Views: 14 Author: Site Editor Publish Time: 2022-01-14 Origin: Site

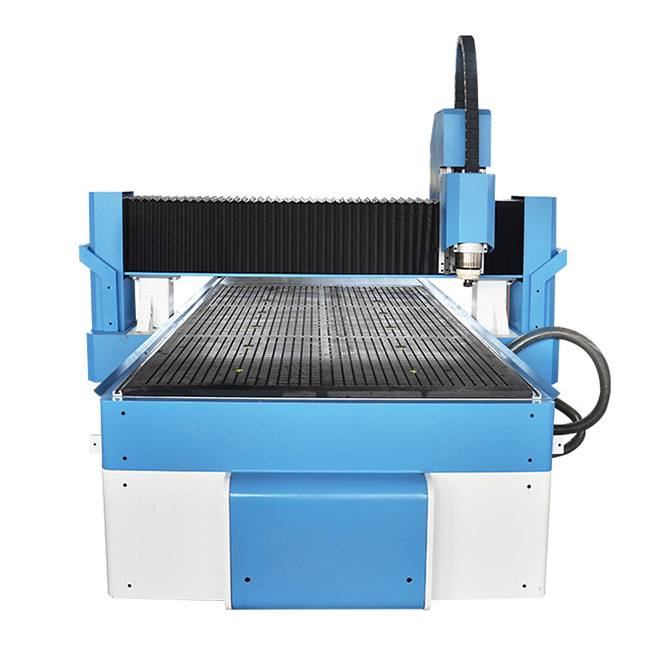

This is one of the latest China CNC router machines in 2020. Its shape is very novel. The machine is surrounded by lights, which makes your processing workshop very beautiful. It can perfectly realize wood cutter, acrylic cutter and other materials cutting, meanwhile the computer wood router machine can do engraving, carving, drilling, cutting, milling, grooving work, and many other different works. You can use DSP or Mach 3 To realize the control of the machine.

Acrylic CNC Cutting Machine is a high-tech automatic computer engraving equipment that can engraving characters on two-color board, PVC and Chevy board.

Can quickly engrave plexiglass, relief, lettering, cutting and pattern line engraving;

The pursuit of automation makes the machine conform to this trend.

Advertisement engraving machine can also engraving words, painting and abstract patterns on density board and solid board to meet the needs of personalized home decoration and tooling art design. It is a high-end engraving and processing equipment for advertising companies, decoration companies and handicraft industries.

CNC Acrylic Cutter Features

-- Advanced structure design with hot-working treatment makes performance stably and durably.

-- X.Y.Z adopting the imported ball screw, rigorous testing by the laser interferometer to ensure processing accuracy.

-- High-power drive motor fit high-performance Micro-stepping dirver make sure the machine continuous normal operation in long time.

-- Software Compatibility: Compatible Type3/Casmate/Artcam / Wentai / golden eagle etc.

Working principles of the Acrylic CNC machine:

CNC acrylic cutting machine relies on the high-speed rotation of the cutting head driven by the motor spindle. It cuts and engraves the acrylic material fixed on the worktable through the tool according to the processing material. And the machine can also engrave various plane materials or 3D embossing graphics according to the designs on the computer. And it can realize automatic cutting operation.

Step-by-Step Guide on Cutting Acrylics

Now, when you’ve chosen the acrylic, bit, and design, begin with cutting acrylic.

Step 1:- First things first, you’ve to set the feed rate according to the bit size. The most recommended range is between 75-300 IPM. High feed rates work best with large-sized bits. Smaller bits need a lower feed rate.

Step 2:- In this step, you’ve to set the RPM. The recommended value is 18,000 RPM for optimizing the spindle’s ability to cut through the acrylics, without melting the acrylics.

Step 3:- In the third step, you’ve to set the cutting depth. Experts suggest that cutting depth must be 1/2 of the diameter of the bit. It prevents the bits from breaking.

Step 4:- In the fourth step, you’ve to begin cutting with a ramp. You can select the option within the software. Opting for ramping rather than plunging is to deter distortion

Step 5:- Now, you’ve to secure the acrylic material on the CNC router table.

Step 6:- Finally, run the CNC router for cutting acrylic in a design you want.

Acrylic CNC machine application Industries:

Wood processing: processing of various furniture such as door, window, cabinet, craft wood door

screen and so on.

Advertisement: engraving and cutting various labels and number plate.

Art craft: engraving characters of any languages and graphics on souvenirs.

Applicable materials:

Wood, aluminium board, plastic, density board, wave board, PVC, acrylic,crystal, light marble and

other nonmetal materials ect...

Prccessing effect:

It can manufacture the following effects: relief, shadow, enchasement and so on.