Views: 25 Author: Site Editor Publish Time: 2022-12-27 Origin: Site

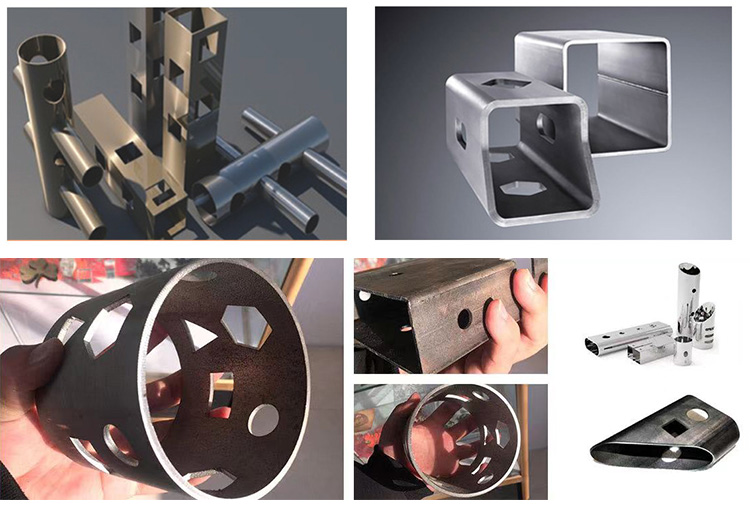

Tube fiber laser cutting machine is specially designed for pipes, easy to operate. This fiber laser cutting machine improves cutting quality and cutting efficiency. The fiber laser cutter is widely used in sports equipment, various types of pipe, water pipes, oil pipelines and other industries.Our tube laser cutter is the ultimate way to cut your metal tubes with ease. We can cut all kinds of square or round tubes and it is super quick, reliable and efficient. It uses less energy when cutting – using nitrogen, oxygen or air for the process. It is suitable for cutting through thick metals such as mild steel and even allows you to cut complex shapes with precision detail that no other method can do.

The Tube laser Cutting machine is designed to cut and engrave on square, rectangle, hexagonal or round tubes up to 220mm diameter and up to 6000mm long. It can be used for various tube-based applications such as graphic art, model building, games design and specific needs of industry.

Fast and easy to use, the Easy End Cuts can produce complex geometry on the tube ends, including a cope, fish mouth, and tab and slot. Using the laser on tubes is much faster, cleaner, and cheaper than using traditional hand or power tools. The fit-up between tubes comes out perfect every time.

1) One-click chuck opening and automatic centering will reduce the waiting time for loading and unloading.

2) Pneumatic open clamp: with large and constant clamping force, the heavy pipe is not loose or slipped, which guarantees the cutting accuracy.

3) The special support frame can avoid the sagging deformation of the pipe, improve the cutting accuracy, and prolong the service life of the chuck.

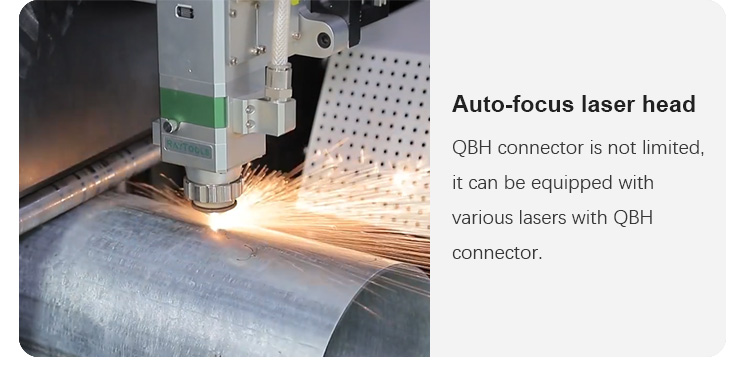

both the collimating lens and the focusing lens group are cooling accessories. Besides, the cooling airflow nozzle is added, which effectively protects the nozzle and the ceramics and prolongs the working time.

through the 35 mm aperture, the interference of stray light is effectively reduced.

without human interference, the focusing speed can reach 10m/min, and the repeatability is about 50 microns.

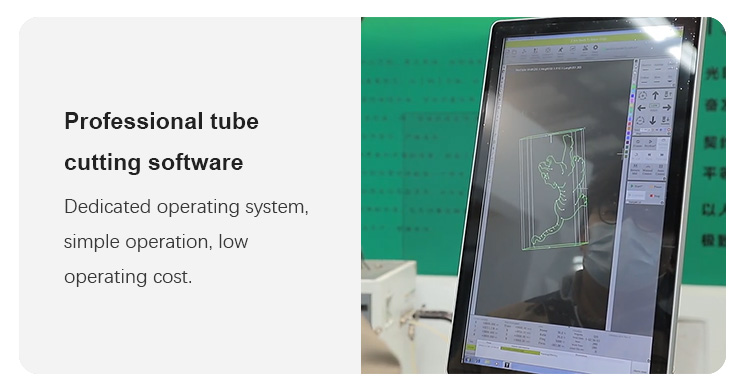

It is a professional tube cutting system, which can realize automatic centering and eccentric compensation of metal pipes to ensure cutting accuracy.

It can reduce the residual material and save the production cost.

The corners are not burnt, and the section quality is good.

The laser cutting machine is a highly reliable and virtually maintenance-free machine. It is suitable to be used in most industrial applications, including the manufacturing of custom plaques, signs and logos. The tube laser cutter can ease your work processes by cutting all kinds of metal materials with a simple drag-and-drop process, if you want to know the tube laser cutting machine price, welcome contract us freely contract us now >>

Highly dustproof :

Fully enclosed package light path, the possibility of lenscontamination is almost zero

Efficient water cooling:

The focusing lens, collimating lens and nozzle havebuilt-in cooling function, which can solve the problem ofcutting heating.

Support the setting of a separate corner process to improve the quality of pipe

Corner cutting Track accuracy 0.02mm

Positioning accuracy : 0.001mm

Repeat positioning accuracy: 0.003mm

COOLING SYSTEM Brand:wuhan hanli chiller

Cooling the laser and cutting head

Dual temperature and dual control

CNC tube cutter are designed to handle everything from thick-walled steel tubing to thin walled aluminum, and everything in between. Use it to make short pieces, long runs of tube or tube sheets on a flatbed table or in an automated cutting cell. Our Sheet Supported systems can support almost any size or shape of metal or plastic with very little setup.

Laser Tube Cutting Machine Parameter Configuration:

Model | IGR-T |

Chuck | ①240 front and rear dual pneumatic chucks; ②Range of clamping pipe diameter: 20mm-240mm; ③Transmission mode: gear transmission; ④Rated speed: about 80r/min; (For round pipes according to the outer diameter, for rectangular pipes according to the largest diagonal) |

Bed | Tube welded bed |

Motor | Yaskawa Servo Motor |

Reducer | SHIMPO Reducer |

Rail | TaiWan HIWIN |

Rack | T-WIN helical gear |

Y-axis travel | ≈7m, applicable tube length ≤6m |

X-axis travel | 240mm |

Z-axis travel | 220mm |

Support form | Pneumatic variable diameter wheel support |

Rated travel speed | Y-axis about 40m/min, XZ-axis about 30m/min |

Dimensions | 12.5m(L)×2.15m(W)×2.5m(H) |

System | Cypcut Laser cutting system |

Laser head | RayTools BM109 |

Laser | Raycus 1.5KW |

Operation console | Industrial computer + touch screen |

Fiber laser pipe cutting machine is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc.

Precision is another advantage when working with laser-cut metal tube. However, despite being a standard method, metal is a material which needs extra consideration. In comparison to other types of cutting, laser-cutting metal parts can bring a person or company, the most incredible designs for laser cut metal parts. Not to mention, the outstanding accuracy in cutting with smooth traces and edges. Laser cutting beams out highly concentrated power which make fine, accurate cuts. Indeed, when the job comes to Metal Tube Laser Cutting, we can give you the impeccable, quality-enhanced cut you’re looking for. To us, laser cutting can’t be any more difficult than karate lessons.

Fiber laser pipe cutter is widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.

content is empty!