iGR-L

iGOLDENLASER

iGR-L

| Availability: | |

|---|---|

Fiber Laser Cutting Machine Description:

Fiber laser cutting machine through the fiber laser generator to output the high energy density laser beam and focus on the workpiece surface, so that the workpiece is melted and vaporized in a moment irradiated by the superfine focus spot. It can automatically cut through the position of the movable spot of the CNC mechanical system.

Laser Cutting Machine Features:

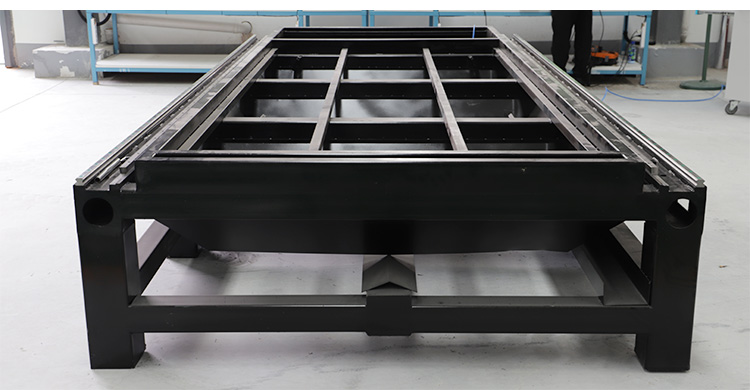

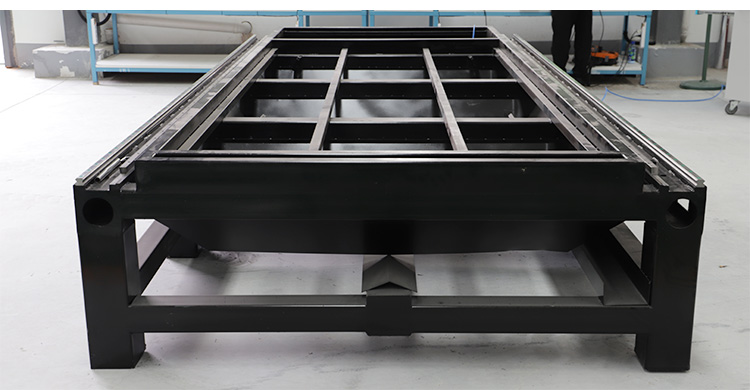

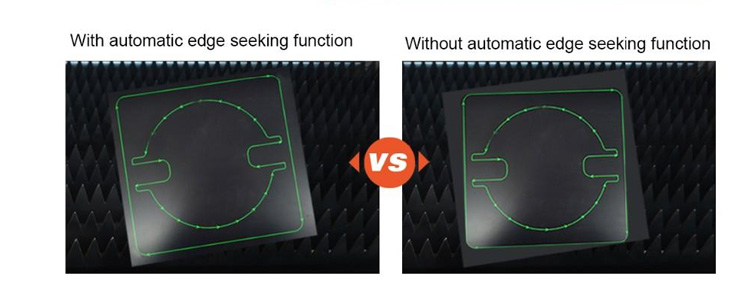

High precision. After manual aging, solution treatment and finishing, the beam has good integrity, rigidity, toughness and ductility.

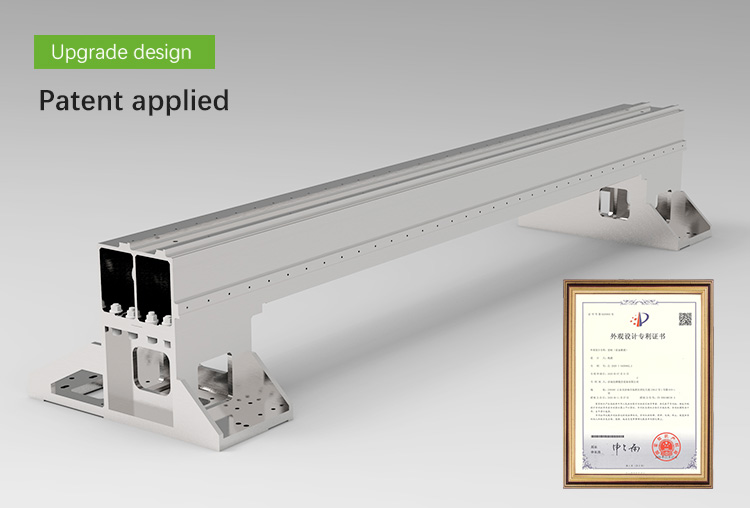

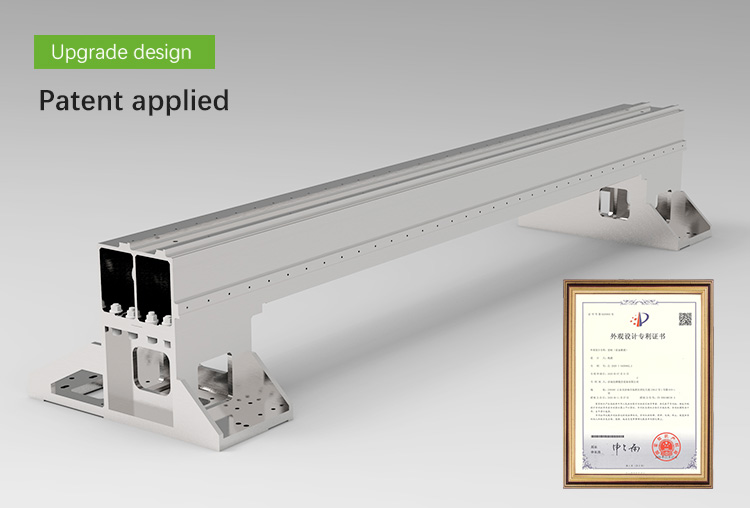

Fast speed. Aluminum alloy has the features of light weight and strong rigidity, which is conducive to high-speed movement during processing, and high flexibility is conducive to high-speed cutting of various graphics on the basis of high precision.

High efficiency. The lighter weight beam can ensure the rapid operation of the flatbed laser cutting machine, improve the processing efficiency, and at the same time ensure the processing quality.

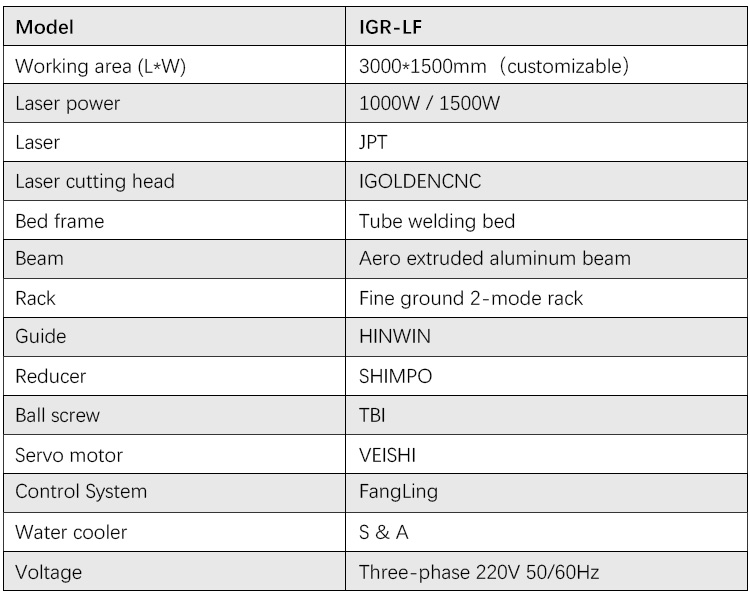

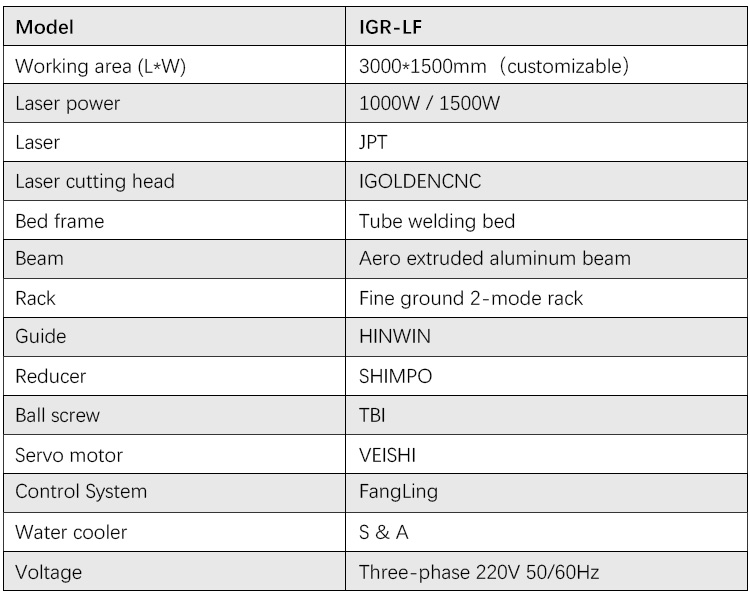

Entry-Level Laser Cutting Machine Product Parameter:

The Advantages Of Laser Cutting Equipment Over Alternative Methods Include:

Cuts non-ferrous material with ease

Reliable and fast machinery for rapid turnaround

Uses less energy when cutting – using nitrogen, oxygen, air

Cuts through the thickest of metals – including mild steel

Cut complex shapes with precise detail

Non-wearing for a flawless edge finish

İGOLDENCNC Laser Cutting Head :

The laser head has a built-in motor drive unit, and the focusing lens is driven by a linear mechanism to automatically change the position within 20mm.

The user can set continuous focus through the program to complete the rapid perforation of thick plates and automatic cutting of plates of different thicknesses and materials.

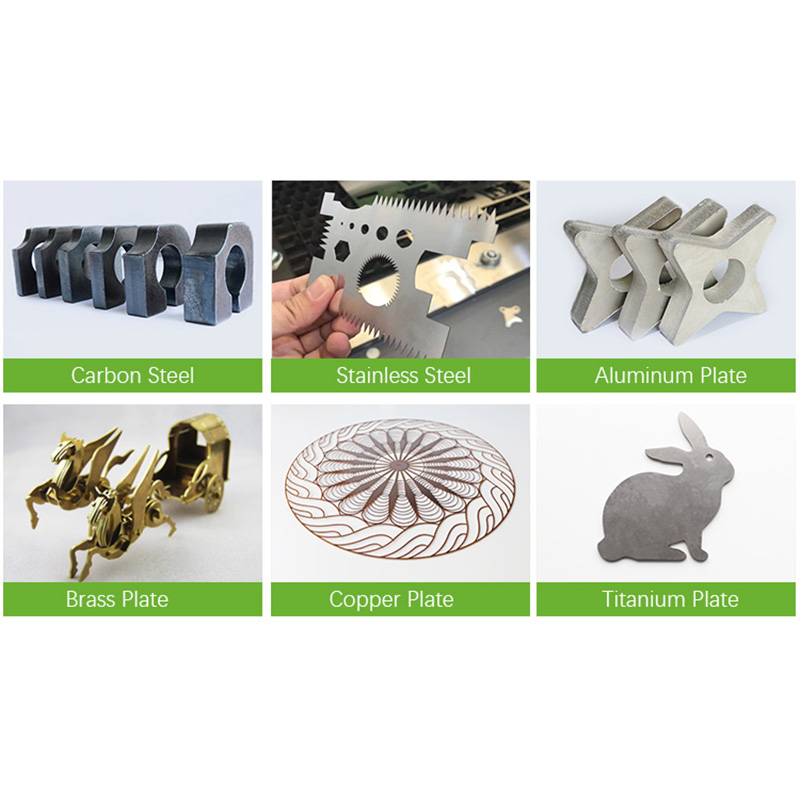

Fiber Laser Cutting Machine Application:

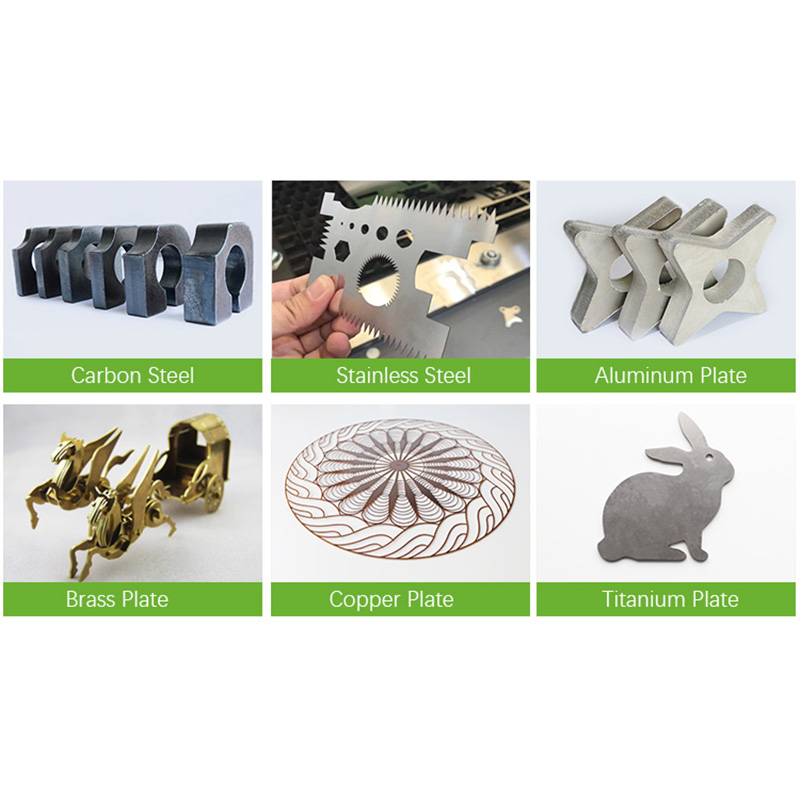

--Materials. Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, aluminum-plating zinc plate, copper, and other metals.

--Various industry. The fiber laser cutting machine is widely used in automative industry, advertising industry, kitchenware industry, sheet metal industry, cabinet industry, fitness industry etc. Professional in many manufacturing and processing industries like sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, grain machinery, textile machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising , metal processing, kitchen processing and other industries.

Fiber Laser Cutting Machine Description:

Fiber laser cutting machine through the fiber laser generator to output the high energy density laser beam and focus on the workpiece surface, so that the workpiece is melted and vaporized in a moment irradiated by the superfine focus spot. It can automatically cut through the position of the movable spot of the CNC mechanical system.

Laser Cutting Machine Features:

High precision. After manual aging, solution treatment and finishing, the beam has good integrity, rigidity, toughness and ductility.

Fast speed. Aluminum alloy has the features of light weight and strong rigidity, which is conducive to high-speed movement during processing, and high flexibility is conducive to high-speed cutting of various graphics on the basis of high precision.

High efficiency. The lighter weight beam can ensure the rapid operation of the flatbed laser cutting machine, improve the processing efficiency, and at the same time ensure the processing quality.

Entry-Level Laser Cutting Machine Product Parameter:

The Advantages Of Laser Cutting Equipment Over Alternative Methods Include:

Cuts non-ferrous material with ease

Reliable and fast machinery for rapid turnaround

Uses less energy when cutting – using nitrogen, oxygen, air

Cuts through the thickest of metals – including mild steel

Cut complex shapes with precise detail

Non-wearing for a flawless edge finish

İGOLDENCNC Laser Cutting Head :

The laser head has a built-in motor drive unit, and the focusing lens is driven by a linear mechanism to automatically change the position within 20mm.

The user can set continuous focus through the program to complete the rapid perforation of thick plates and automatic cutting of plates of different thicknesses and materials.

Fiber Laser Cutting Machine Application:

--Materials. Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, aluminum-plating zinc plate, copper, and other metals.

--Various industry. The fiber laser cutting machine is widely used in automative industry, advertising industry, kitchenware industry, sheet metal industry, cabinet industry, fitness industry etc. Professional in many manufacturing and processing industries like sheet metal processing, aviation, aerospace, electronics, electrical appliances, subway parts, automobiles, grain machinery, textile machinery, engineering machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, craft gifts, tool processing, decoration, advertising , metal processing, kitchen processing and other industries.