Views: 11 Author: Site Editor Publish Time: 2021-11-01 Origin: Site

What is a rotary axis cnc router?

Most CNC routers have at least three axes which determine the direction in which the tools and workpieces can move during the manufacturing process. A rotary axis cnc router is simply a machine that has an additional rotational axis to provide more efficient and versatile machining.

Features of rotary axis cnc router for Drilling Engraving Foam/EPS Mould:

Multifunctional (with flat table and big rotary device):

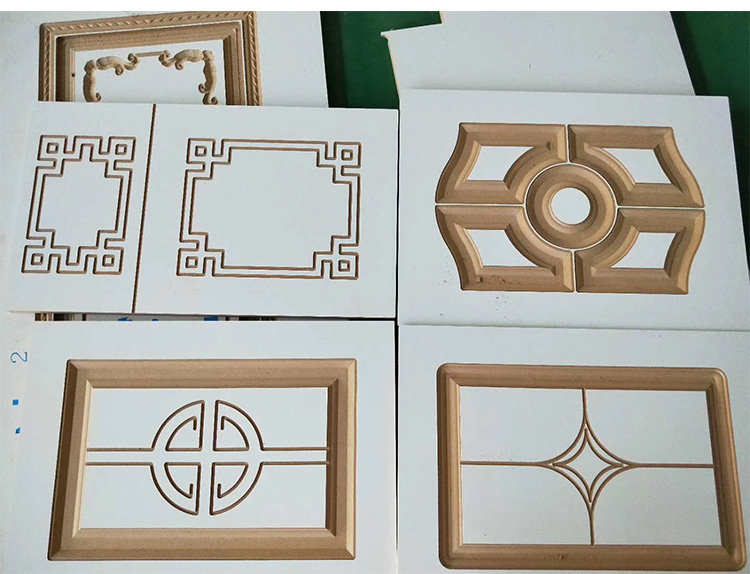

1. Engrave flat materials.

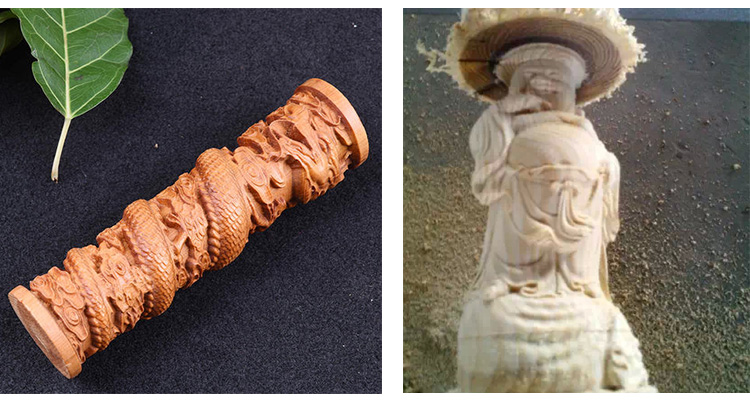

2. Engrave column materials, rotary cnc foam cutting, rotary mould making.

3. Engrave and cut soft materials: foam, MDF, EPS, PVC, wood, acrylic, etc.

4. Engrave and cut hard materials: stone, marble, granite.

5. With low table, the Z axis working space up to 1000mm, could stand heavy materials.

6. 4 axis system could engrave complex sculptures, 3D carving.

7. Auto tool changer spindle, save time when change cutters.

9. Italy HSD 9KW Air cooling spindle, auto tool change, powerful and long cutters can be hold.

10. Japan Yaskawa high Power Servo motors and drivers.

• Manually move the bit of the knife so that it is close to the live center on the tailstock.

• Push the tailstock gently to the router bit.

• Move the tip of the knife very slowly to bring it close to the central spike, and stop when the end touches the spike

• Use the combination key ON/OFF + C- to clear the coordinates of the Z-axis. Then use the combination key ON/OFF + C+ to clear the coordinates of the X-axis.

• Press Z+ to raise the tool.

• Push the tailstock toward the workpiece; tighten the bolts to keep the tailstock in place.

• Use the rotation wheel to make the spikes hold the workpiece, and then lock the thimble.

• Press the C+ key to turn the square wood to level on the rotary table.

• Manually move the tool to a suitable position.

• Use the key combination ON/OFF + C+ to clear the coordinates of the Y-axis.

• Now, we have completed the setting of the workpiece origin. The coordinates of the four motion axes X/Y/Z/A on the controller are all zero.

• Press the RUN key to enter the file list; then move the cursor to the desired file and press the OK key. The working parameter setting dialog box appears.

• Set appropriate processing parameters(press DELETE key to set the value)

• After setting the parameters, press the OK button, the system checks the code, and then

rotary axis cnc router applications:

Woodworking industry: door, furniture, loudspeaker boxes, musical instruments, etc.

Advertising industry: 3D billboards, signage, medals, badges, traffic signs, letter punches, logos, etc.

Model industry: various 3D models, landscape models, exhibition models, architecture models, car models, etc.

Sculpture: human sculptures, character sculptures, fauna and flora sculptures, etc.

Film industry: movie props, activity props, etc.

Other industries: cutting and curving the 3D surface and outline of gift wrapping, tabletops, sports equipment, wood products, etc.