Views: 19 Author: Site Editor Publish Time: 2022-03-23 Origin: Site

This monoblock bridge saw is a quality, qurability, cost effective, energy efficiency, look forward, green manchine, This bridge saw can process marble, granite. synthetic stones and more stones, CNC bridge saw is a fully interpolated 5 axis bridge saw. The Y axis is moved by a gantry system. This guarantees a perfect square of the bridge. Automatic head rotation from 0° to 400° combined with automatic blade tilting from 0° to 90° makes it suitable for large production runs, at the same time containing costs.

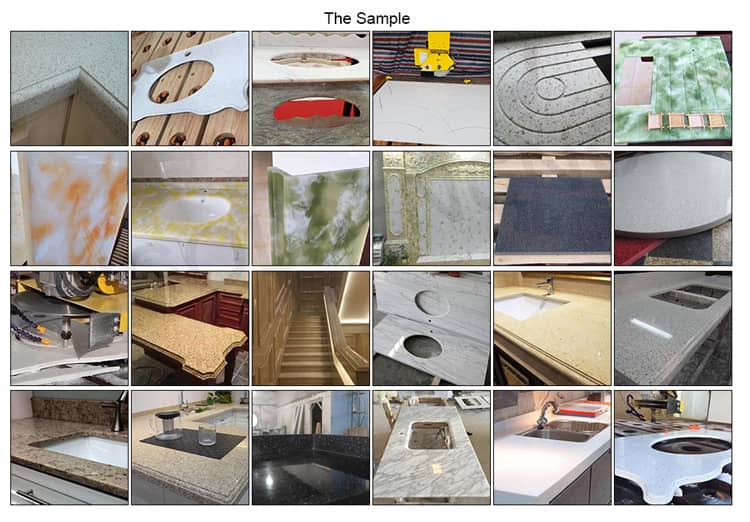

When choosing a stone bridge saw machine, the following factors should be considered: the size and weight of the stone to be cut, the thickness of the stone, the type of stone, the shape of the stone, and the required processing accuracy. In addition, the stone bridge saw machine should be easy to operate and have good cutting quality.

5 axis bridge saw come in a variety of size and power configurations. An entry level or “standard†saw for a shop producing one to three kitchens a day usually has a motor ranging from 10 to 15 horsepower. Larger, production-oriented saws usually have a 20-horsepower motor. The smaller saws will usually do a good job of cutting material up to 3 cm thick, while the larger saws are needed to cut thicker slabs or blocks of material such as limestone, granite and marble used for monuments, headstones, signs and industrial applications. While saws for these applications may have blades up to 36 or 48 inches in diameter, saws for countertop fabricators seldom exceed 24 inches. Larger blades permit faster surface speeds for faster cutting, but require a more powerful motor to overcome the reduction of torque needed for hard or dense materials such as granite.

features of Bridge Saw Stone Cutting Machine

1. It adopts 5 axis bridge cutting head, which is independently researched and developed and adopts the cast rotating bracket. This ensures good stability and flexibility during operation.

2. This bridge saw uses a high-precision RV reducer, ensuring better rotating precision of the cutting head.

3. It has built-in CAM software in the control system for the convenient of drawing designs and programming. Besides, it’s easy to learn the software to make designs.

4. The worktable can flip automatically up to 80 degrees, reducing human labor and facilitating the unloading process.

5. This bridge saw is ideal for cutting slabs of quartz, marble, granite and stone.

The bed of the bridge saw CNC machine tool is completely surrounded by sheet metal and is protected by an integral stainless steel water tank to ensure that the bed is not corroded by dust and water and improve the service life of the machine. The bed is seamlessly welded with high-quality steel structure, and the gantry is processed by the machining center after being reinforced by generous square tubes to ensure that the gantry has sufficient stability during processing.