IGA-M

iGOLDENCNC

| Availability: | |

|---|---|

Glass Milling Machine is also called CNC Glass Machining Center is designed to deliver high precision and efficiency for cutting, engraving, drilling, and slotting glass materials. Whether for industrial manufacturing, custom designs, or artistic glassworks, this CNC machine provides reliable performance and excellent processing quality.

CNC Glass Center suitables for glass drilling, glass cutting, and glass edging and other processes.Mainly used for doors and Windows factory, toughened glass factory on the door glass gap for grinding edge, such as shower room hinge, spring door clip, push and pull shift door lock hole, explosion-proof kitchen and bathroom table processing.

Glass Milling Machine is compact in design and precise in assembly. Adopt large inertia servo motor, industrial control system, constant power high-speed motorized spindle. Three (X/Y/Z) adopts high-precision rack transmission suitable for high-speed, low-speed and other cutting processing. lt has the characteristics of high machining precision and stable operation. Suitable for glass drilling, glass cutting, and glass edging and other processes.

Model | iGA-M1025 |

Work trip | 1000mm*2500mm*200mm |

Overall dimension | 1900mm*3600mm*1600mm |

Weighted bed | Thick wall square pipe welding |

Control system | Glass drilling and milling special system |

Spindle | 7.5kw drilling and milling special spindle |

Spindle speed | 0-24000 rpm |

Machining thickness | 3-19mm |

Frequency changer | Bester inverter |

Drivers and motors | DORNA servo motor (X-axis Y-axis 1.5KW, Z-axis 750W with lock) |

Work surface | 3mm steel plate +25mmPVC plate |

Reduction gear | SHIMPO |

Rack | High precision grinding rack 1.5m |

oiling | Manual oiler |

Repeated positioning accuracy | 0.025mm |

Glass fixing system | Standard configuration:2 vacuum adsorption plates +2 circular suction cups |

Operating voltage | 380V |

Loading and unloading | Auxiliary pulley |

Electrical component | Omron |

| 7.5KW water-cooled main shaft The use of powerful high-power spindle, cutting force, high efficiency, water circulation cooling, good heat dissipation, smooth and fast operation. |

| Professional glass operating system Professional control system, fast and smooth processing, can be cut, drilling, hinge, shaped cutting, edging, glass polishing and other processing. |

| Glass adsorber Standard: 2 vacuum adsorption plates +2 circular suction cups, high vacuum, large suction. |

| Loading and unloading rollers Aluminum alloy cylinder, hard oxidation, good sealing effect, high efficiency, reliable positioning, long service life. |

| Bester inverter Intelligent and efficient, strong protection, powerful function, strong anti-interference ability. |

| DORNA servo motor Good anti-interference ability, stronger stability, with high accuracy and response speed, to achieve stable operation. |

| SHIMPO reduction gear With high precision, low noise, long life, no oil leakage, large torque and other excellent features. |

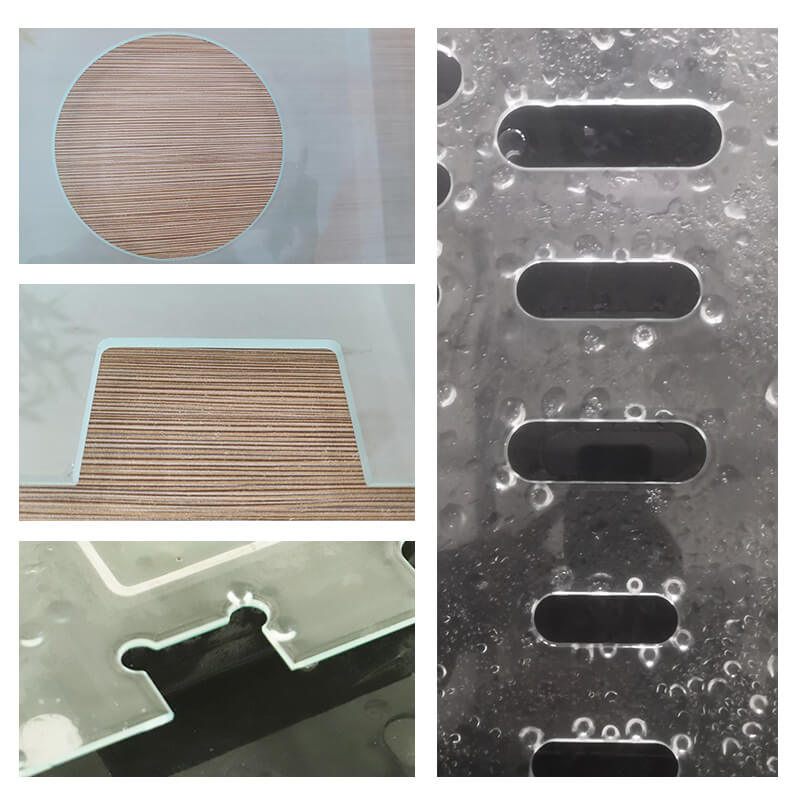

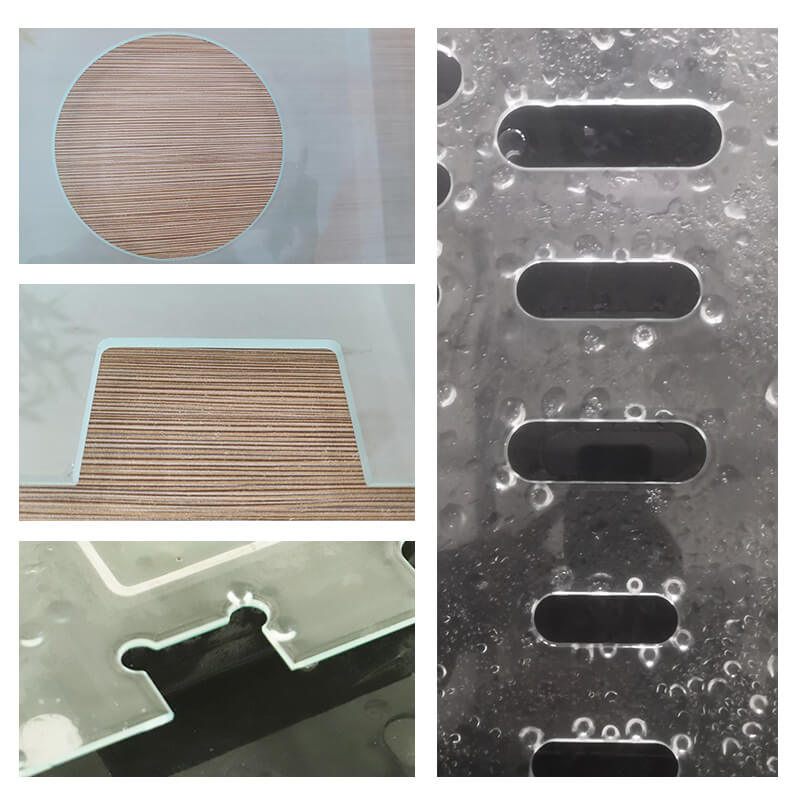

Samples

Samples

Our Glass Milling Machine plays a crucial role in the glass processing industry. It is mainly utilized in door and window factories as well as toughened glass factories. The primary function of this machine is to mill glass, with a particular emphasis on milling and molding specific shapes. These can range from simple straight lines and curves to more intricate and complex contour designs. It is specifically designed for tasks such as notch digging and grinding on door glass. For instance, it is essential for processing various components like the hinges of shower rooms, spring door clips, lock holes of push-pull doors, and the surfaces of explosion-proof kitchen and bath tables.

Our bespoke CNC glass processing services are highly efficient and reliable. They ensure remarkably consistent results, whether it's a small-scale prototype production or a large-volume manufacturing run. This level of precision and uniformity is made possible by the seamless integration of state-of-the-art CNC machinery, the expertise of highly skilled machine operators, and the utilization of advanced robotics.

Glass Milling Machine is also called CNC Glass Machining Center is designed to deliver high precision and efficiency for cutting, engraving, drilling, and slotting glass materials. Whether for industrial manufacturing, custom designs, or artistic glassworks, this CNC machine provides reliable performance and excellent processing quality.

CNC Glass Center suitables for glass drilling, glass cutting, and glass edging and other processes.Mainly used for doors and Windows factory, toughened glass factory on the door glass gap for grinding edge, such as shower room hinge, spring door clip, push and pull shift door lock hole, explosion-proof kitchen and bathroom table processing.

Glass Milling Machine is compact in design and precise in assembly. Adopt large inertia servo motor, industrial control system, constant power high-speed motorized spindle. Three (X/Y/Z) adopts high-precision rack transmission suitable for high-speed, low-speed and other cutting processing. lt has the characteristics of high machining precision and stable operation. Suitable for glass drilling, glass cutting, and glass edging and other processes.

Model | iGA-M1025 |

Work trip | 1000mm*2500mm*200mm |

Overall dimension | 1900mm*3600mm*1600mm |

Weighted bed | Thick wall square pipe welding |

Control system | Glass drilling and milling special system |

Spindle | 7.5kw drilling and milling special spindle |

Spindle speed | 0-24000 rpm |

Machining thickness | 3-19mm |

Frequency changer | Bester inverter |

Drivers and motors | DORNA servo motor (X-axis Y-axis 1.5KW, Z-axis 750W with lock) |

Work surface | 3mm steel plate +25mmPVC plate |

Reduction gear | SHIMPO |

Rack | High precision grinding rack 1.5m |

oiling | Manual oiler |

Repeated positioning accuracy | 0.025mm |

Glass fixing system | Standard configuration:2 vacuum adsorption plates +2 circular suction cups |

Operating voltage | 380V |

Loading and unloading | Auxiliary pulley |

Electrical component | Omron |

| 7.5KW water-cooled main shaft The use of powerful high-power spindle, cutting force, high efficiency, water circulation cooling, good heat dissipation, smooth and fast operation. |

| Professional glass operating system Professional control system, fast and smooth processing, can be cut, drilling, hinge, shaped cutting, edging, glass polishing and other processing. |

| Glass adsorber Standard: 2 vacuum adsorption plates +2 circular suction cups, high vacuum, large suction. |

| Loading and unloading rollers Aluminum alloy cylinder, hard oxidation, good sealing effect, high efficiency, reliable positioning, long service life. |

| Bester inverter Intelligent and efficient, strong protection, powerful function, strong anti-interference ability. |

| DORNA servo motor Good anti-interference ability, stronger stability, with high accuracy and response speed, to achieve stable operation. |

| SHIMPO reduction gear With high precision, low noise, long life, no oil leakage, large torque and other excellent features. |

Samples

Samples

Our Glass Milling Machine plays a crucial role in the glass processing industry. It is mainly utilized in door and window factories as well as toughened glass factories. The primary function of this machine is to mill glass, with a particular emphasis on milling and molding specific shapes. These can range from simple straight lines and curves to more intricate and complex contour designs. It is specifically designed for tasks such as notch digging and grinding on door glass. For instance, it is essential for processing various components like the hinges of shower rooms, spring door clips, lock holes of push-pull doors, and the surfaces of explosion-proof kitchen and bath tables.

Our bespoke CNC glass processing services are highly efficient and reliable. They ensure remarkably consistent results, whether it's a small-scale prototype production or a large-volume manufacturing run. This level of precision and uniformity is made possible by the seamless integration of state-of-the-art CNC machinery, the expertise of highly skilled machine operators, and the utilization of advanced robotics.