| Availability: | |

|---|---|

Flat Bed Fiber Laser Description:

Flat Bed Fiber Laser is an ideal entry level laser cutter among the fiber laser cuttters. This fiber laser cutting machine does not need any high purchase cost or training cost.

Fiber Laser Cutter Parameters:

| Model | iGR-FT 3015 | |

| Working area/ Tube length | 3000*1500mm/ 6000mm | |

| X axis stroke | 1500mm | |

| Y axis stroke | 3000mm | |

| Z axis stroke | 300mm | |

| Tube diameter | 20-220mm | |

| Accuracy | X, Y axis positioning accuracy | 0.05mm |

| X, Y axis repositioning accuracy | 0.03mm | |

| Speed | W axis rotate angle | n*360 |

| W axis max. ratate speed | 80rpm | |

| X, Y axis max. running speed | 150m/min | |

| U axis max. positioning speed | 800mm/s | |

| X, Y axis max. accelerated speed | 1.5G | |

| Power supply | Phase | 3 |

| Nominal voltage | 380V | |

| Frequency | 50/60Hz | |

| Protection grade | IP65 | |

| Machine body | Max. working loading | 1000kg |

| Body weight | 2600kg | |

| Size(L*W*H) | 8060*3000*1965mm | |

| Laser power | 500w/ 750w/ 1000w/ 1500w/ 2000w/ 3000w/ 4000w/ 5000w/ 6000w/ 8000w/ 10000w/ 12000w | |

| Worktable optional | 4000*1500mm/ 4000*2000mm/ 6000*2000mm/ 6000*2500mm | |

| Tube length optional | 3000mm/ 9000mm | |

The automatic lubrication system provides a fixed amount of lubricating oil for the equipment to ensure the high-speed operation of the flatbed laser cutter, with abnormal alarm and liquid level alarm functions. The system greatly improves the cutting accuracy and effectively extends the service life of the transmission mechanism.

Intelligent travel protection, automatic monitoring of the operating range of components, installation of international machine tool standard limit springs, the laser cutting head is built-in capacitor height adjustment function, collision stop, improve equipment and life safety protection, reduce the incidence of accidents, improve cutting efficiency.

Automatic alarm function for abnormal working status of equipment, and push it to the operation interface through the control center, improve the efficiency of flatbed laser cutting machine abnormal troubleshooting, reduce potential safety hazards, and reduce maintenance costs.

Flat Bed Fiber Laser Cutter Configuration:

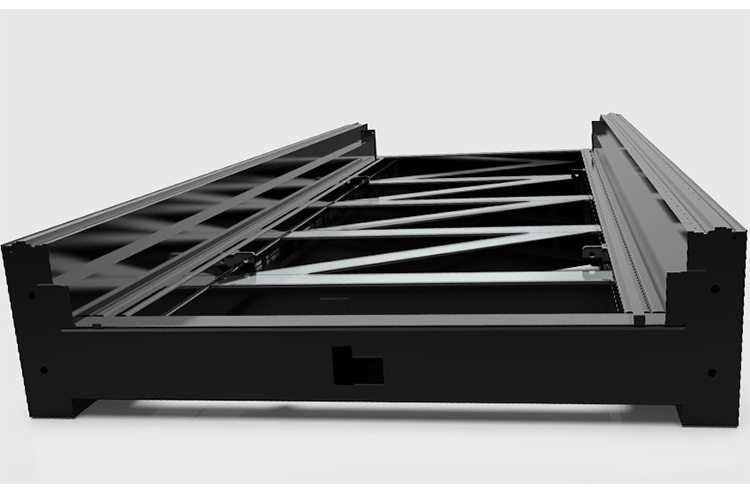

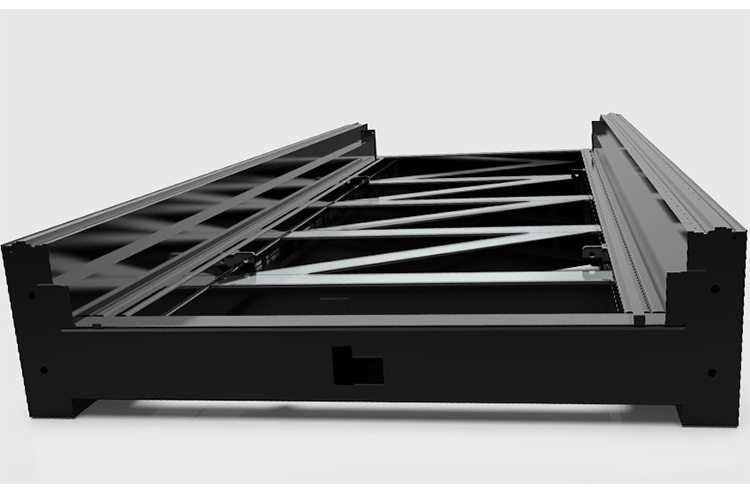

HEAVY-DUTY WELDING BED

The square tube welding bed is welded with a thick rectangular tube with a diameter of 200*200mm. The bed weight can reach 1T. The bed body is annealed and milled by a large gantry to accurately drill all installation basic holes at once.

Higher tensile strength and dimensional stability. Effectively improve the accuracy of the bed, reduce the processing error of the workpiece. Increase the resistance and stability of the guide rail.

It reduces the loss of the equipment when it is used. It keeps the precision of the cheap laser cutter for a long time and does not deform for 20 years. The affordable laser cutter has good stability and reduces the processing errors caused by the vibration of the bed.

Other suppliers: Plate welding bed, poor overall stability and low accuracy.

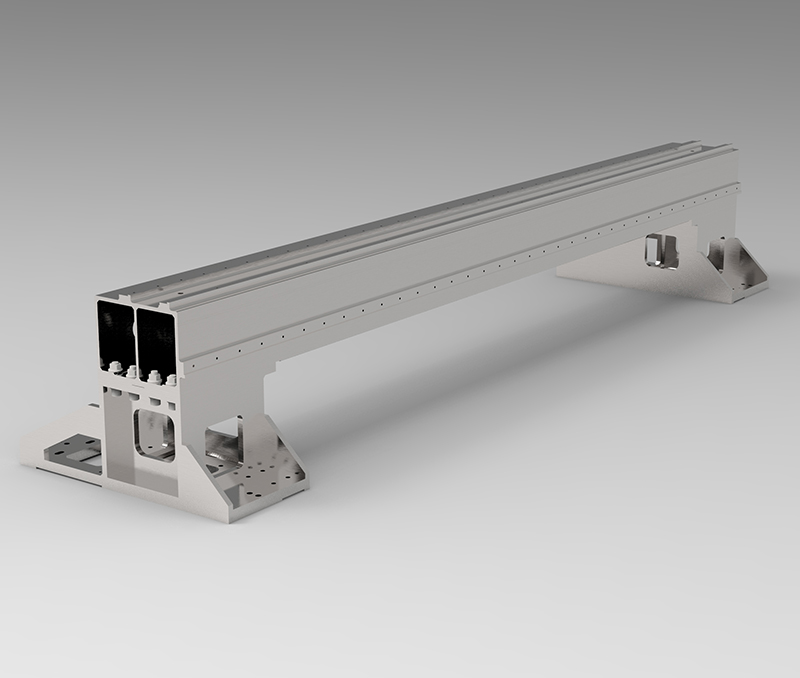

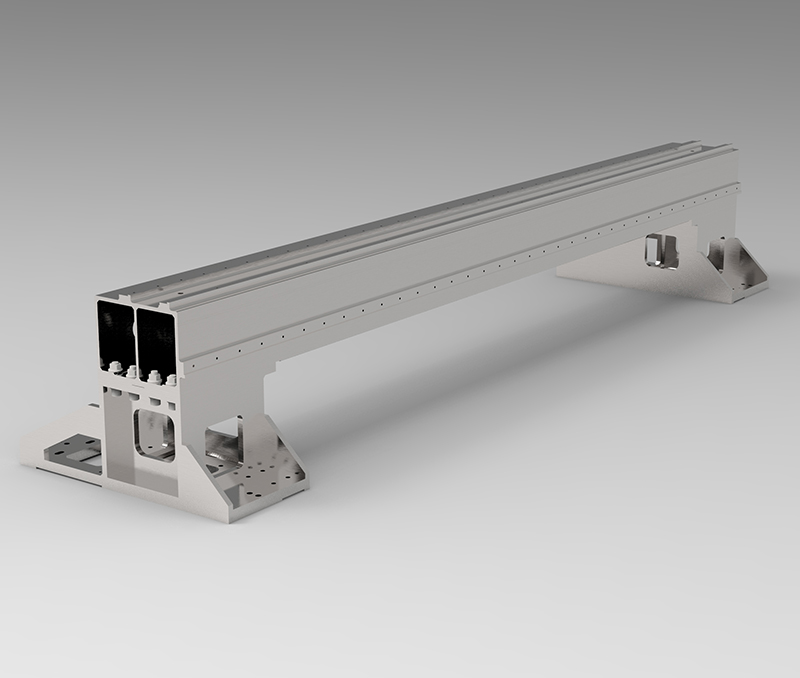

AEROSPACE ALUMINUM EXTRUSION BEAM

★ High precision. After manual aging, solution treatment and finishing, the beam has good integrity, rigidity, toughness and ductility.

★ Fast speed. Aluminum alloy has the features of light weight and strong rigidity, which is conducive to high-speed movement during processing, and high flexibility is conducive to high-speed cutting of various graphics on the basis of high precision.

★ High efficiency. The lighter weight beam can ensure the rapid operation of the flatbed laser cutting machine, improve the processing efficiency, and at the same time ensure the processing quality.

Not only can the high-speed operation of the laser cutting machine be guaranteed, but also the accuracy and efficiency of the laser cutting processing.

Effectively improve the service life and accuracy of the cheap laser cutter, reduce time cost and reduce time loss. And after using the same time limit, the aluminum beam can ensure the cutting accuracy to the greatest extent, and at the same time it can alleviate the kinetic energy of laser head during high-speed movement.

AUTO-FOCUS LASER CUTTING HEAD

The laser head has a built-in motor drive unit, and the focusing lens is driven by a linear mechanism to automatically change the position within 20mm. The user can set continuous focus through the program to complete the rapid perforation of thick plates and automatic cutting of plates of different thicknesses and materials. The compound lens group equipped with D28 integrates the light beam and optimizes the optical and water-cooled design so that the laser head can work stably for a long time.

☑ Optimized optical configuration and smooth and efficient airflow design to improve the cutting effect;

☑ Auto focus range +10~-10mm, adjustment accuracy 0.01mm, adjustment speed 100mmms;

☑ Collimation protection lens dust protection design, effectively protect the internal optical components;

☑ Extend the distance between the protection lens and the nozzle to increase the life of the lens;

☑ Drawer-type lens holder is adopted to make the protection lens replacement fast and simple;

☑ QBH connector is not limited, it can be equipped with various lasers with QBH connector.

Autofocus saves focusing time and improves work efficiency by 10 times.

Extend service life, by optimizing the structural design of the cutting head, extend its service life.

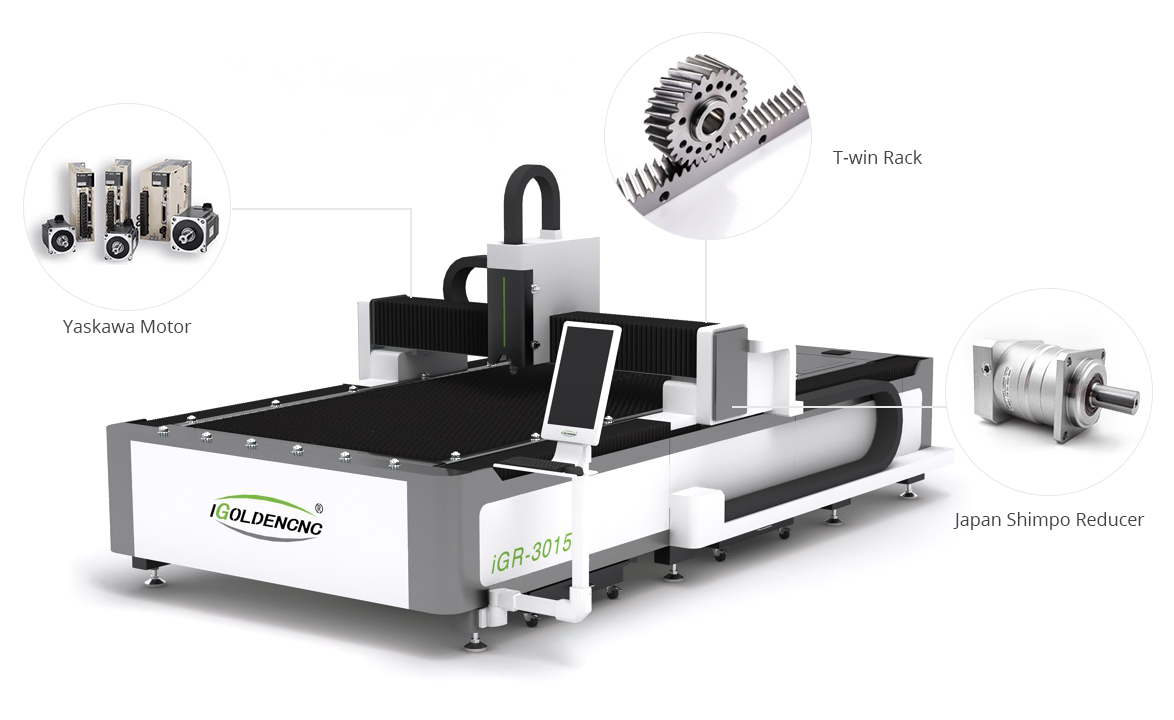

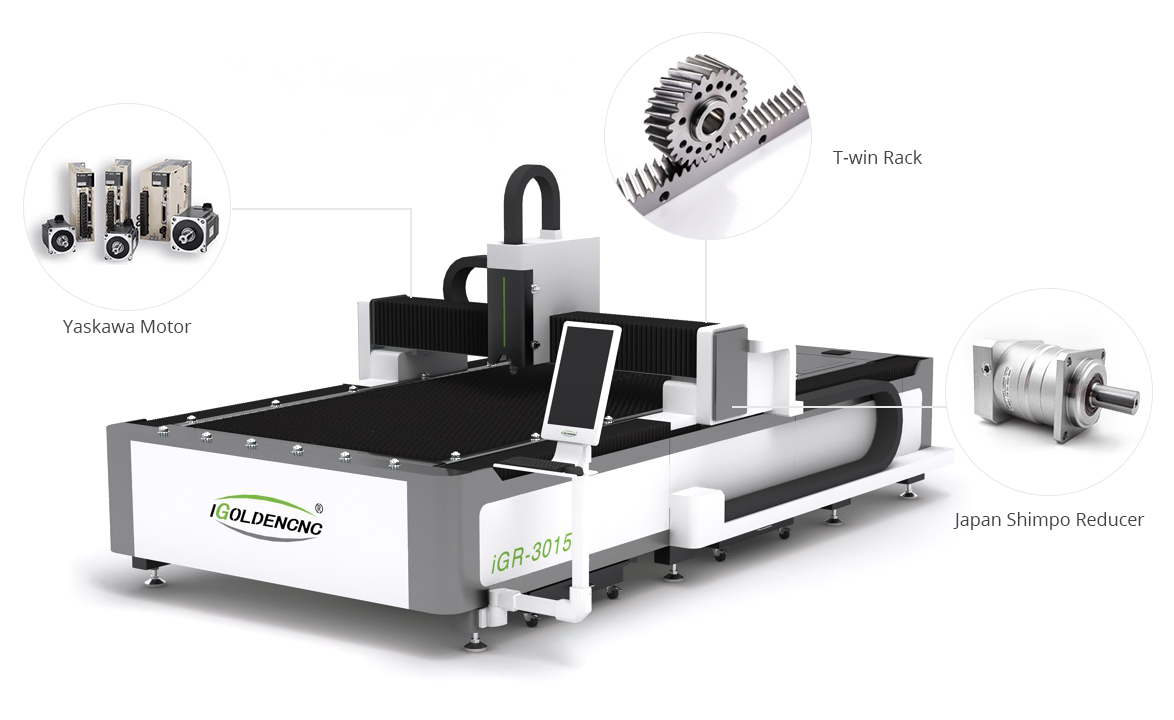

HIGH-PRECISION TRANSMISSION SYSTEM

Taiwan T-win double drive rack guide, Japan Panasonic drive motor, Japan Shimpo reducer

The positioning accuracy of the affordable laser cutter is 0.02mm, and the repeated positioning accuracy is 0.02mm.

VERTICAL LCD DISPLAY SCREEN DESIGN

The 21.5‘ vertical screen display is different from the traditional horizontal screen display. The response speed reaches 8ms, the resolution reaches 1080p, the screen ratio is optimized to 16:9, the power consumption is low, and the control software interface and human browsing habits are better adapted. In addition, it has a high brightness level and low reflectance, and the sturdy glass panel has sturdiness and durability.

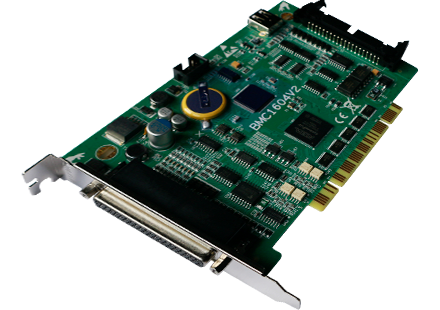

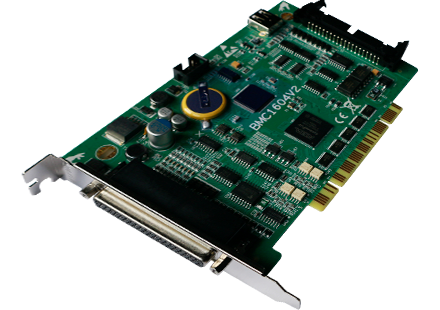

INTELLIGENT OPEN LOOP CONTROL SYSTEM

Cypcut laser cutting system is a full-featured open-loop control system launched specifically for the sheet metal processing industry.

✪ Support AI, DXF, PLT, Gerber, LXD and other graphic data formats, and accept international standard G codes.

✪ When opening and importing external files, optimization is automatically performed.

✪ Flexible and diverse automatic layout and manual layout sequence functions, a variety of array methods are available.

✪ The powerful material library function allows all process parameters to be saved for the same material to be used again.

✪ Processing breakpoint memory and positioning any point function.

✪ Fixed-height cutting, off-board following and multiple edge-finding methods.

✪ Support remote control of the system via wireless handheld box and Ethernet.

✪ One click to set flight cutting path.

✪ It is easy to install, easy to debug, excellent in performance and complete in plan.It is the fiber laser cutting control system with the highest market share at present.

OPTIONAL

SIDE ROTATION AXIS

The standard length is 3000mm/ 6000mm/ 9000m side rotation axis device, which can process square tubes, round tubes, oval tube, rectangular tube, irregular tube and other metal tube.

★ Clamp design: The electric clamp design is used on both sides, which can automatically adjust the center. The adjustable range of the diagonal is 20-220mm.

★ Automatic support installation: It adopts intelligent tube bracket design, which can solve the deformation problem during the cutting process of long tubes.

It can process both metal plates and metal pipes, one affordable laser cutter for two purposes, saving space and cost, and improving production efficiency.

OPTIONAL

FLOOR-STANDING INDEPENDENT CONTROL CABINET

Dustproof All electrical components and laser sources are built into a separate control cabinet and have a dustproof design to extend the life of the electrical components. The automatic thermostat control cabinet is equipped with air conditioning to achieve automatic constant temperature. This can prevent summer temperatures excessive damage to components.

☑ More professional electrical device assembly, strong electricity separation and weak electricity separation.

☑ Simpler dustproof, anti-static interference, good heat dissipation, easy to maintain.

☑ More convenient and easy to detect circuit faults and maintenance.

☑ Safer and independent of machine equipment, reduce equipment operation interference.

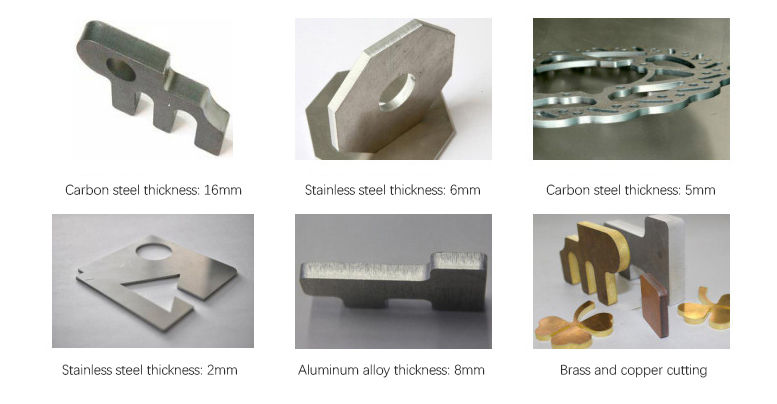

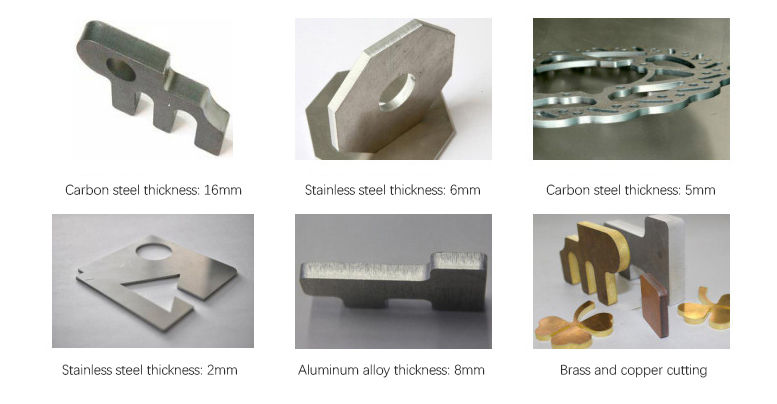

Flatbed Laser Cutting Machine Application:

Flatbed cutting machine is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate,

Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, If you equipped with the rotary axis, Metal Plate, all ok.

CNC Fiber Laser Cutting Machines are widely used in manufacture Billboard, Signs, Advertising, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

Flat Bed Fiber Laser Description:

Flat Bed Fiber Laser is an ideal entry level laser cutter among the fiber laser cuttters. This fiber laser cutting machine does not need any high purchase cost or training cost.

Fiber Laser Cutter Parameters:

| Model | iGR-FT 3015 | |

| Working area/ Tube length | 3000*1500mm/ 6000mm | |

| X axis stroke | 1500mm | |

| Y axis stroke | 3000mm | |

| Z axis stroke | 300mm | |

| Tube diameter | 20-220mm | |

| Accuracy | X, Y axis positioning accuracy | 0.05mm |

| X, Y axis repositioning accuracy | 0.03mm | |

| Speed | W axis rotate angle | n*360 |

| W axis max. ratate speed | 80rpm | |

| X, Y axis max. running speed | 150m/min | |

| U axis max. positioning speed | 800mm/s | |

| X, Y axis max. accelerated speed | 1.5G | |

| Power supply | Phase | 3 |

| Nominal voltage | 380V | |

| Frequency | 50/60Hz | |

| Protection grade | IP65 | |

| Machine body | Max. working loading | 1000kg |

| Body weight | 2600kg | |

| Size(L*W*H) | 8060*3000*1965mm | |

| Laser power | 500w/ 750w/ 1000w/ 1500w/ 2000w/ 3000w/ 4000w/ 5000w/ 6000w/ 8000w/ 10000w/ 12000w | |

| Worktable optional | 4000*1500mm/ 4000*2000mm/ 6000*2000mm/ 6000*2500mm | |

| Tube length optional | 3000mm/ 9000mm | |

The automatic lubrication system provides a fixed amount of lubricating oil for the equipment to ensure the high-speed operation of the flatbed laser cutter, with abnormal alarm and liquid level alarm functions. The system greatly improves the cutting accuracy and effectively extends the service life of the transmission mechanism.

Intelligent travel protection, automatic monitoring of the operating range of components, installation of international machine tool standard limit springs, the laser cutting head is built-in capacitor height adjustment function, collision stop, improve equipment and life safety protection, reduce the incidence of accidents, improve cutting efficiency.

Automatic alarm function for abnormal working status of equipment, and push it to the operation interface through the control center, improve the efficiency of flatbed laser cutting machine abnormal troubleshooting, reduce potential safety hazards, and reduce maintenance costs.

Flat Bed Fiber Laser Cutter Configuration:

HEAVY-DUTY WELDING BED

The square tube welding bed is welded with a thick rectangular tube with a diameter of 200*200mm. The bed weight can reach 1T. The bed body is annealed and milled by a large gantry to accurately drill all installation basic holes at once.

Higher tensile strength and dimensional stability. Effectively improve the accuracy of the bed, reduce the processing error of the workpiece. Increase the resistance and stability of the guide rail.

It reduces the loss of the equipment when it is used. It keeps the precision of the cheap laser cutter for a long time and does not deform for 20 years. The affordable laser cutter has good stability and reduces the processing errors caused by the vibration of the bed.

Other suppliers: Plate welding bed, poor overall stability and low accuracy.

AEROSPACE ALUMINUM EXTRUSION BEAM

★ High precision. After manual aging, solution treatment and finishing, the beam has good integrity, rigidity, toughness and ductility.

★ Fast speed. Aluminum alloy has the features of light weight and strong rigidity, which is conducive to high-speed movement during processing, and high flexibility is conducive to high-speed cutting of various graphics on the basis of high precision.

★ High efficiency. The lighter weight beam can ensure the rapid operation of the flatbed laser cutting machine, improve the processing efficiency, and at the same time ensure the processing quality.

Not only can the high-speed operation of the laser cutting machine be guaranteed, but also the accuracy and efficiency of the laser cutting processing.

Effectively improve the service life and accuracy of the cheap laser cutter, reduce time cost and reduce time loss. And after using the same time limit, the aluminum beam can ensure the cutting accuracy to the greatest extent, and at the same time it can alleviate the kinetic energy of laser head during high-speed movement.

AUTO-FOCUS LASER CUTTING HEAD

The laser head has a built-in motor drive unit, and the focusing lens is driven by a linear mechanism to automatically change the position within 20mm. The user can set continuous focus through the program to complete the rapid perforation of thick plates and automatic cutting of plates of different thicknesses and materials. The compound lens group equipped with D28 integrates the light beam and optimizes the optical and water-cooled design so that the laser head can work stably for a long time.

☑ Optimized optical configuration and smooth and efficient airflow design to improve the cutting effect;

☑ Auto focus range +10~-10mm, adjustment accuracy 0.01mm, adjustment speed 100mmms;

☑ Collimation protection lens dust protection design, effectively protect the internal optical components;

☑ Extend the distance between the protection lens and the nozzle to increase the life of the lens;

☑ Drawer-type lens holder is adopted to make the protection lens replacement fast and simple;

☑ QBH connector is not limited, it can be equipped with various lasers with QBH connector.

Autofocus saves focusing time and improves work efficiency by 10 times.

Extend service life, by optimizing the structural design of the cutting head, extend its service life.

HIGH-PRECISION TRANSMISSION SYSTEM

Taiwan T-win double drive rack guide, Japan Panasonic drive motor, Japan Shimpo reducer

The positioning accuracy of the affordable laser cutter is 0.02mm, and the repeated positioning accuracy is 0.02mm.

VERTICAL LCD DISPLAY SCREEN DESIGN

The 21.5‘ vertical screen display is different from the traditional horizontal screen display. The response speed reaches 8ms, the resolution reaches 1080p, the screen ratio is optimized to 16:9, the power consumption is low, and the control software interface and human browsing habits are better adapted. In addition, it has a high brightness level and low reflectance, and the sturdy glass panel has sturdiness and durability.

INTELLIGENT OPEN LOOP CONTROL SYSTEM

Cypcut laser cutting system is a full-featured open-loop control system launched specifically for the sheet metal processing industry.

✪ Support AI, DXF, PLT, Gerber, LXD and other graphic data formats, and accept international standard G codes.

✪ When opening and importing external files, optimization is automatically performed.

✪ Flexible and diverse automatic layout and manual layout sequence functions, a variety of array methods are available.

✪ The powerful material library function allows all process parameters to be saved for the same material to be used again.

✪ Processing breakpoint memory and positioning any point function.

✪ Fixed-height cutting, off-board following and multiple edge-finding methods.

✪ Support remote control of the system via wireless handheld box and Ethernet.

✪ One click to set flight cutting path.

✪ It is easy to install, easy to debug, excellent in performance and complete in plan.It is the fiber laser cutting control system with the highest market share at present.

OPTIONAL

SIDE ROTATION AXIS

The standard length is 3000mm/ 6000mm/ 9000m side rotation axis device, which can process square tubes, round tubes, oval tube, rectangular tube, irregular tube and other metal tube.

★ Clamp design: The electric clamp design is used on both sides, which can automatically adjust the center. The adjustable range of the diagonal is 20-220mm.

★ Automatic support installation: It adopts intelligent tube bracket design, which can solve the deformation problem during the cutting process of long tubes.

It can process both metal plates and metal pipes, one affordable laser cutter for two purposes, saving space and cost, and improving production efficiency.

OPTIONAL

FLOOR-STANDING INDEPENDENT CONTROL CABINET

Dustproof All electrical components and laser sources are built into a separate control cabinet and have a dustproof design to extend the life of the electrical components. The automatic thermostat control cabinet is equipped with air conditioning to achieve automatic constant temperature. This can prevent summer temperatures excessive damage to components.

☑ More professional electrical device assembly, strong electricity separation and weak electricity separation.

☑ Simpler dustproof, anti-static interference, good heat dissipation, easy to maintain.

☑ More convenient and easy to detect circuit faults and maintenance.

☑ Safer and independent of machine equipment, reduce equipment operation interference.

Flatbed Laser Cutting Machine Application:

Flatbed cutting machine is suitable for metal cutting like Stainless Steel Sheet, Mild Steel Plate,

Carbon Steel Sheet, Alloy Steel Plate, Spring steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, If you equipped with the rotary axis, Metal Plate, all ok.

CNC Fiber Laser Cutting Machines are widely used in manufacture Billboard, Signs, Advertising, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal crafts, metal art ware, elevator panel cutting, hardware, auto parts, Glasses Frame, Electronic Parts, Nameplates, etc.

content is empty!