Views: 17 Author: Site Editor Publish Time: 2022-02-21 Origin: Site

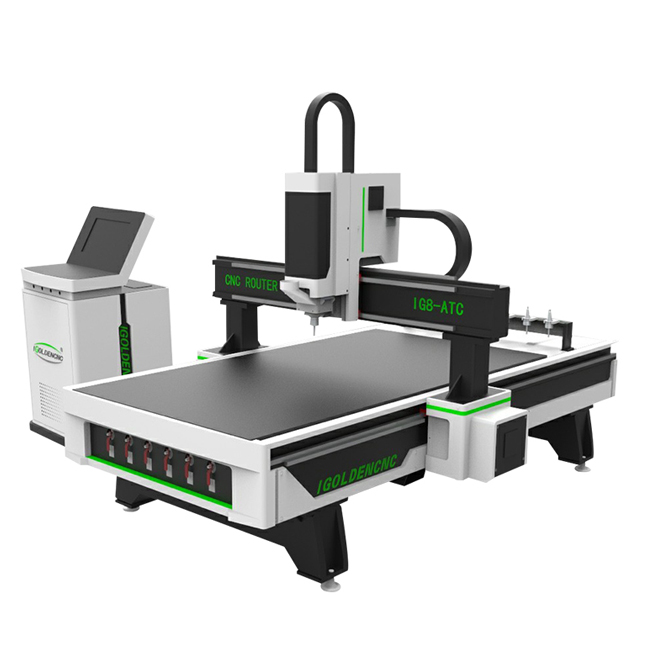

CNC router atc upgrade is the first choice for enterprises with large production volume. Compared with the traditional manual tool change production method, this type of wood CNC machine has an independent tool magazine with different tool bits. It can automatically change the required tools by computer program control without stopping work during processing. And this atc furniture can complete a series of cutting, hollowing, grooving, punching, milling grooves, milling planes and other different processing needs. Therefore, both the processing quality and processing efficiency have been greatly improved.

What we are most concerned about is the service life of the atc cnc router

After the atc cnc router is purchased back, the frequency of use will be very high, so the configuration of the engraving machine is the best configuration, which will increase the service life of the engraving machine and reduce the cost of customers, especially an economical model is needed. The engraving machine is also very functional.

Linear ATC Woodworking CNC Router with SYNTEC control system is used for decorations, musical instruments, wood crafts, wood furniture, wood door making, cabinet making, windows, tables, etc. Now the best linear ATC wood CNC router for sale at affordable price.

Automatic tool changer (ATC) CNC Router machine is suitable for the processing of various complex products or a variety of processing. It can be equipped with 6, 8, 10, 12 tools according to the different production process requirements of customers. There are two tool change modes for inline tool change and disc tool change. Widely used, including engraving, milling, chamfering, side milling, drilling, cutting, grooving, etc.

2130 4 Axis ATC CNC Router with Rotary Axis

The 2130 ATC CNC Router with Rotary Axis is equipped with a right rotation axis, multi-purpose and cost-effective, which has both flat plate carving and column engraving functions. It is mainly used for 3D engraving process, wave board processing, wooden door processing, solid wood furniture carving, solid wood art mural carving, etc.

2130 ATC 4 Axis CNC Router

The best 4 axis CNC wood engraving machine, the spindle can swing 180 degree, 8 linear tool changers can be selected to meet the needs of different processing technologies, full-scale engraving without dead angles, and can complete curved surface processing, mainly used in wood mold industry, craft industry and gift industry.

Multifunctional Atc Wood 4 Axis CNC Router Machine

The Multifunctional atc cnc router machine is attached with a rotating shaft, and the main shaft can be rotated 180°, which can be used to process various 3D products.

2060 ATC CNC Router Cnc Wood Board Cutting Machine

2060 ATC CNC Router Cnc Wood Board Cutting Machine with drum type ATC kit has no need to change tools manually during machining, drum type ATC CNC router is smart to operate the working process with rotary tool changer kit.

How does an cnc router atc upgrade work?

Once set up on your CNC machine, an automatic tool changer follows a quick set of steps to swap tools in and out. Here’s how it works.

The tool change command is given to the machine via the computer.

The tool to be changed assumes a fixed position known as the “tool change position.”

The ATC spindle moves to that position to pick up the tool.

The z-axis moves between the machine tool rack/rotary to pick up/drop off tooling.

Internally, the spindle opens or closes the chuck to exchange tooling before returning back to work.

In a matter of seconds, an ATC enables you to switch tools automatically without any need for human

Nesting CNC Router ATC Tool Changer With Drilling Wood Machine Features and Advantages:

1. Using ATC air-cooled tool change spindle with high power, it is suitable for processing complex patterns.

2. Adopting servo motor with reducer, it has the advantages of fast processing speed and high processing accuracy

3. With automatic loading functions, it effectively saves manpower and improves processing efficiency.

4.The tool magazine is installed under the gantry, which effectively improves the machining accuracy and prolongs the service life of the machine.

5. Automatic feeding, cutting and optimization, playing vertical hole, automatic cutting coherent, continuous processes, maximize efficiency output.

6. User-friendly machine control interface design. Workers can operate the machine expertly just by simple training.High efficiency of the machine help you achieve productivity leap.

7. We adopt high quality spare parts for this CNC machine such as Italian HSD Spindle, YASKAWA AC Servo system, German Becker Pump, and so on.

What are the four maintenance skills for a cnc router atc upgrade?

1. The engraving machine usually runs continuously for less than 10 hours a day to ensure the cleanliness of the cooling water and the normal operation of the water pump. The water spindle motor should not run out of water. Change the cooling water regularly to prevent the water temperature from becoming too high. If the working environment temperature in winter is too low, the water in the aquarium can be replaced with antifreeze.

2. Whenever you use the machine, pay attention to cleaning and be sure to clean the platform and transmission system of dust. Also, lubricate the transmission system (X, Y, Z 3 axes) regularly (weekly). (Note: The polishing rods of the three rods X, Y and Z are maintained by motor oil. High speed butter is added to the screw parts. If winter working environment temperature is too low, screw rod and The polishing rods (square or circular rails) must be cleaned with gasoline Clean and then add oil, otherwise excessive resistance will be created in the transmission part of the machine and the machine will be misaligned. )

3. When performing maintenance and inspection of electrical appliances, be sure to turn off the power after the monitor display is turned off and the main circuit power indicator light is off.

4. Inspect the fasteners of the engraving machine after about 3 months and tighten the connecting screws on both sides of the gantry, the tightening screws of the screw nuts, and the tightening screws of the motors on both sides.

The Application of Best cnc router atc upgrade:

Furniture: all kinds of furnitures like cabinet, door,windows,beds etc2. Office furnitures:Table, chair, sofa, stands etc3. Sign: LED light,bending letters,pvc cutting,acrylic cutting,sign letters etc4. Mould marking:wood mould.shoes mould.aluminum mould, tooth mould etc