positioning accuracy, large processing range, and easy welding of three-dimensional workpieces.

2. Compared with the traditional argon arc welding, the laser welding speed is increased by 5 to 10 times, and the power consumption and the consumption of consumables are lower, and the welding quality is very stable.

3. The heat affected area of welding is smaller, which can better guarantee the quality of welding products.

4. Robot laser welding has good adaptability to the size and shape of welding materials and welding parts, and can realize automatic control and long-distance welding;

5. This workstation is very flexible and can weld three-dimensional curved or special-shaped workpieces. With special tooling and linkage worktables, it can realize fully automatic welding with one clamping.

6. Laser welding has less fume and dust, less radiation, and is more environmentally friendly and safer.

7. Equipped with a non-contact welding seam tracking system to detect and correct the deviation of the weld seam in real time to ensure that the qualified weld seam is obtained.

3D Industrial Fiber Laser Welding Robot Application:

Suitable for welding of stainless steel, iron sheet, aluminum, copper, alloy, steel, diamond equivalent materials or dissimilar materials, cabinets, kitchens, stair elevators, shelves, ovens, stainless steel doors and windows guardrails, distribution boxes, Stainless steel household and other industries.

iGOLDENCNC Factory View

Customer Visiting

iGOLDENCNC Service

| Pre-sales |

| > Free pre-sale consultation |

| > Free sample testing |

| > Professional CNC solutions |

| > Customer reception |

| > Fast delivery within 7 days(Available in stock) |

| > Customized machines delivered within 30 days |

| After-sales |

| > 2-year warranty |

| > Fast feedback and after-sales service in 12 hours |

| > Fast spare parts and technical assistance |

| > Free training services |

| > Special design, customized, OEM order |

content is empty!